Texas DTF printing is redefining how small businesses and hobbyists approach garment decoration. This introduction to Direct-to-Film printing in the Lone Star State explains what DTF is, how it works, and why it’s become a go-to method for producing vibrant, durable custom apparel. If you’re new to Direct-to-Film printing (DTF), you’ll learn the terminology, the essential equipment, and the step-by-step workflow that turns blank shirts into eye-catching designs. This guide is tailored to readers in Texas but is broadly applicable to anyone curious about Direct-to-Film processes and DTF vs DTG comparisons. Whether you’re selling online or at local markets, understanding DTF film and ink options, along with proper DTF printer setup and heat press for DTF, helps you confidently launch your decoration projects.

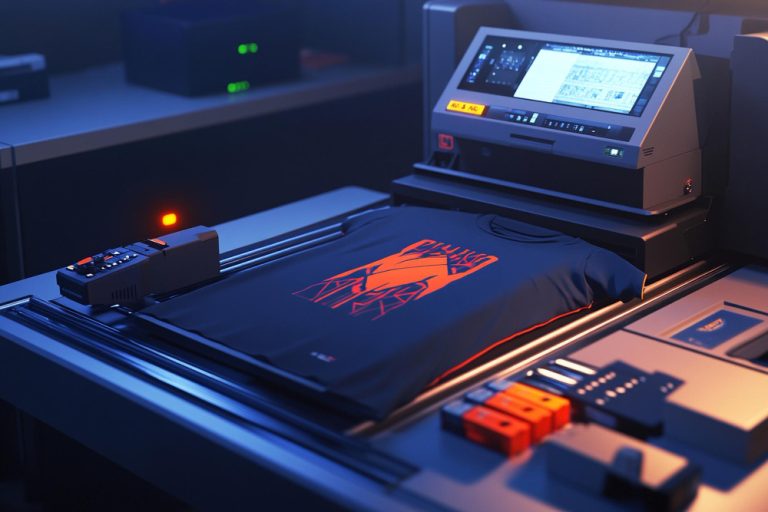

Beyond the brand name, the concept can be described as a film-based transfer method that uses pigment inks on textiles with a clear, reusable film. This LSI-friendly framing covers the adhesive powder, curing step, and heat press that together bond the design to fabric. Think of it as a digitized design being materialized through a streamlined workflow suitable for on-demand apparel and small runs. When planning, consider compatible DTF film, ink compatibility, and a reliable heat press setup to ensure consistent results across fabrics and colors.

Texas DTF Printing: A Practical Gateway to Direct-to-Film Success

Texas DTF printing makes Direct-to-Film a practical and accessible option for small businesses and hobbyists in the Lone Star State. This approach centers on Direct-to-Film printing to produce vibrant, durable transfers that perform well on cotton blends and dark fabrics, delivering a soft hand feel and strong wash resistance. For beginners, the workflow from concept to finished garment is approachable, with a clear path through selecting a printer, preparing film, and applying adhesive powder without the more complex pretreatment steps seen in other methods. Focusing on the core components—DTF film and ink, curing, and a reliable heat transfer process—helps Texas shops scale from single designs to on-demand runs.

Understanding how DTF compares to DTG can help decision-makers choose the right decoration method. In many cases, DTF film and ink offer broader fabric compatibility, easier inventory management, and better performance on darker garments, making it a robust alternative to DTG for small batches and varied designs. A solid DTF printer setup emphasizes pigment inks designed for film, a compatible transfer film, and a controlled heat press for DTF to ensure color fidelity and repeatable results. By dialing in temperature, time, and pressure, beginners can reproduce bold, consistent designs across multiple orders.

Mastering Your DTF Workflow: From Film to Fabric with the Right Heat Press and Ink Choices

The success of any DTF project hinges on choosing high-quality DTF film and ink combinations that deliver sharp details, smooth gradients, and strong adhesion. The right pairing reduces issues like white specks and color shifting, especially on dark fabrics. Equally important is a robust color-management plan—using ICC profiles and calibrated settings—to translate screen designs to real textiles, ensuring consistent results across different garment colors and weights. These considerations align with a practical, Descriptive view of the workflow and emphasize the importance of materials in achieving predictable outcomes.

Mastery comes from refining the DTF printer setup, the curing stage, and the heat press for DTF. With a well-tuned heat press, you can adjust temperature, dwell time, and pressure to suit diverse fabrics—from light tees to heavy hoodies—while preserving image integrity. Documenting your standard operating procedures and continuously testing designs against DTG equivalents helps you optimize your process, improve efficiency, and deliver reliable results for customers throughout Texas.

