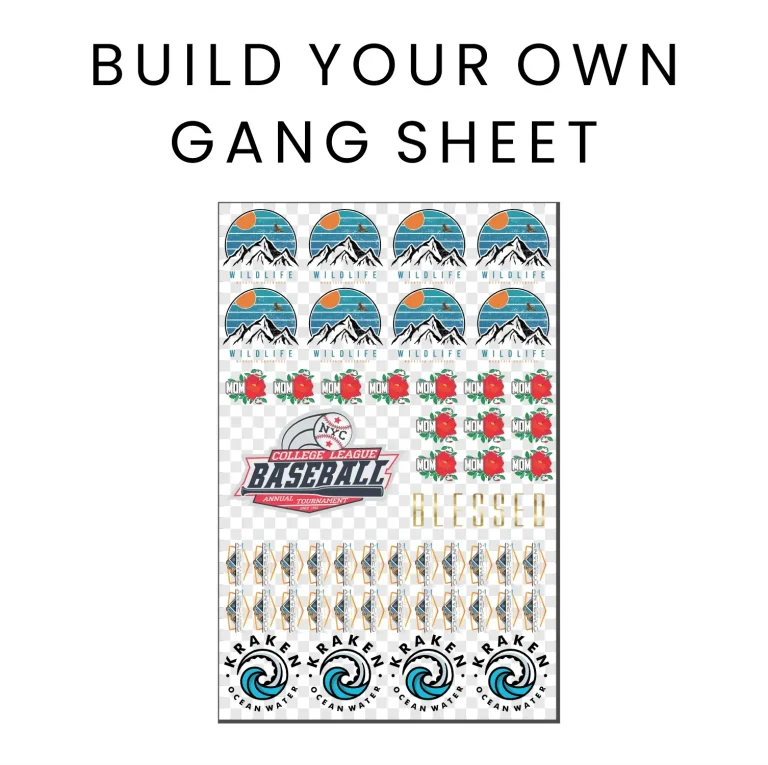

DTF gangsheet builder is transforming how small studios organize designs for apparel printing, letting you plan layouts with precision from the first draft. If you’ve ever juggled multiple designs, colorways, and turnover timelines, this tool helps align production, cut waste, and speed up orders in DTF printing workflows. By letting you place multiple designs on a single sheet, optimizing spacing through gangsheet optimization, and exporting production-ready files, it embodies a streamlined approach to direct-to-film printing. The result is less setup time, tighter color control, and scalable capabilities that support small teams pursuing growing catalogs and reliable small business printing solutions. With an emphasis on efficiency and accuracy, the DTF gangsheet builder integrates into existing workflows, making scaling custom designs more feasible than ever.

Viewed differently, the system functions as a multi-design sheet creator that batches transfer-ready graphics into a single run. From an LSI standpoint, this is a layout optimization tool for garment transfers, integrating artwork, color management, margins, and spacing into one cohesive workflow for DTF printing. It aligns with related concepts such as direct-to-film printing infrastructure, production automation, and scalable fulfillment for brands. Adopting this approach enables brands to grow their catalogs, test new colorways, and accelerate delivery without sacrificing quality. In short, the concept bridges design and production into a repeatable pipeline that supports growth, consistency, and competitive advantage.

DTF gangsheet builder: Accelerating Direct-to-Film Printing for Small Businesses

A DTF gangsheet builder consolidates multiple designs on a single sheet, making direct-to-film printing more efficient. By optimizing spacing, color blocks, and layout, you can reduce the number of print passes, speed up setup, and export production-ready files with minimal waste. For small teams working in DTF printing, this approach translates to faster turnarounds, consistent color management, and cleaner handoffs to printers and heat presses.

In practice, a gangsheet builder supports drag-and-drop design placement, sheet parameter settings, and auto-optimization that maximizes unit density without compromising print quality. It aligns with small business printing solutions by standardizing margins, bleed, and color references (Pantone or CMYK), which reduces surprises at the press. When you scale custom designs, templates and automated exports help you reproduce quality across orders while maintaining tight control over color fidelity and production data. Leveraging gangsheet optimization ensures efficient production runs and scalable workflows for growing catalogs.

Scaling Custom Designs with Gangsheet Optimization for Small Business Printing Solutions

Scaling custom designs becomes practical when you deploy gangsheet optimization to batch multiple artworks on a single sheet. This approach aligns with DTF printing workflows by balancing color blocks, preserving print quality on transfer films, and minimizing setup time per order, which is vital for small business printing solutions. By maximizing unit density on each gangsheet, you reduce ink usage and waste while speeding production and maintaining color fidelity across garments.

With standardized templates, centralized color libraries, and robust export options, small businesses can expand their catalog without sacrificing efficiency or accuracy. The result is a repeatable, scalable workflow that supports growth, quicker quotes, and reliable fulfillment across orders in the direct-to-film printing space. Embracing gangsheet optimization as part of a comprehensive DTF printing strategy enables scaling custom designs while preserving quality, consistency, and cost effectiveness for your brand.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it improve efficiency for small business printing solutions?

A DTF gangsheet builder is a software tool that lets you place multiple DTF designs on a single sheet, optimize spacing, manage color profiles, and export production-ready files for the printer and heat press. In direct-to-film printing, this approach reduces setup times, speeds production, and helps small businesses scale their custom designs without sacrificing quality.

How does gangsheet optimization support scaling custom designs in direct-to-film printing?

Gangsheet optimization automatically arranges designs on a sheet to maximize unit density while preserving color fidelity and margins. This standardizes layouts, reduces material waste and ink usage, speeds turnarounds, and creates repeatable workflows—ideal for small business printing solutions looking to grow with consistent quality across orders.

| Aspect | Key Points |

|---|---|

| What is a DTF gangsheet builder? | Designed to place multiple DTF designs on a single sheet, optimize spacing, manage color profiles, and export production-ready files with minimal waste. Consolidates designs into a single production pass, reducing setup times and enabling small teams to scale while maintaining quality. |

| Why it matters for small businesses | Efficiency, Consistency, Waste reduction, Scalable workflow, Clear production handoffs. |

| How it works | Import or create designs; set sheet parameters (size, margins, bleed, safe zones); arrange designs with auto or manual layout; color and print preparation; export production-ready files. |

| Step-by-step workflow | 1) Define a design bundle: gather designs, colorways, target garments; 2) Prepare artwork: normalize formats; 3) Create gangsheet layout: set sheet size, margins, bleeds; 4) Optimize colors/print data; 5) Validate/proof; 6) Produce/ship; 7) Review/iterate. |

| Real-world benefits | Increased output per hour; Lower material and ink waste; Faster turnaround; Greater catalog flexibility; Consistent quality across orders. |

| Best practices for color management and file export | Use a color-managed workflow; Export high-resolution PDFs/PNGs; Maintain standardized naming; Document processes for repeatability. |

| Common pitfalls to avoid | Overcrowded layouts; Inconsistent color references; Garment variability; Incomplete exports. |

| ROI case (simple scenario) | Example: three designs on a 12×18 sheet producing 20 units per batch; reduced setup time and ink usage yield improved margins and faster delivery over a month. |

Summary

DTF gangsheet builder is a strategic tool for small businesses aiming to scale custom apparel production. By enabling efficient layout, consistent color management, and accelerated production, it helps brands expand their design catalogs while preserving quality. As demand for personalized apparel grows, the DTF gangsheet builder delivers speed, accuracy, and cost savings that are difficult to achieve with manual methods. Embracing the gangsheet approach in your DTF printing process can unlock new levels of efficiency, consistency, and competitive advantage for your small business.