DTF supplies are the backbone of modern garment customization, driving accessible, high-quality transfers for small businesses and hobbyists. Direct-to-Film printing has emerged as a versatile, cost-effective method for vibrant designs on textiles, and choosing the right DTF printer setup is essential. A well-curated set of DTF film and ink, adhesive powder, and curing equipment can dramatically improve print quality and durability. Understanding the DTF transfer process and matching supplies to your fabrics helps ensure soft hand-feel prints and reliable adhesion. From startup shops to hobby studios, laying a strong foundation in DTF supplies sets the stage for scalable, repeatable results.

In other words, the components used for Direct-to-Film projects—transfer media, printing inks, and heat-activation tools—form the core of a reliable workflow. These materials, when paired with appropriate film quality, powder adhesion, and a calibrated heat press, influence color vibrancy and wash durability. By exploring the ecosystem of film, inks, and powders, designers can optimize color management and achieve consistent results across fabrics. Successful DTF projects hinge on compatible equipment and thoughtful setup, from printer selection to curing practices. Looking ahead, optimizing the broader suite of transfer media and workflow tools empowers small shops to scale with confidence.

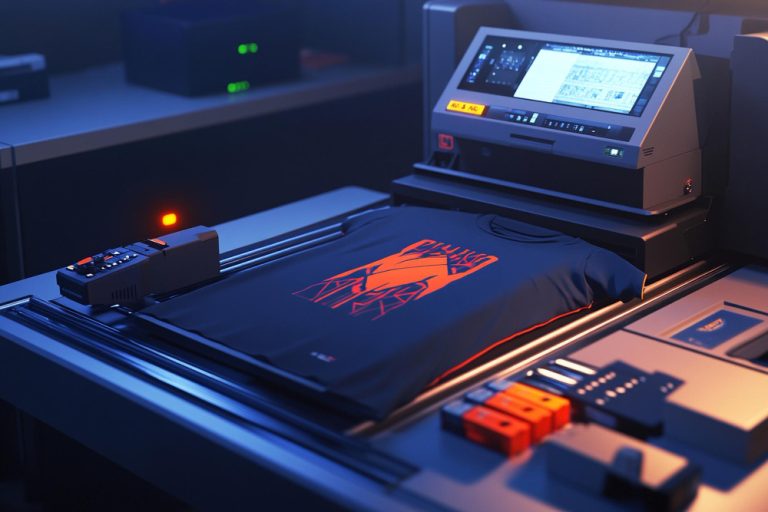

Choosing the Right DTF Supplies for a Smooth Direct-to-Film Printing Workflow

In Direct-to-Film printing, the overall quality and reliability hinge on selecting compatible DTF supplies. Start with a coordinated set of components that work together—from the printer and inks to the film and adhesive powder. Ensuring your DTF supplies are designed for your specific workflow minimizes color misalignment, reduces waste, and supports consistent production. Consider how your DTF printer setup integrates with the films, powders, and curing equipment to establish a solid foundation for every print.

A practical approach to choosing DTF film and ink, along with powders, is to test combinations before committing to large runs. Look for film thickness and surface finish that suit your artwork and fabric types, and verify that the inks deliver stable color and opacity on the intended substrates. Evaluate powder characteristics for uniform coverage and clean release, and choose a curing method that complements your inks. By aligning film quality, ink chemistry, and powder performance, you can optimize the Direct-to-Film printing process and achieve sharper details, vibrant colors, and reliable adhesion across a range of fabrics.

Optimizing DTF Printer Setup and the DTF Transfer Process for High-Quality Transfers

A well-tuned DTF printer setup lays the groundwork for consistent results. Start with accurate alignment, proper printhead maintenance, and color-management practices that align with your workflows. Use ICC profiles and monitor calibration to ensure what you see on screen translates accurately to the final DTF film print. A thoughtful printer setup, paired with appropriate film and inks, helps minimize color drift and improves color fidelity during the Direct-to-Film printing stage.

