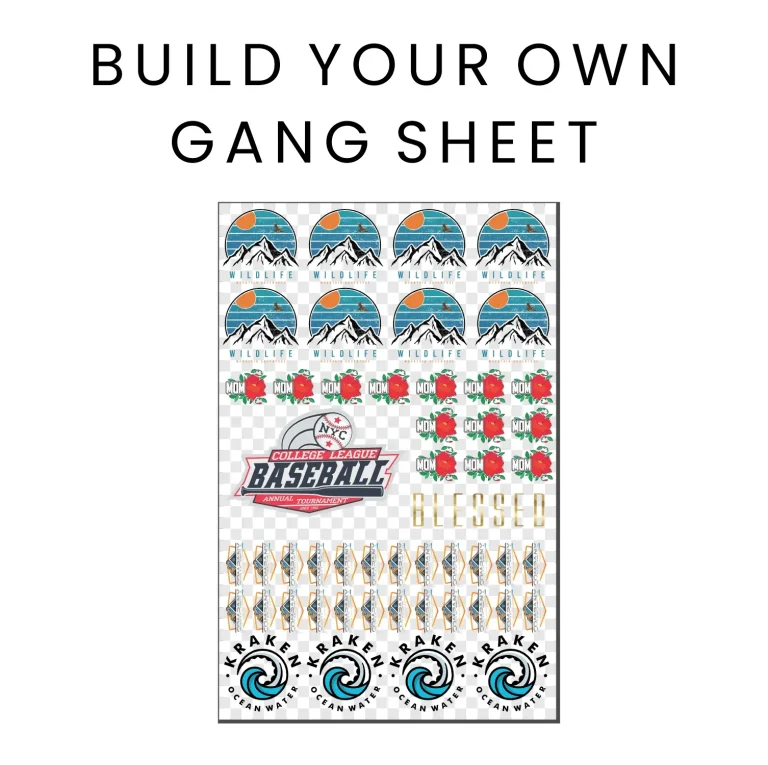

DTF Gangsheet Builder is transforming how studios plan and execute transfers. This versatile tool lets you pack multiple designs onto a single sheet, optimize ink usage, and streamline production, aligning with DTF printing and the gangsheet layout. From artwork to output, it supports a repeatable workflow that preserves margins, bleeds, and alignment, reducing setup time and waste. Whether you’re refining heat press settings or optimizing overall throughput, the Builder guides you toward reliable results. By following DTF transfer guidelines and robust DTF color management, you can deliver durable, vibrant transfers that meet client expectations.

From a broader perspective, this system functions as a sheet-based planning hub that coordinates multiple designs to share space without sacrificing detail. Think of it as a layout engine that synchronizes a grid, margins, and bleed, producing a single printable surface that can be split into many transfers. This approach emphasizes color fidelity, consistent alignment, and export-ready assets, aligning with a scalable production pipeline for apparel printing. In practical terms, it helps studios and shops translate complex artwork into repeatable, error‑resistant workflows that translate from screen to fabric.

DTF Gangsheet Builder: Maximizing Efficiency in DTF Printing and Gangsheet Layout

Leverage the DTF Gangsheet Builder to turn a collection of designs into a single, well-organized gangsheet. This approach aligns with the DTF printing workflow by consolidating multiple transfers into one print run, reducing ink consumption and minimizing setup time on the printer and heat press. By combining artwork strategically, you improve throughput while preserving fidelity, ensuring color blocks and details remain crisp across all designs.

Key decisions in the gangsheet layout—such as resolution, margins, bleed, and alignment guides—directly influence print fidelity. Prepare artwork at high resolution (300 to 600 dpi for rasters) or use scalable vectors, and export with color data that your RIP can reproduce. A grid driven organization and consistent margins reduce misregistration and speed up cutting on the finished sheet, supporting a smoother DTF printing pipeline and faster heat press throughput.

