Texas DTF printing is transforming how Texas brands turn artwork into wearable color with speed and durability. This approach, a form of Direct-to-film printing, blends vivid digital color with transfers that endure washing and wear. If you’re an entrepreneur, designer, or printer exploring new options, it offers a practical path from concept to production. From file prep to film handling and pressing, the workflow adapts to different fabrics and design challenges. By emphasizing consistent results and clear care guidance, shops can scale with confidence.

In broader terms, this film-based transfer workflow combines digital artwork, pigment inks, and heat-activated adhesives to create color-accurate graphics on fabrics. For those evaluating DTF printing for t-shirts, emphasis sits on color fidelity, strong adhesion, and efficient workflows that support small-batch production. Following design guides helps teams achieve clean edges, smooth gradients, and consistent results across cottons and blends. Adopting best practices—such as selecting compatible films, maintaining calibrated presses, and providing care guidance—can boost durability and customer satisfaction. Used together, these LSI-informed terms and a structured workflow enable durable results suitable for growing product lines.

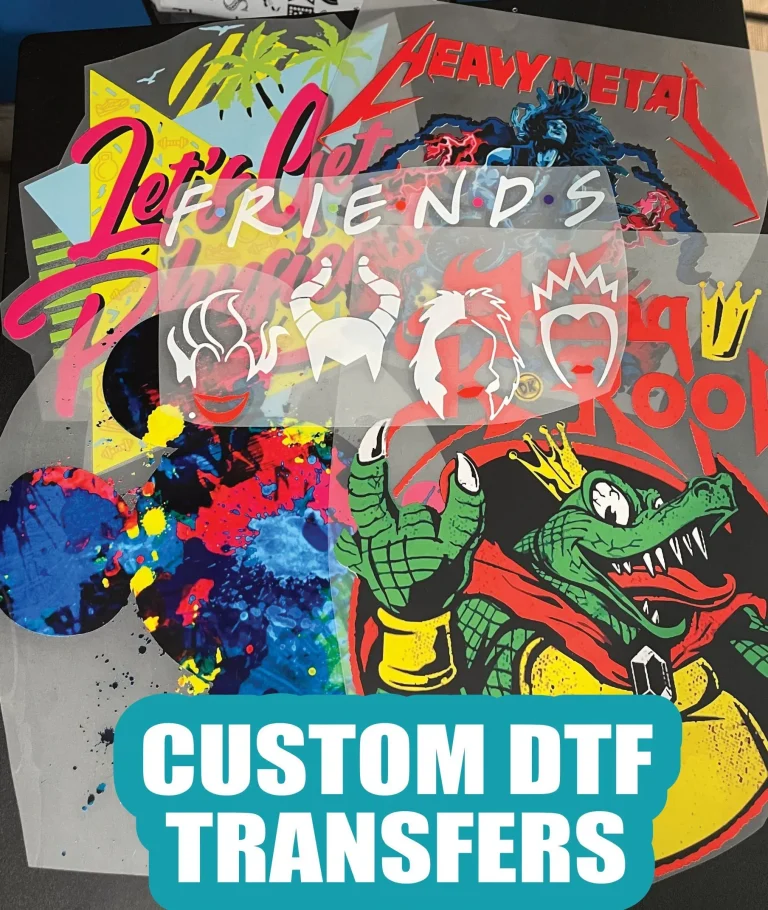

Texas DTF printing Best Practices: From Direct-to-Film Setup to Durable Transfers

Texas shops embracing Direct-to-film printing are discovering fast turnarounds and vibrant color on a wide range of fabrics. Direct-to-film printing enables high-resolution designs to be transferred with a powder adhesive, producing durable transfers that withstand repeated washings. Whether you’re building a local brand or offering custom tees, DTF printing for t-shirts in Texas blends digital precision with practical production workflows.

To maximize results, adopt Texas DTF printing best practices: calibrate your printer and color management workflow, choose inks and powders that pair well with your film, optimize curing temperatures and dwell times, and standardize a design-to-press routine that minimizes errors and waste. With a tight, repeatable process, you can deliver consistent color and adhesion across orders and fabrics.

