DTF Transfers are transforming how creators decorate fabrics, offering a beginner-friendly entry into direct-to-film printing. This introductory guide covers essential concepts, including DTF transfer methods and how to plan successful, durable designs. You’ll learn the core workflow and best practices for presenting images on fabric with confidence, including file setup, color management, and layout considerations. The guide emphasizes careful preparation, effective pre-pressing, proper curing, and consistency to help you achieve a soft hand feel and lasting results across projects. With practical steps, clear visuals, and beginner-friendly language, you’ll gain the foundation needed to start your first DTF project and iterate quickly.

Beyond the name, this approach relies on printing designs onto a specialist film, then bonding the image to textiles through heat and pressure. Without using pre-cut vinyl, the method preserves color accuracy and detail, making it popular for small runs, custom orders, and creative experimentation. Key steps include design preparation, substrate selection, and choosing compatible powders and films to ensure long-lasting results. As you explore this technique, consider related terms such as digital textile transfer, film-based printing, and garment decoration workflows to broaden your understanding.

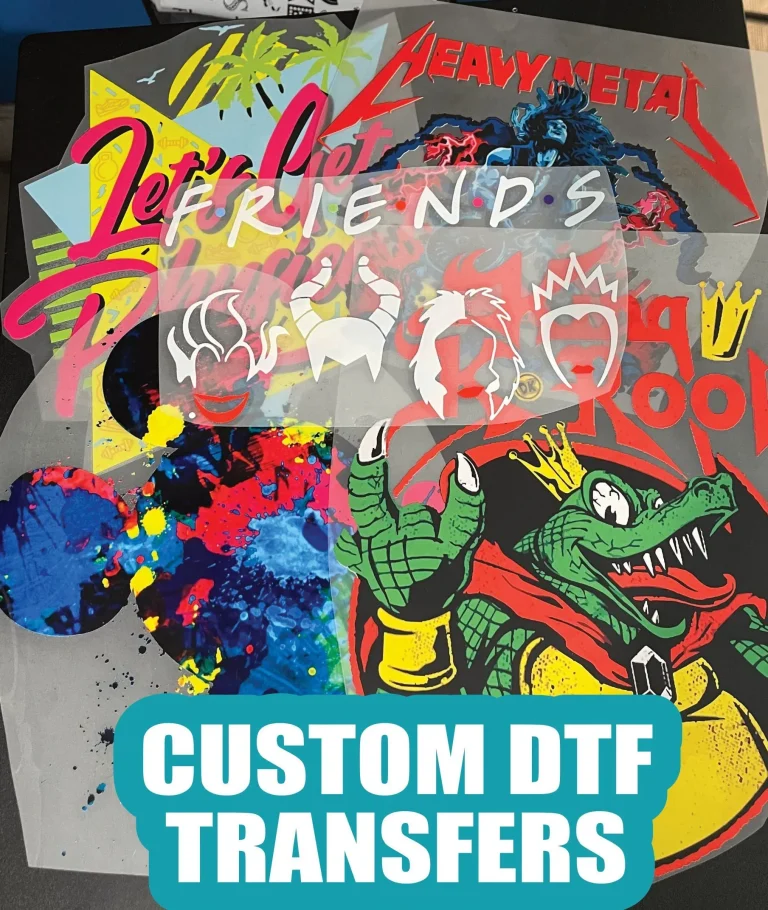

DTF Transfers Explained: Understanding DTF transfer methods and a beginner’s guide to applying designs

DTF transfers are created by printing a design onto a special film, applying an adhesive powder, curing it, and then transferring the image onto fabric using a heat press. This approach aligns with the core concept of DTF transfer methods, which share the same foundational steps while allowing for brand-specific tweaks. For anyone just starting out, DTF transfers offer vibrant color, fine detail, and a relatively straightforward workflow compared to some other decoration techniques. This section serves as a concise, beginner-friendly overview to help you grasp the basics of how the process works and why many crafters choose DTF for apparel projects.

To begin confidently, you’ll need to understand the practical workflow that underpins every successful transfer. The idea of “how to apply DTF prints” sits at the center of this process: prepare the design, print onto the DTF film, apply and cure the adhesive powder, pre-press the substrate, align the film, and complete the transfer with the heat press. Emphasizing consistency—especially temperature control and timing—helps you build a reliable routine that scales from a single item to small batches, reinforcing your position in the beginners guide to DTF transfers.

DTF Printing Tutorial and Practical Foundations for Beginners

A DTF printing tutorial walks you through preparing artwork, choosing film and powders, and executing the print-and-transfer sequence with clarity. It highlights essential steps like color management, choosing between mirrored versus non-mirrored outputs, and performing test prints to verify color accuracy and alignment. This foundational guidance aligns with the broader topic of DTF transfer methods and equips you with the knowledge to begin experimenting with different designs and substrates.

