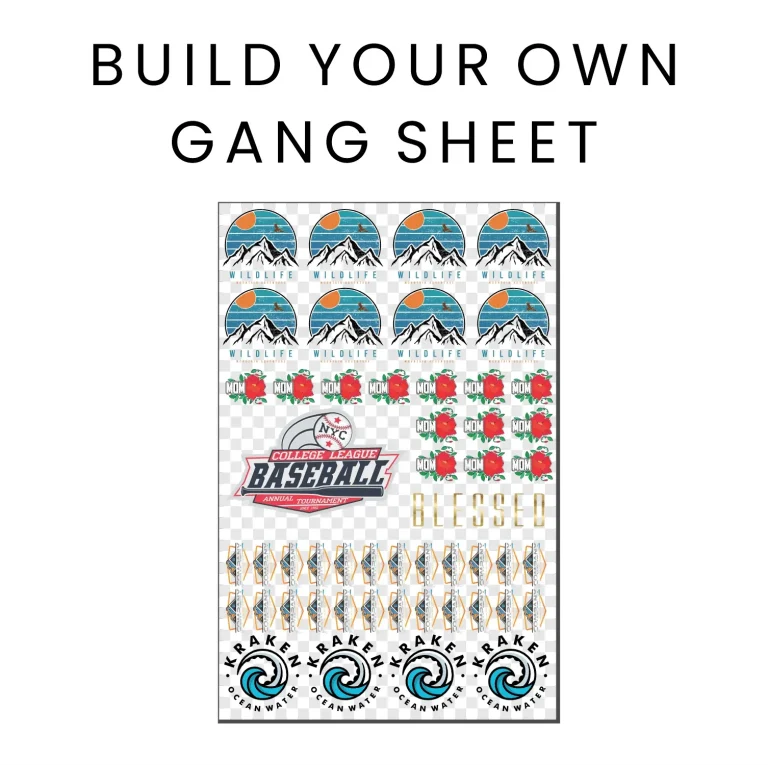

DTF Gangsheet Builder revolutionizes how you plan, layout, and execute transfers in Direct-to-Film printing, turning multiple designs into a single production-ready sheet. By consolidating designs on one gang sheet, it minimizes waste, speeds up production, and improves color consistency across runs. When evaluating tools for 2025, you will want to focus on DTF printing software features, a reliable gangsheet generator for DTF, and strong DTF workflow optimization. A good builder integrates with your RIP and printer settings to handle substrates, inks, and transfer processes with confidence. With export-ready formats and clear versioning, it becomes the central hub that keeps designs aligned from design file to finished transfer.

Viewed through a broader lens, this sheet-building platform serves as the central planner for turning discrete artwork into a single, production-ready layout. In practical terms, it acts as a design-to-production mapper that coordinates spacing, bleed, color profiles, and export formats to boost throughput and reduce waste. Industry discussions often reference DTF printing software features and DTF workflow optimization while also sharing hands-on tips like DTF gang sheet design tips. For teams aiming for 2025, the best DTF builder 2025 combines robust templates, version control, and seamless integration with RIPs, printers, and automation workflows.

DTF Gangsheet Builder: Boost Your DTF Printing Workflow and Efficiency

In the world of Direct-to-Film (DTF) printing, a DTF Gangsheet Builder acts as the nerve center that turns individual designs into a production-ready sheet. It consolidates multiple designs into a single printable gang sheet with precise spacing, margins, and bleed, helping you pack jobs efficiently and reduce material waste. By integrating with your RIP or printer settings, it ensures compatibility across substrates and transfer processes, while generating export-ready files that fit seamlessly into your workflow. This aligns with core DTF printing software features and emphasizes the usefulness of a robust gangsheet generator for DTF as part of a streamlined production pipeline.

Beyond layout, the real value comes from how a DTF Gangsheet Builder supports DTF workflow optimization. It reduces setup time, enables batch processing, and ensures consistent color management across sheets, which translates into faster throughput and fewer reprints. Operators can rely on trusted templates, versioning, and audit trails to maintain traceability and quality, aligning with the pursuit of best DTF builder 2025 outcomes. In practice, the tool becomes essential for teams that need reliable, scalable output without sacrificing color accuracy or design fidelity.