Understanding the DTF transfer process and its finishing steps is essential for durable, wash-fast results. After printing, the adhesive powder must coat evenly and cure properly to maximize adhesion to fabrics. Mastering the transfer involves controlling heat, pressure, and timing on the heat press, as well as post-transfer handling to preserve color vibrancy and hand feel. Regular maintenance and thoughtful workflow adjustments—such as optimizing curing routines and keeping the work area organized—keep the process efficient and deliver consistent transfers across batches.

Frequently Asked Questions

What essential DTF supplies are needed for Direct-to-Film printing, and how do I choose the right DTF film and ink for my setup?

Essential DTF supplies for Direct-to-Film printing include a DTF printer with compatible inks, DTF film and ink, adhesive powder, a curing device, a heat press, and basic workspace tools plus maintenance items and PPE. When choosing DTF film and ink, select a film designed for Direct-to-Film printing with appropriate thickness and anti-static properties, and pigment-based inks compatible with your printer and the film to ensure color fidelity and wash durability. Also ensure proper DTF printer setup, including color calibration and routine maintenance, to achieve consistent transfers.

During the DTF transfer process, how do DTF supplies influence durability and color vibrancy, and what parts of the DTF printer setup matter most?

DTF supplies—high-quality film, ink, adhesive powder, and reliable curing and heat-press equipment—directly affect adhesion, hand feel, color vibrancy, and wash durability. For best results in the DTF transfer process, ensure uniform powder application and proper curing, correct transfer temperature, time, and pressure, and use a well-maintained printer with accurate color calibration as part of the DTF printer setup. Proper film handling, consistent environmental conditions, and routine maintenance also help maintain color accuracy and prevent defects.

| Aspect | Key Points | Notes |

|---|---|---|

| What is DTF printing and why supplies matter | Direct-to-Film prints designs on pigment inks on film; adhesive powder is applied and cured; the film is transferred to fabric with heat. The quality and compatibility of DTF supplies (printer, inks, film, powder, heat press) affect hand-feel, color, and adhesion. | Soft hand-feel, bright colors, and durable transfers when components work in harmony. |

| Core DTF supplies you’ll typically need | DTF printer and compatible inks; DTF film; DTF adhesive powder; curing equipment; heat press or conveyor; weeding tools; cleaning/maintenance; PPE and safety gear. | Represents end-to-end setup for reliable transfers. |

| Choosing the right DTF supplies | Film quality/compatibility; ink chemistry; powder characteristics; heat press compatibility; budget vs return. | Match components to workflow and target fabrics. |

| Practical setup: building a DTF workflow | Design and color profile; print on film; apply powder; cure; transfer; post-transfer finishing. | Provides a repeatable, scalable process. |

| Optimizing color and detail | Calibrate color settings; use ICC profiles and color management; manage ink saturation; account for fabric variability. | Aims for consistent color accuracy across fabrics. |

| Common challenges and fixes | Powder not sticking; ink bleeding after transfer; poor color on dark fabrics; peeling after washing. | Provide quick fixes like adjusting heat, curing, and powder distribution. |

| Maintenance and longevity | Regular printhead cleaning; printer calibration checks; inspect films; store inks/powders properly. | Prevents downtime and maintains quality. |

| Safety, compliance, and best practices | Ventilation; PPE; storage/disposal; workspace organization. | Follows safety and regulatory guidelines. |

Summary

DTF supplies are the backbone of a scalable, high-quality Direct-to-Film printing operation. By selecting compatible inks, films, powders, and heat-setting tools, you can achieve consistent color, strong adhesion, and durable transfers across a wide range of fabrics. Plan your setup around production goals, test thoroughly, and maintain equipment to preserve print quality over time. Whether you’re a hobbyist exploring personalized apparel or a small shop aiming to scale, mastering your DTF supplies and workflow will empower you to deliver top-notch designs with speed and reliability.