With the basics in place, you can move from theory to practice by following a repeatable, descriptive workflow: design prep, printing onto the DTF film, powder coating and curing, pre-pressing the fabric, and performing the transfer with consistent heat and timing. By documenting settings and results for each project, you’ll build a dependable routine that supports ongoing experimentation and improvement, a key part of any solid beginners guide to DTF transfers.

Optimizing Results: The Role of Heat Press Settings in DTF Transfers

While mastering DTF transfer methods is important, achieving consistent results hinges on precise heat press settings. The strength of a heat press lies in delivering uniform pressure and stable temperature, which directly affects adhesion, color vibrancy, and hand feel. Understanding how to manage these variables—especially when working with different fabrics or powder formulations—helps you avoid common issues and produces dependable outcomes across projects.

The recommended range of heat press settings for DTF transfers often centers around temperatures in the 160–170°C (320–338°F) zone with pressing times typically in the 8–12 second window. However, real-world results vary with substrate type, ink density, and powder formulation. By starting with these guidelines and then adjusting based on swatch tests, you’ll refine your technique and develop a precise, repeatable process that ensures quality in every transfer.

Frequently Asked Questions

What are the key DTF transfer methods and how to apply DTF prints, as described in a DTF printing tutorial?

DTF transfers involve printing on film, applying adhesive powder, curing, and transferring with a heat press. For a beginner-friendly workflow, start with a high‑resolution design, print onto DTF film using the recommended settings, and cure the powder-coated film. Pre‑press the substrate for 2–5 seconds, then align the transfer and press at about 160–170°C (320–338°F) for 8–12 seconds with firm, even pressure. After pressing, perform a quick hot or cool peel per product guidelines and allow a short post‑press cure. Use test swatches and keep equipment clean to maintain consistency across batches.

What should a beginners guide to DTF transfers cover to ensure consistent results, including heat press settings for DTF?

A good beginners guide to DTF transfers should cover selecting compatible components (DTF printer, film, adhesive powder, and a heat press), preparing designs, and a repeatable workflow: pre-press, the correct heat-press temperature and time, appropriate pressure, peel method, and post‑press curing. Emphasize calibration, safety, and testing on fabric samples (cotton, blends, polyester) to understand how different materials respond. Document settings for each batch to build a reliable process, keep equipment clean, and adjust for fabric variations to achieve consistent, durable transfers.

| Topic | Key Points | Practical Tips / Notes |

|---|---|---|

| DTF Transfers Overview | Direct-to-film printing; vibrant color, soft hand feel; generally simpler workflow than some methods; works on cotton, polyester, blends (and some leather/synthetics); results are durable and highly detailed. | Great for quick customization and mixed-media projects; ensure compatible inks/films and a suitable heat press. |

| Tools, Materials & Safety | DTF printer + inks; DTF film or PET film; adhesive powder; curing equipment; heat press with accurate temp control; protective film or release paper; suitable substrates; design software; safety: heat-resistant gloves, ventilation, follow temp/time guidelines; regularly calibrate the heat press. | Keep equipment clean; follow manufacturer guidelines; glove up when handling hot films; ensure good ventilation. |

| Step-by-Step Overview | Step 1: Prepare Design; Step 2: Print onto DTF film; Step 3: Apply adhesive powder and cure; Step 4: Pre-Press Substrate; Step 5: Align & Transfer; Step 6: Post-Press Curing & Finishing. | Mirror images where required; verify print settings; test dry run; ensure printed film dries completely; use test swatches to validate color and alignment. |

| Transfer Parameters & Post-Processing | Common temp range: 160–170°C (320–338°F); typical press time: 8–12 seconds; cooldown and potential second layers if needed; post-press curing helps final adhesion; assess hand feel and adjust pressure/time for best results. | Pre-press needed to remove moisture; use medium to firm pressure; align precisely; test peel type (hot/cool) per product guidelines. |

| Troubleshooting & Quality Control | Ghosting, white edge halos, stiffness, color shift; issues often tied to heat transfer, powder adhesion, or misalignment. | Revisit pre-press duration, ensure complete curing, re-check color management and printer calibration; use fresh powders/films. |

| Best Practices & Quick Guide | Choose compatible film and powder; balance print path/orientation; test on various substrates; record settings and outcomes; consider substrate versatility (cotton, blends, polyester); continue hands-on practice for consistency. | Maintain a log of trials; start with small batches; invest in quality powders/films; test different fabrics to optimize adhesion and color. |

| DTF Transfer Methods & Substrates | Understand multiple methods and how they affect adhesion and finish; DTF works on numerous fabrics, but some synthetics or leather may need adjustments. | Always test on target material; adjust curing times and temperatures for synthetics. |

Summary

HTML table created to outline the key points of the base content on DTF Transfers, including an overview, required tools, step-by-step workflow, transfer parameters, troubleshooting tips, and best practices. The table condenses the comprehensive guide into actionable bullets for quick reference.