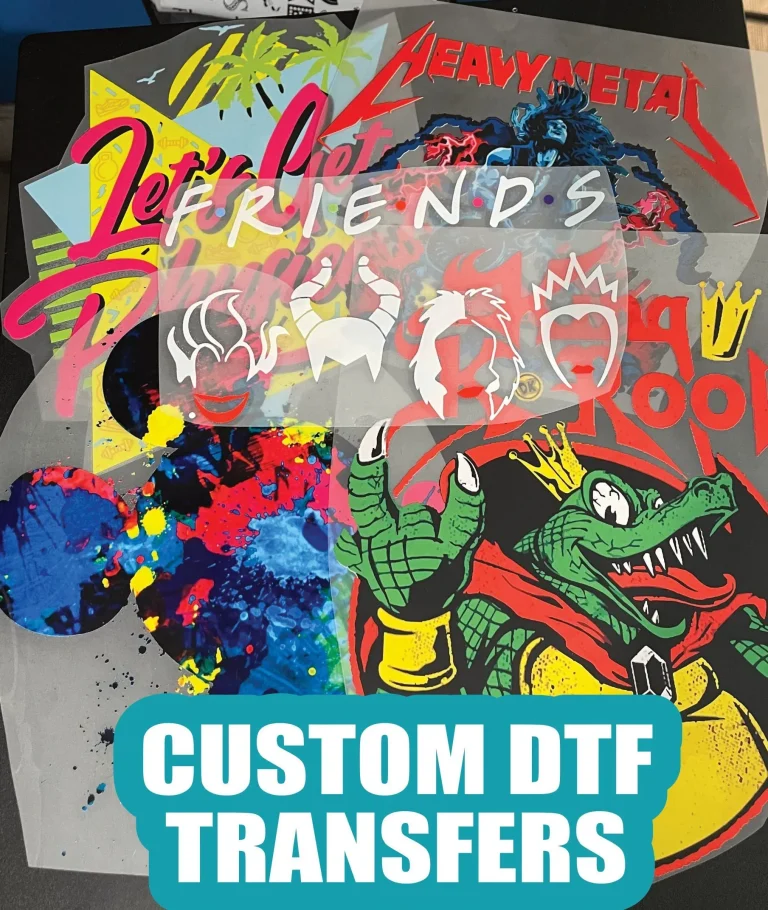

DTF transfers have revolutionized garment customization, offering designers and hobbyists a reliable path to vibrant, durable prints on textiles. As you explore heat-applied apparel decor, understanding DTF transfers is essential, and resources like DTF transfers explained break down must-have supplies and practical steps. With the right DTF powders and DTF transfer paper, this technique can achieve clear, vibrant results when paired with properly calibrated heat press settings for DTF. This guide also highlights durable fabric transfers as a key benefit, ensuring longevity through multiple washes. Whether upgrading from vinyl or trying direct-to-fabric printing, the process should feel approachable and scalable for projects of any size.

Viewed through the broader lens of direct-to-fabric printing, this method uses a printable film, white underbase, and adhesive powder to transfer designs onto garments. Other terms you might encounter—film-based transfer, print-on-film technique, or garment graphics on fabric—describe the same core workflow from a semantic perspective. The emphasis stays on color fidelity, fabric compatibility, and durable adhesion, making it a strong alternative to traditional methods. As you explore, consider how this technology scales from one-off tees to small runs, while remaining adaptable across textiles.

DTF Transfers Explained: Key Concepts, Materials, and Durability

DTF transfers explained describe a flexible, color-rich method where a design is printed on a specialized transfer film using water-based inks. After printing, a white underbase is laid down to boost color brightness, and a powder adhesive is applied before the print is cured and pressed onto fabric. The combination of transfer film, white ink layer, and adhesive powder creates a bond that travels with the fabric, enabling vibrant results on a wide range of textiles.

DTF transfer paper serves as the print substrate that carries the design from the printer to the garment, working in tandem with the transfer film. DTF powders are crucial for binding the print to the fabric during curing and transfer, contributing to a durable finish that resists cracking and peeling after multiple washes. When done correctly, these elements enable durable fabric transfers that maintain color depth and detail across different fabrics.

