DTF gangsheet builder is transforming how shops plan and execute multi-design runs, delivering faster prepress, clearer cost control, and a competitive edge for printers who must meet tight timelines while maintaining color fidelity and durable shipping margins. In today’s competitive DTF printing efficiency landscape, smarter layout tools minimize waste and rework, helping studios fulfill orders faster while keeping quality intact, supporting scalable growth and long-term profitability. A well-designed gangsheet solution optimizes how designs are packed on a sheet, touching on gangsheet optimization, material savings, and consistent outputs across batches, with templates that repeatably reproduce results. By streamlining color management and reducing ink changes, it directly supports ink savings DTF and lowers run-time costs without compromising vibrancy or soft hand feel, even on high-volume campaigns. When comparing manual planning vs automation, the right DTF tool reduces bottlenecks, standardizes outcomes, and strengthens the overall DTF workflow across teams and machines, empowering operators to focus on creativity and precision.

An alternative way to describe this capability is as a DTF layout automation platform, a bulk sheet optimizer for transfer film printing, or a digital prepress tool that streamlines multi-design placement. From an SEO and search intent perspective, terms like automated layout generator, batch sheet planner, and sheet packing software help capture related queries that describe the same function. These tools support a scalable production line by reducing manual touchpoints, speeding up prepress, and stabilizing color management across runs. They enable a hybrid workflow where base placements are generated automatically and refined by operators for color tweaks or effects. In short, investing in this kind of automation translates to faster quotes, shorter lead times, and more consistent DTF outcomes across orders.

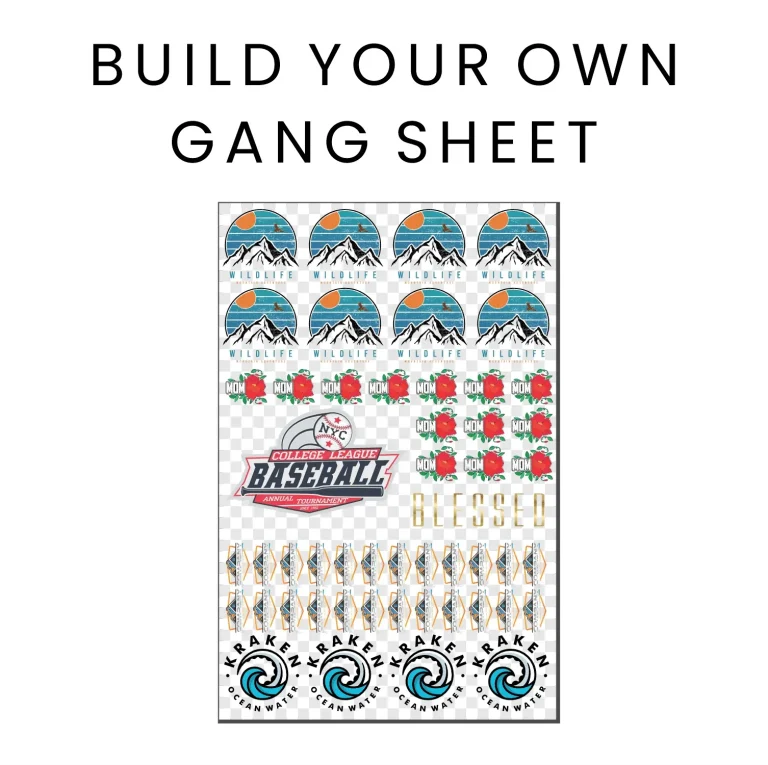

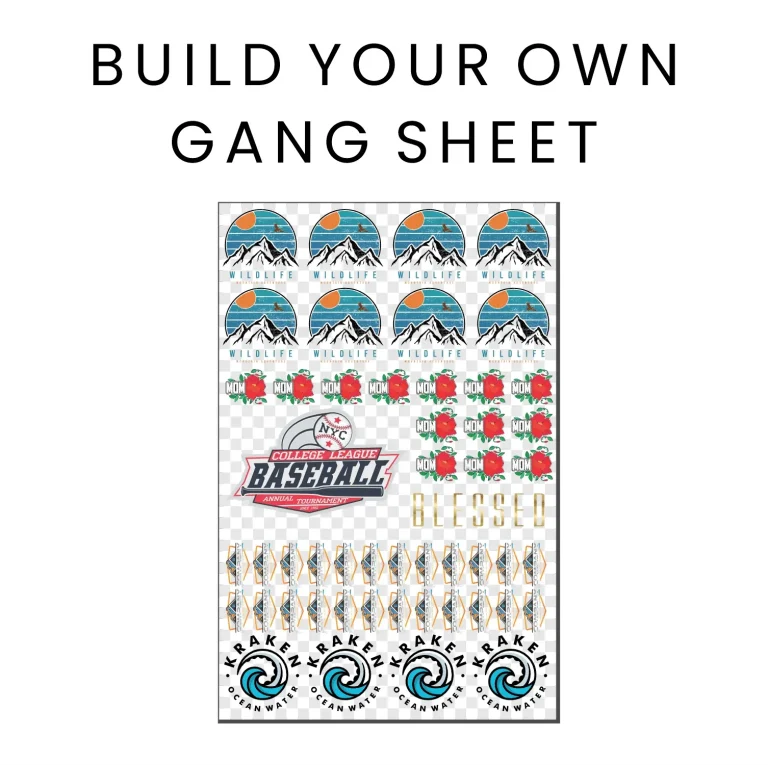

DTF gangsheet builder: maximize DTF printing efficiency with automated layouts and gangsheet optimization

A DTF gangsheet builder automates the layout process for multiple designs on a single sheet, dramatically cutting prepress time and reducing setup. This accelerates the DTF workflow by delivering faster transitions from art to print and by improving gangsheet optimization through tighter, more efficient packing of designs. Automated checks for color separations, bleed allowances, and file integrity help ensure consistent outputs and fewer misprints, which translates into tangible gains in DTF printing efficiency and overall throughput.

