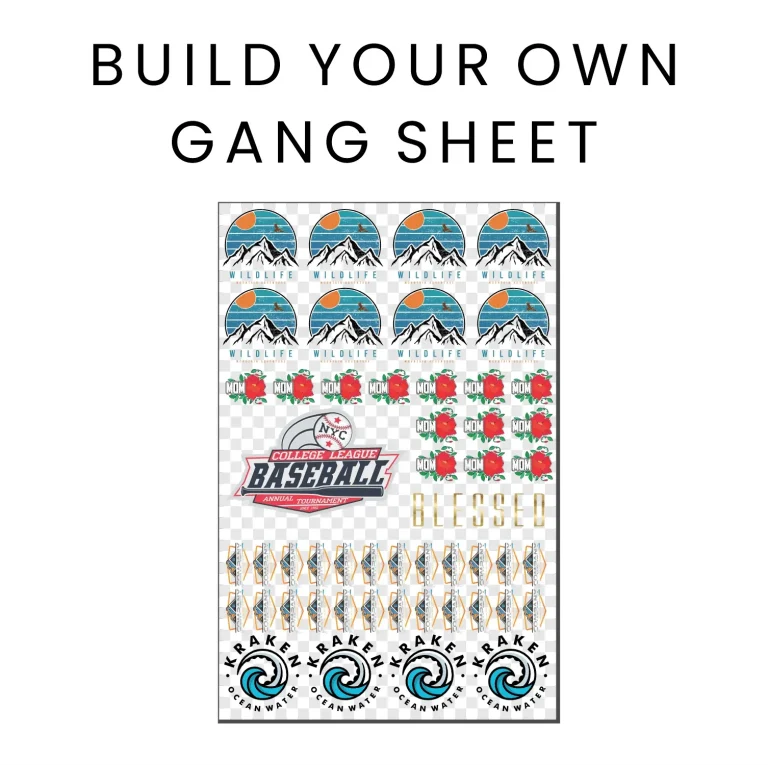

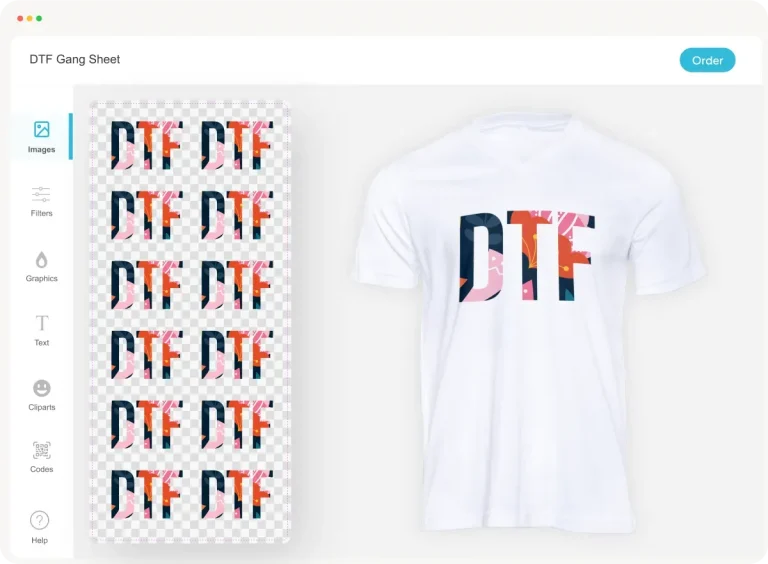

DTF gangsheet builder is reshaping how apparel and accessory shops prepare artwork for production, enabling teams to go from concept to print-ready files with fewer manual missteps. With DTF gangsheet automation workflows, designers upload multiple designs and let software optimize placement, bleed, and color margins, dramatically reducing setup time and the risk of human error. This approach boosts DTF printing efficiency by maximizing sheet real estate, aligning color profiles, and streamlining the handoff to production. Automation translates to faster turnarounds and lower costs, helping margins improve without sacrificing quality or flexibility for mixed-job batches. When you compare manual layout against automated workflows, the choice becomes a strategic lever for efficiency and predictable print outcomes.

