DTF transfers have emerged as a powerful option for customizing apparel, delivering vibrant colors across a wide range of fabrics. This technique relies on a precise DTF transfer process that starts with design, film, and adhesive powder, then moves to heat and pressure. As a form of DTF printing and fabric printing, it blends heat transfer technology with carefully formulated ink chemistry for DTF to achieve durable, wash-fast results. Understanding the science behind the method helps explain why outcomes vary with different fabrics, inks, and equipment, and why execution of each step matters for long-lasting prints. In this article, we explore the core concepts behind DTF transfers, from design to finish, and share practical tips for reliable results.

An alternative framing is direct-to-film technology, or film-based garment decoration, which describes the same technique from a different angle. In industry terms, this approach is often discussed as direct-to-film printing or transfer-on-film for textiles, highlighting its ability to deposit vibrant imagery without direct garment contact. The core idea remains: designs are printed onto a specialized film, coated with an adhesive powder, and activated with heat and pressure to bond to the fabric. From an LSI perspective, related concepts include ink formulation, substrate compatibility, and post-transfer care, which help explain performance across different materials. This broader vocabulary helps designers and printers align expectations and optimize outcomes across diverse fabric types.

DTF Transfer Process Demystified: From Design to Durable Fabric Prints

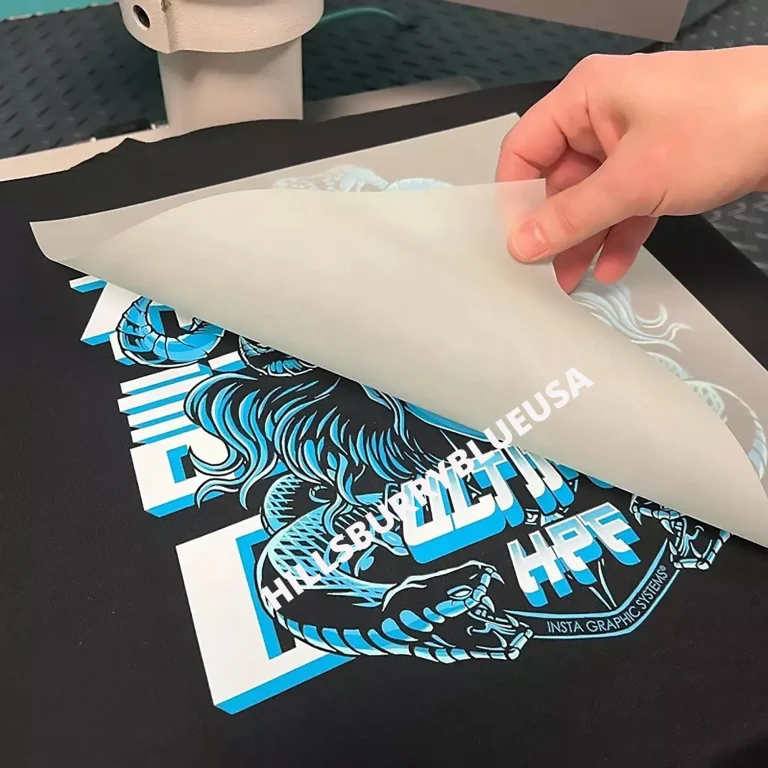

DTF transfer process is a sequence of steps that converts a digital design into a wearable graphic using heat transfer technology. At its core, the process combines film-based printing, adhesive powder, and controlled heat and pressure to create a durable bond with fabric. DTF printing uses pigment-based inks on a translucent PET film, where the white underlayer provides opacity and color reproduction on dark fabrics. Understanding the DTF transfer process helps printers diagnose variability across fabrics and inks and informs better choices in substrate and equipment.

From design to final garment, the workflow hinges on the interaction of ink chemistry for DTF with the film surface and the heat-activated adhesive. The result is a composite layer that sits on top of the fabric, not beneath it, and relies on surface energy, cure dynamics, and precise heat and dwell time to deliver clean edges, strong adhesion, and color fidelity. This description ties closely to fabric printing practices and to the broader frame of heat transfer technology that governs how textiles respond to press-time and temperature.

DTF Transfers: Optimizing Ink Chemistry, Film Choice, and Substrate for Consistent Results

DTF transfers demand careful optimization of ink chemistry for DTF along with the right film and adhesive combination. Pigment-based inks provide durability and color stability, while the white underlayer acts as a base for vibrant colors on dark fabrics. Selecting the right ink formulation, white saturation, and curing step is essential to prevent color bleed and to maintain edge sharpness during the transfer.