Frequently Asked Questions

Texas DTF printing: DTF vs DTG – how does Direct-to-Film printing compare for small runs?

In Texas, Direct-to-Film printing (DTF) generally offers versatility across fabrics, faster setup for multiple designs, and less pretreatment, making it a practical choice for small-batch orders. DTG prints directly on fabric and can deliver a very soft hand on light-colored garments, but often requires pretreatment and can have higher per-piece costs for small runs. Overall, DTF vs DTG in Texas shops often favors DTF for mixed fabrics, darker garments, and quicker changeovers, while DTG remains strong for premium hand feel on light tees. Choose DTF for broader compatibility and faster turnarounds; choose DTG when the primary fabrics are light and you want maximum detail with minimal layers.

Texas DTF printing for beginners: What should I know about DTF printer setup, DTF film and ink, and selecting a heat press for DTF?

For Texas DTF printing beginners, start with a printer setup that supports pigment inks and is compatible with DTF film, and use color management tools to maintain consistent output. Test different DTF film and adhesive powder brands to find reliable adhesion and print quality. For heat press for DTF, choose a press with adjustable temperature, time, and pressure, and follow manufacturer guidelines for your film and ink. A repeatable workflow from design to transfer and a clean, vented workspace help produce durable, vibrant results across fabrics.

| Topic | Key Points |

|---|---|

| What is Direct-to-Film (DTF) Printing? | Transfer-based method using pigment inks on a film; film is coated with adhesive powder; heat transfer yields vibrant images on many fabrics including dark garments; soft hand feel. |

| Core Components of a DTF Workflow | – Printer and inks; DTF film; adhesive powder; curing/heating system; heat press; post-processing tools |

| DTF vs DTG: Why Some Texas Shops Choose Direct-to-Film | – Works on broader fabric range (including dark fabrics); fewer pretreatment steps; better for small runs and multiple designs; easier inventory management |

| Getting Started: Equipment and Setup for Texas DTF Printing | – Printer with pigment inks; compatible film and powders; curing/heat transfer; software and color management |

| Setting up your workspace for Texas DTF printing | – Clean, ventilated area; dedicated prepress; temperature-stable environment; humidity considerations in Texas |

| The DTF Printing Process: From Design to Finished Garment | – Design prep; print onto film; apply adhesive powder; cure; transfer with heat; finish and inspect |

| Materials and Quality: Inks, Film, and Powder | – Inks: pigment inks compatible with printer/film; color gamut and wash durability – Film: clear/transfers sharply; adhesive opacity affects dark fabrics – Powder: uniform coating and reliable melt under heat |

| Prepress, Color Management, and Calibration | – Calibrate printer with color targets; use ICC profiles; account for fabric color and film transparency; maintain color consistency across batches |

| Tips for a Successful DTF Project in Texas | – Run test prints; control heat and pressure; store materials properly; clean and maintain equipment; build a diverse portfolio |

| Common Challenges and Troubleshooting | – White specks from uneven powder or poor curing; faded colors on dark fabrics; peeling transfers; sticky finishes; adjust cure time, powder application, and heat. |

| Cost, ROI, and Scaling with Texas DTF Printing | – Initial setup varies; ROI improves with consistent orders; scale via second printer or larger press; emphasize repeatable workflows and color management |

| Getting Started: Practical Next Steps for Beginners in Texas | – Define niche; start with a tested starter kit; learn the end-to-end process; build online presence; stay compliant and safe |

| FAQs | – Is DTF printing suitable for beginners? Yes with the right kit and workflow. – Can DTF prints be washed repeatedly? Yes with proper curing. – How does weather affect DTF? Humidity and temperature matter. – What fabrics work best? Cotton and blends. |

Summary

Texas DTF printing offers a practical, scalable path for producing high-quality, durable custom apparel. The Direct-to-Film workflow provides flexibility for one-off designs and small runs while delivering vibrant color and a soft hand feel. By understanding the core components—inks, film, powder, and heat transfer—and by paying attention to color management and curing, the beginner can build a reliable Texas DTF printing operation. Whether starting a small business, adding a new service to an existing shop, or pursuing a personal passion, DTF provides a clear, cost-effective route to turning ideas into wearable art. Embrace the learning curve, test your processes, and watch your Texas DTF printing venture grow.