Ensuring Color Precision and Consistent Transfers: DTF Color Management, DTF Transfer Guidelines, and Heat Press Settings

Color management is central to reliable transfers. Use consistent color spaces, soft proofing, and ICC profiles to keep hues aligned from screen to film to fabric, which is the core of DTF color management. When planning transfers, reference DTF transfer guidelines to ensure the film, powders, and curing times support uniform color reproduction across all designs on the sheet.

Pair color discipline with disciplined heat press settings and testing. Run color-targeted proofs, verify gradient handling to avoid banding, and adjust dithering as your RIP suggests. By integrating heat press settings, transfer preparation, and post-press checks into a standard workflow, you can maintain consistent adhesion, durability, and overall finish across batches.

Frequently Asked Questions

How does the DTF Gangsheet Builder optimize the DTF printing workflow with a precise gangsheet layout?

The DTF Gangsheet Builder lets you pack multiple designs onto a single sheet using a grid-based gangsheet layout, reducing setup time and ink usage in DTF printing. By enforcing consistent margins, bleed, and alignment guides, it speeds production and minimizes misregistration. It also supports DTF color management by helping preserve color intent from screen to film to fabric, ensuring reliable results when you follow standard DTF transfer guidelines and heat press settings.

What practical steps should I follow when using the DTF Gangsheet Builder to ensure reliable transfers and consistent results?

Start with high-quality artwork prepared for DTF: 300–600 dpi raster or scalable vectors, with fonts outlined. Place designs on a grid that matches your RIP, include bleed and safe zones, and label each design clearly. Export using lossless formats (TIFF/PNG) with the validated color profile, then run a test print to verify color accuracy and alignment. During heat pressing, follow your DTF transfer guidelines and heat press settings (temperature, time, pressure) for the garment and substrate, and perform post-press inspections to catch any misregistration, adhesion, or finish issues. Document results and refine your gangsheet layout for future runs.

| Key Point | Description |

|---|---|

| What is the DTF Gangsheet Builder? | A tool to pack multiple designs on one sheet, optimizing ink usage and streamlining production for DTF transfers. |

| Core goal | Turn From Artwork to Output into a practical, repeatable workflow that yields consistent, print-ready results. |

| Value and benefits | Improves efficiency, reduces waste, and elevates transfer quality for any shop size. |

| Key concepts | Resolution, color management, and alignment to prevent color drift, misregistration, or blur. |

| Artwork preparation | High-quality files; 300–600 dpi raster; embedded or high-res vectors; careful typography; soft proofing; color modes; bleed and safe zones. |

| Gangsheet layout design | Grid-driven organization, consistent margins and bleed, labeling, color swatches, and clean layer organization. |

| Color management & RIP | Choose proper color space (RGB); maintain color intent; use ICC profiles; soft proof; color targets; monitor ink limits and gradients. |

| Output & transfer settings | Export as lossless/high-quality rasters (TIFF/PNG); maintain color profiles; appropriate DPI; transfer films/powders; proper pre-press; heat press ranges 150–180°C/302–356°F; post-press checks. |

| Quality checks | Verify registration, monitor color deviations, check pixel integrity and edge sharpness, assess adhesion/durability, and confirm substrate compatibility. |

| Practical tips & case studies | Three scenarios illustrate gangsheet creation, color management targets, test prints, and fabric considerations. |

| Operational integration | Develop SOPs, train staff, document processes, and continuously refine for consistency and reduced human error. |

Summary

DTF Gangsheet Builder is a pivotal tool in modern DTF production, connecting artwork to finished garments by enabling multiple designs on a single sheet while optimizing ink usage and reducing setup times. By guiding careful artwork preparation, disciplined gangsheet layouts, consistent color management, and precise transfer settings, it yields reliable, print-ready results across small studios to larger shops. Embracing a documented SOP and ongoing optimization with the DTF Gangsheet Builder helps shops improve efficiency, minimize waste, and sustain high-quality transfers across batches and seasons.