By aligning color passes, reducing unnecessary ink changes, and grouping similar designs on shared color channels, the builder minimizes ink loading fluctuations and waste. Standard templates support repeat orders with predictable results, speeding up production scheduling and invoicing. In practice, ink savings DTF become visible as you reduce blank space and media consumption across high-volume runs, while maintaining or improving print quality.

Manual planning vs automation in the DTF workflow: balancing control, speed, and cost

Manual planning vs automation is a central debate in DTF production. Manual planning gives designers and operators granular control over each element, but it often leads to a time drain, higher potential for misprints, and increased ink and media waste. When volumes rise, relying on manual planning can hurt DTF printing efficiency and disrupt the DTF workflow, making it harder to meet tight turnaround times.

A blended approach—base gang sheets generated by a DTF gangsheet builder with a human review for final tweaks—offers the best of both worlds. This balance preserves customization and artistic direction while preserving the gains in gangsheet optimization and ink savings DTF. It can speed up turnarounds, maintain quality across batches, and keep costs predictable as your operation scales.

Frequently Asked Questions

How does a DTF gangsheet builder improve DTF printing efficiency compared to manual planning?

A DTF gangsheet builder automates layout, optimizing placement, gaps, and color channels, which speeds up prepress and reduces misprints. It delivers consistent outputs and standard templates that streamline the DTF workflow. Compared with manual planning, automation typically cuts setup time, lowers ink loading changes, and reduces media waste, delivering noticeable ink savings over multiple jobs.

What is gangsheet optimization in a DTF gangsheet builder, and how does it impact ink savings DTF and the overall DTF workflow?

Gangsheet optimization is the automatic arrangement of multiple designs on a single sheet to maximize material usage and minimize waste. By optimizing layouts, color separations, and bleed, the DTF gangsheet builder reduces ink changes and wasted prints, driving ink savings DTF. This makes the DTF workflow faster, more predictable, and less dependent on manual planning, while still allowing targeted human tweaks for customization when needed.

| Aspect | Key Points | Impact / Why It Matters |

|---|---|---|

| What is a DTF gangsheet builder? | – Automates layout for multiple designs on one sheet; upload designs and specify print sizes and color separations. – Optimizes placement, gaps, and alignment; reduces waste. – Often handles color matching, bleed allowances, and file integrity checks to minimize misprints. |

Speeds setup, reduces waste, and lowers risk of misprints, improving overall throughput. |

| Benefits for DTF printing efficiency | – Faster setup and reduced re-work; operators move from art to print quicker. – Consistent outputs with automated layouts. – Material optimization: less blank space, fewer sheets used. – Standardization with templates. |

Higher throughput, lower material costs, and predictable quality across jobs. |

| Manual planning drawbacks | – Time drain from meticulous placement and checks. – Potential ink/media waste with suboptimal layouts. – Higher risk of human error and inconsistency across operators. |

Can work for small batches or highly customized runs but is costly and error-prone at scale. |

| Time savings | – Layout efficiency often cuts prepress time by 40-70% depending on designs per sheet. – Rework reduction through automated checks and templates. – Faster iteration cycles for different sizes and designs. |

Faster quotes, tighter production schedules, and improved customer satisfaction when scaled. |

| Ink savings: how it works | – Optimized color separations reduce unnecessary ink loading and transitions. – Fewer color changes by grouping designs on shared channels. – Reduced overprint errors; tighter bleed and margins prevent waste. |

Lower running costs with maintained print quality. |

| DTF workflow: automation vs hands-on planning | – Automation delivers reliable layouts quickly for scale. – Manual planning offers granular control for customization. – A blended approach uses automation for base layouts with human review for final tweaks. |

Supports a balanced, scalable production with consistent quality and flexibility. |

| Choosing the right approach | – Standardized, high-volume designs: automation typically saves time and ink. – Custom/art-forward work: manual planning remains valuable for final polish. – Hybrid workflows often yield best results: automated bases with human adjustments. |

Best fit depends on order mix, capacity, and desired balance of speed vs. customization. |

| Best practices for maximizing benefits | – Define templates and presets for color, bleed, and margins. – Calibrate color management across software and printer. – Run pilot tests to measure time and ink impact. – Integrate smoothly with RIP software and order management. – Train staff to unlock automation features. |

Consistent gains in time and ink savings when implemented with discipline. |

Summary

Table summarizes key points about the DTF gangsheet builder, its benefits over manual planning, and practical considerations for maximizing time and ink savings in DTF workflows.