Viewed through an alternative lens, this concept is a batch layout tool that clusters several designs onto a single print sheet to maximize material use. Rather than manually placing artworks, operators rely on intelligent layout software that standardizes margins, gaps, and color handling to maintain consistency. From a workflow perspective, it represents design-to-print automation that reduces repetitive tasks and accelerates the handoff to the press. In practical terms, shops report faster throughput, less waste, and more predictable costs as design mixes become the norm rather than the exception. In short, this approach aligns creative flexibility with lean production principles for scalable DTF operations.

DTF gangsheet automation: leveraging the DTF gangsheet builder for improved production efficiency and workflow optimization

DTF gangsheet automation streamlines the design-to-production cycle by automatically arranging multiple designs on a single gang sheet, reducing manual alignment and setup time. With a dedicated DTF gangsheet builder, operators can upload designs, set bleed, margins, and color profiles, and rely on intelligent layout to maximize sheet utilization. This creates a more consistent baseline across jobs, minimizes human error, and accelerates the transition from design to press, ultimately supporting a more efficient DTF workflow optimization.

Automation also enhances DTF printing efficiency by tightening color management handoffs and smoothing the handoff to RIPs. By standardizing settings and reducing repetitive tasks, shops can achieve faster turnarounds, fewer misprints, and a more predictable production rhythm. The result is stronger throughput, better resource planning, and a foundation for scalable growth that aligns with modern print-on-demand expectations.

Manual layout vs automated layout: driving cost savings and ROI in DTF production

Manual layout vs automated layout presents a clear trade-off between flexibility and efficiency. Manual layout offers granular control over each design but becomes labor-intensive and error-prone at high volumes, leading to longer lead times and higher labor costs. Automated layouts via a gangsheet builder optimize spacing, margins, and color management across batches, delivering faster setup and more consistent results, which directly feeds into DTF workflow optimization and overall production reliability.

When evaluating ROI, automation often delivers tangible DTF production cost savings through reduced labor, lower material waste, and higher throughput. A structured pilot can quantify time saved, waste reduction, and increased batch capacity, enabling a clearer path to payback. Over time, the improved efficiency translates into lower per-unit costs, improved delivery times, and a stronger competitive position, validating the switch from manual layout to automated layout as a smart investment.

Frequently Asked Questions

How does a DTF gangsheet builder impact DTF printing efficiency compared to manual layout?

Using a DTF gangsheet builder automates the layout step, placing multiple designs on a single sheet with optimized spacing and color management. Compared with manual layout vs automated layout, automation reduces setup time, improves consistency, and cuts waste, enhancing DTF printing efficiency. In typical shops, you can see 30–70% time savings per batch, enabling faster turnarounds and more predictable margins.

What production cost savings and ROI can you expect from DTF gangsheet automation as part of DTF workflow optimization?

DTF gangsheet automation delivers production cost savings by lowering labor hours spent on layout, reducing material waste, and boosting throughput within a broader DTF workflow optimization. Benefits include lower cost per order, improved sheet utilization, and fewer misprints. To estimate ROI, compare current layout hours and material costs to projected time savings (e.g., 30–70% per batch) and potential additional orders; many shops recoup the investment in a few months after piloting the solution. Plan for ongoing licenses, updates, and training during rollout.

| Topic | Key Points |

|---|---|

| What is a DTF gangsheet builder? |

|

| Why automation matters in DTF |

|

| DTF gangsheet automation vs manual layout: core differences |

|

| Time savings |

|

| Cost savings and ROI considerations |

|

| Practical implementation tips |

|

| Common misconceptions |

|

| Quality, consistency, and customer trust |

|

Summary

DTF gangsheet builder offers a clear path to faster, more consistent production and lower waste when handling multi-design batches. This automation-driven approach reduces manual setup time, improves layout accuracy, and optimizes material use, helping shops scale efficiently without sacrificing print quality. By piloting automation and measuring time, waste, and throughput, a shop can plan a phased rollout that aligns with production goals.