DTF Design Guidelines for Vibrant Tees: Direct-to-Film Printing Considerations

When planning designs for Direct-to-film printing, follow DTF design guidelines to maximize clarity and color. Work in the target garment color space (often CMYK), export at 300 DPI or higher for sharp edges, and outline text to preserve typography after transfer. Also test gradients and overlays on fabric swatches to understand how ink and powder interactions may affect final appearance.

In addition, plan your press and peel strategy around the chosen inks and powders to ensure durable transfers. Document your cure temperatures, press times, and peel method (hot or cold) to achieve repeatable results, and provide clear care instructions to customers to protect the longevity of the print.

Frequently Asked Questions

What is Texas DTF printing, and how does it compare to other methods for DTF printing for t-shirts?

Texas DTF printing refers to direct-to-film printing using pigment inks on a release film, followed by heat pressing to bond the design to fabric. It delivers high color accuracy and detailed images, works across cotton and blends, and produces durable transfers for tees. Compared with screen printing and HTV, DTF printing for t-shirts typically offers faster setup, better color gradients, and lower minimum runs, making it a strong option for Texas shops and independent brands.

What are essential Texas DTF printing best practices to ensure durable transfers that withstand multiple washes?

Key Texas DTF printing best practices start with DTF design guidelines: design at 300 DPI, work in a CMYK color space, and plan safe margins. Use reliable adhesive powder, apply it evenly, and cure at the recommended temperature and time for your powder. Follow precise transfer press settings (time, temperature, pressure) for your garment type, and choose fabrics suited for DTF—primarily cotton and cotton blends. Finally, provide clear wash-and-care guidance to customers to preserve durable transfers.

| Topic | Key Points |

|---|---|

| What is DTF printing? | Direct-to-film printing prints designs on a transparent film, applies adhesive powder, cures, then transfers to fabric with heat and pressure; yields durable, vibrant transfers. |

| Why Texas DTF printing? | Popular for Texas brands and shops; supports local production with strong color fidelity and fabric versatility. |

| Workflow overview | From design to durable tees: design prep, film printing, powder application, curing, transfer, peeling, and quality checks. |

| Design and file preparation | Use vector logos, 300 DPI for raster images, CMYK workflow, include bleed and safe margins, and plan gradients/overlays for fabric. |

| Printing on the film | Print with compatible inks, ensure sharpness, calibrate color, and test with a color swatch before production. |

| Powder application and curing | Apply adhesive powder evenly, cure per vendor guidelines to ensure durability and avoid edge lifting. |

| Transfer to fabric | Align transfer on garment and press at recommended temperatures (e.g., 320–350°F / 160–177°C) for 15–25 seconds per ink/powder guidelines. |

| Peeling and finishing | Peel according to adhesive/ink (hot or cold); consider a brief post-press cure to boost wash durability. |

| Quality assurance and care | Inspect edge adhesion and color, and provide clear wash-and-care guidance to customers. |

| Choosing fabrics and materials | Cotton and blends perform well; polyester blends may need heat/time adjustments; account for weight, weave, and finish. |

| Equipment and supplies | Printer, DTF inks, release film, adhesive powder, curing device, heat press, PPE, and ventilation. |

| DTF design guidelines | Design at 300 DPI, use CMYK workflow, outline fonts, test gradients, and plan press/peel strategy for repeatability. |

| Texas-specific considerations | Rely on local suppliers, training programs, and community networks for support and best practices. |

| Common challenges and troubleshooting | Ghosting, edge lifting, peeling, cracking; address with calibration, curing, and compatible materials. |

| Getting started plan for Texas-based entrepreneurs | Start small, build a material library, invest in durable equipment, train staff, and market durability and color quality. |

Summary

Conclusion: Texas DTF printing offers a robust, flexible approach to creating vibrant, durable tees that withstand real-world wear and washing. By following the end-to-end workflow—from design to transfer—and paying careful attention to fabric choices, powders, cure times, and press settings, shops can achieve consistent, high-quality results that meet customer expectations and strengthen brand reputation. Whether you’re a Texas-based startup or an established shop expanding into direct-to-film printing, adopting best practices for DTF design and production will help you deliver long-lasting tees with vibrant color and reliable adhesion. Embracing this method can streamline production, shorten lead times, and open new opportunities for local brands across the state.