Optimizing Heat Press Settings for DTF: Achieving Vibrant, Durable Fabric Transfers

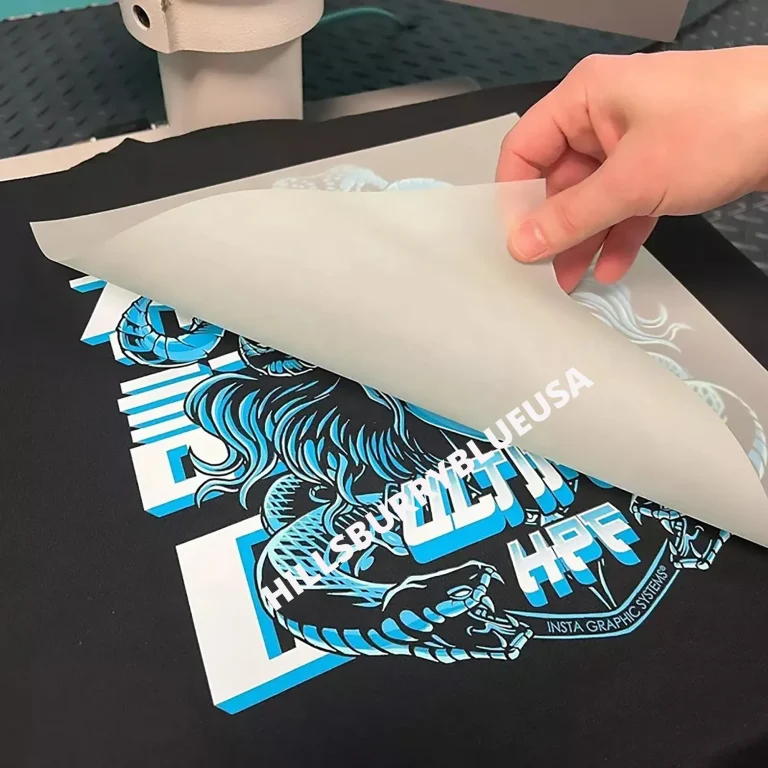

DTF transfers explained also hinges on the proper heat press settings for DTF. Typical starting ranges include 300°F to 320°F (150°C to 160°C) for 10 to 15 seconds, with medium to firm pressure. A brief pre-press of 2–5 seconds to remove moisture can help flatten the garment surface and improve adhesion, but always follow your film and powder manufacturer guidelines for best results.

Before committing to a production run, perform test prints on similar fabrics to fine-tune temperature, time, and pressure. The goal is consistent transfer quality across garments, while protecting fabric integrity. With accurate heat press settings for DTF and proper post-press care, you can achieve durable fabric transfers that maintain brightness, flexibility, and wash-fastness even after repeated wears.

Frequently Asked Questions

DTF transfers explained: how do DTF transfer paper and DTF powders create durable fabric transfers?

DTF transfers explained describes the process: designs are printed on transfer film, then coated with DTF powders (adhesive), cured, and pressed onto fabric with a heat press. The DTF transfer paper acts as the backing that carries the printed design to the garment, while the adhesive powder bonds the print during curing, enabling durable fabric transfers that resist cracking and peeling after washing. For best results, follow manufacturer guidelines for film, powder, and heat press settings, including a light pre-press, proper temperature around 300-320°F (150-160°C), time 10-15 seconds, and medium to firm pressure. After pressing, peel at the recommended stage and allow to cure. With careful curing and care, you’ll achieve vibrant, long-lasting prints.

What heat press settings for DTF should I use to ensure vibrant, durable fabric transfers across fabrics?

Start with common heat press settings for DTF: 300-320°F (150-160°C), 10-15 seconds, medium to firm pressure, and a brief pre-press. These settings for DTF can vary by fabric and film, so perform test prints on similar fabrics. Ensure you use DTF transfer paper as the backing and that the DTF powders are cured during the process, since proper curing is crucial for bond strength. Align the coated film with the transfer paper and apply even pressure for consistent adhesion. Following manufacturer guidelines helps you achieve durable fabric transfers with vibrant color and good wash resistance.

| Aspect | Key Points |

|---|---|

| Introduction to DTF transfers |

DTF transfers have revolutionized garment customization by enabling vibrant, durable prints on textiles. They provide a reliable route for heat-applied apparel decor and balance print fidelity with durability. This guide summarizes the must-have supplies, practical tips, and best practices to achieve clear, long-lasting results. Whether you’re upgrading from vinyl or curious about direct-to-fabric printing, this article walks you through what you need to know to get consistent, high-quality outcomes with DTF transfers. |

| What makes DTF transfers ideal for many projects? |

|

| Key terminology |

|

| Must-have supplies for successful DTF transfers |

|

| The printing, powdering, and curing workflow |

|

| A closer look at heat press settings for DTF transfers |

|

| Troubleshooting common issues in DTF transfers explained |

|

| Durability and care: making the most of DTF transfers |

|

| DTF transfers vs. other methods: a quick comparison |

|

Summary

DTF transfers offer a flexible, durable method for decorating fabrics, and this guide highlights why many creators rely on this technique for clear, long-lasting results. By selecting the right mix of supplies—DTF transfer paper, powders, a compatible printer, and a reliable heat press—and following proven steps for printing, powdering, curing, and pressing, you’ll unlock a versatile workflow for garments. With practice, you’ll refine your process, reduce errors, and push the boundaries of what’s possible with DTF transfers across a wide range of fabrics. Whether you’re producing a small batch of custom tees or exploring a new revenue stream, mastering the essential supplies and workflow will elevate your projects from good to great.