DTF gang sheet design tips for 2025: Templates, Color Management, and Throughput

Effective DTF gang sheet design starts with planning for real-world constraints like printer margins, substrate flexibility, and transfer temperatures. Establish defined padding between designs to prevent ink bleed and misalignment, and use color-aware layouts with embedded ICC profiles to preserve color integrity from screen to print. Test your layouts on representative substrates to validate color, texture, and adhesion, and keep critical elements such as text and logos away from edges to avoid clipping during trimming or pressing. Maintaining a reasonable sheet density helps preserve production speed and print accuracy.

Develop reusable templates for common product lines, document best practices, and implement a straightforward versioning system so changes can be rolled back if needed. This approach supports scalable, repeatable outputs as you grow toward 2025 targets and beyond. When combined with thoughtful DTF gang sheet design tips and a capable DTF gangsheet builder, you’ll achieve consistent results, easier QA, and improved throughput—key factors in establishing a lead position for the best DTF builder 2025.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it drive DTF workflow optimization?

A DTF Gangsheet Builder is a centralized tool that converts multiple designs into a single printable gang sheet with precise spacing, margins, and bleed. It accelerates production and improves DTF workflow optimization by automating layouts, enabling batch processing, and streamlining export to RIPs and printers. It also provides color management with ICC profiles and supports export formats (PDF/TIFF) compatible with your workflow, making it a true gangsheet generator for DTF. This aligns with core DTF printing software features.

What features should I prioritize to choose the best DTF builder for 2025?

Prioritize features that directly impact gang-sheet production and color fidelity. Look for flexible layout controls (rows/columns, rotation, drag-and-drop), auto tiling and templates, precise spacing and bleed, robust color management with ICC profiles, versatile export options and tight RIP/printer integration, batch processing and job queuing, a user-friendly interface, cloud/local libraries for design reuse, versioning/audit trails, and solid documentation and support. These align with DTF printing software features and support DTF workflow optimization. For the best DTF builder 2025, evaluate these areas in live demos and compare color accuracy across substrates.

| Aspect | Key Points |

|---|---|

| Overview | DTF Gangsheet Builder is a central tool in DTF printing that turns multiple designs into a single printable gang sheet, optimizing space, reducing waste, and speeding production. It supports layout planning, color management, and export-ready outputs, integrating with RIPs and printers for end-to-end workflow efficiency. |

| Core Benefits | Packages designs efficiently, minimizes material waste, lowers costs, and accelerates throughput by automating layout, spacing, and export steps while maintaining color fidelity. |

| Key Capabilities | Converts designs into a single printable sheet with precise spacing and margins; optimizes layout to maximize space; manages color and substrate compatibility; exports print-ready files (PDF/TIFF) and integrates with printer drivers. |

| Essential Features to Look For | – Flexible layout controls; – Auto tiling and templates; – Precision spacing and bleed; – Color management with ICC profiles; – Export options and RIP integration; – Batch processing and job queuing; – User-friendly UI; – Cloud/local libraries; – Versioning/audit trails; – Robust documentation and support. |

| Workflow Impact | Reduces setup time, ensures batch consistency, improves resource efficiency, enables faster iteration, and provides end-to-end traceability for audits and reprints. |

| Practical Design Tips | Plan within real-world constraints; use defined padding; maintain color integrity with embedded profiles; test on representative substrates; align text/logos; manage sheet density; create reusable templates; document practices; track versions; plan for scalability. |

| Choosing for 2025 | Look for real-time layout capabilities, reliable color management across substrates, smooth import/export with your RIP/printer, robust versioning/templates, batch job management, and a vendor roadmap that supports growth and ongoing support. |

| Conclusion (summary) | DTF Gangsheet Builder is a strategic asset for modern print operations, enabling efficient, accurate, and repeatable production. By focusing on core features, workflow optimization, and practical design tips, shops can select a solution that lowers waste, speeds up production, and scales with demand in 2025 and beyond. A strong DTF Gangsheet Builder integrates color management, template and version control, and seamless export, positioning your business to deliver consistent, high-quality transfers. |

Summary

HTML table above outlines the key points of the base content on DTF Gangsheet Builder, including overview, benefits, capabilities, essential features, workflow impact, design tips, and selection guidance for 2025, followed by a descriptive summary focused on SEO and practical value.