In addition, film choice, powder quality, and substrate compatibility shape performance across fabrics. Heat transfer technology relies on a film that releases cleanly, a thermal adhesive that bonds to fibers under precise temperature and pressure, and adequate dwell time to ensure full transfer without scorching. By aligning textile physics with ink chemistry for DTF and by testing across cotton, polyester, and blends, printers can improve consistency and durability.

Frequently Asked Questions

What is the DTF transfer process and how do ink chemistry and heat transfer technology influence the final print?

The DTF transfer process prints a design onto a PET film with water-based inks, applies an adhesive powder, cures, and then uses heat and pressure to bond the image to fabric. Ink chemistry for DTF—particularly pigment-based inks with a white underbase—controls opacity, colorfastness, and how well the ink adheres to the film and fabric. Heat transfer technology, including calibrated temperature, dwell time, and pressure, governs adhesive melting, ink behavior, and bond strength, impacting durability and wash performance.

How does DTF printing ensure durable fabric printing across different materials, and what roles do ink chemistry and transfer parameters play in edge fidelity?

DTF printing supports a wide range of fabrics by pairing the right film, ink system, and transfer settings with the fabric’s surface energy. Ink chemistry for DTF provides opacity and color stability, helping prints stay vibrant on dark and light fabrics. Transfer parameters—temperature, time, and pressure—along with uniform powder adhesion and careful peeling and cooling, determine edge fidelity, adhesion strength, and overall durability across cotton, polyester, and blends.

| Aspect | Key Points |

|---|---|

| What DTF transfers are | – Print a design onto a translucent PET film. – Apply heat-activated adhesive powder. – Use heat and pressure to transfer the image to fabric. – Compatible with a wide range of fabrics; vibrant color reproduction. |

| Core components | – Ink: water-based, pigment-based inks designed to work with film and the white underlayer. – Film: carrier for printing and delivery to fabric. – Adhesive powder: heats to bond ink to fabric. – Heat-press parameters: temperature, time, and pressure govern adhesion and finish. |

| DTF transfer process – steps |

|

| Physics – heat, time, and pressure | – Temperature controls melting and flow of adhesive powder and viscosity of ink. – Pressure ensures intimate contact among ink, adhesive, and fabric. – Time governs how fully adhesive melts and bonds; too little time reduces adhesion; too much can cause color bleeding or scorching. |

| Surface energy and fabric compatibility | – Surface energy affects adhesion; high-energy fabrics (cotton) promote stronger bonds. – Polyester and blends pose different challenges due to surface energy and weave; formulations address these differences. |

| Ink chemistry and the role of DTF printing inks | – Pigment-based inks with water as solvent offer colorfastness and opacity. – White underlayer is critical for vibrancy and preventing bleed-through. – Dye-based inks can be brighter on light fabrics but may be less durable on dark fabrics if not formulated. – White base affects color accuracy and edge sharpness. |

| Substrates, durability, and performance across fabrics | – Works on cotton, polyester, blends, and some synthetics; durability depends on wash resistance. – Natural vs synthetic fibers create different bonding environments; adhesive must bridge ink and fabric surface energy. – Properly tuned process yields durable, flexible bonds. |

| Common challenges and troubleshooting tips | – Color mismatch or dullness on dark fabrics; white ink yellowing or cracking; powder specks; adhesive residue; edge cracking after washing. – Solutions: calibrate color management with ICC profiles; ensure uniform white base; use fine, even powder; keep film clean; verify fabric compatibility; adjust dwell time and pressure; follow proper wash guidelines. |

| DTF transfers vs other printing methods | – DTF transfers offer versatility across fabrics, vibrant color, and easier handling of cotton blends and synthetics. – DTG excels on natural fibers but may require pretreatment for dark fabrics. – Sublimation works best on polyester with specific fabric bases. – Choice depends on project, fabric, budget, and required durability; understanding the science helps optimize results. |

| Practical tips for better results | – Choose the right film and printer system for your needs. – Manage color workflow with profiles; calibrate white base for range and opacity. – Control the environment (humidity and temperature). – Test on representative fabrics before large batches. – Maintain equipment: calibrate heat press and clean film residues. |

Summary

DTF transfers are a versatile method for decorating apparel, combining ink chemistry, film technology, adhesive science, and the physics of heat and pressure to produce durable, vibrant designs across many fabrics. By controlling each step—from design and printing to curing, transfer, and finishing—printers can optimize adhesion, color accuracy, and wash durability. The ongoing evolution of formulations and process controls will continue to push the performance and feel of DTF transfers, enabling designers and printers to expand the possibilities of fabric printing.