DTF transfers vs screen printing is a hot topic for brands shaping apparel decoration strategies today. Understanding how these two methods compare helps designers choose the right approach for T-shirts, hoodies, and bags for apparel printing methods. DTF transfers offer vibrant color fidelity and flexibility across fabrics, while screen printing shines in durability and cost efficiency at scale. This guide highlights performance factors, production considerations, and a cost and durability comparison to help you decide. By weighing setup, turnaround, and finish, you can align your choice with brand goals and customer expectations.

From a different angle, many shops think of this topic through digital textile transfers and classic silk-screen processes, both viable garment decoration options. When evaluating these modern and traditional techniques, consider how digital-to-film prints differ from the manpower-driven screen method in setup, speed, and material compatibility. The broader category, apparel printing methods, encompasses digital transfers, silkscreen, dye-sublimation, and other finishing options that affect texture and wash durability. Designers often weigh the cost implications and durability across fabrics, noting that each approach has its own niche in a production workflow. In short, a well-rounded decision blends the benefits of fast, high-detail digital processes with the dependable, scalable results of established screen methods.

DTF transfers vs screen printing: Choosing the best apparel printing method

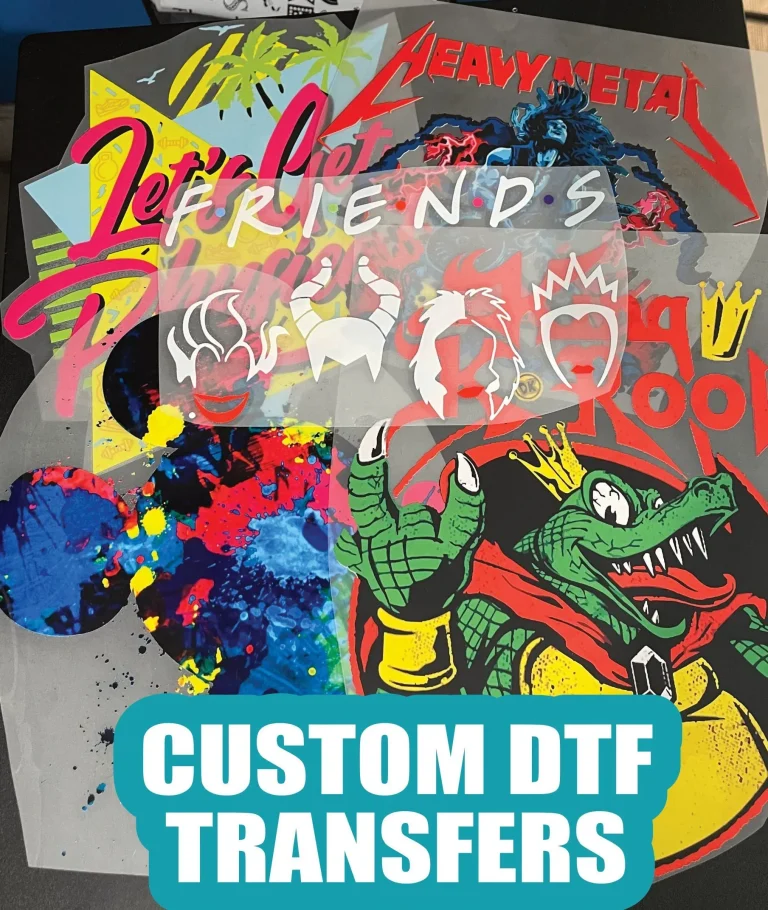

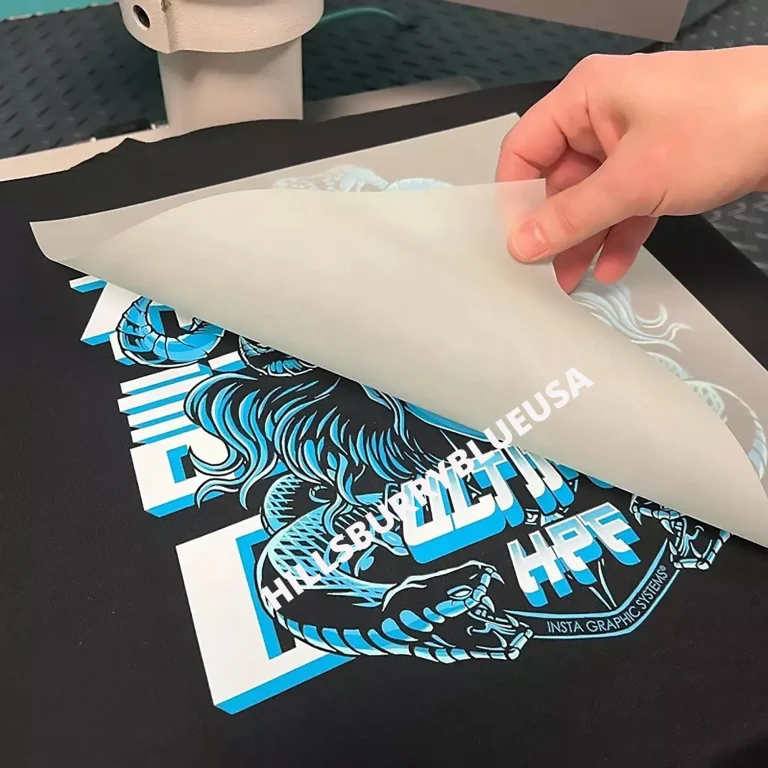

DTF transfers and screen printing are two cornerstone apparel printing methods used by brands, print-on-demand shops, and DIY crafters. DTF transfers involve printing onto a special film, applying adhesive powder, curing, and then transferring the design with a heat press. This method enables vibrant, full-color designs on a wide range of fabrics, including cotton, polyester, blends, and some dark fabrics with a white underbase. The flexibility and color capability make DTF appealing for complex artwork and small runs.

Screen printing uses mesh screens and ink passes to build your design, typically excelling in high-volume production with consistent color. When evaluating apparel printing methods, consider setup time, minimums, hand feel, wash durability, and total cost per unit. For many brands, the choice comes down to run size, design complexity, fabric variety, and time-to-market goals.

Cost and Durability Comparison: DTF vs Screen Printing

Cost considerations vary with run size and design complexity. DTF transfers typically have lower setup costs for small runs and custom orders, since you don’t pay upfront for multiple screens. Turnaround can be faster for rapid prototyping, making DTF appealing for limited editions and on-demand programs.

Durability is another key factor. Screen-printed inks generally deliver strong wash durability on cotton and heavy fabrics, with a tactile, solid hand. DTF durability has improved with modern film and adhesive formulations, but performance can differ by material, adhesive quality, and aftercare. It is important to validate adhesion and wash performance on your specific fabric mix.

Fabric and Garment Compatibility: How DTF Transfers and Screen Printing Perform

DTF transfers offer broad fabric compatibility, including blends and synthetics, with good color fidelity and adhesion. Screen printing works best on natural fibers like cotton but can be adapted for blends with the right inks and curing settings. Both methods fit within the broader category of apparel printing methods for diverse product lines.

Testing across your fabric lineup is essential. DTF can maintain color across a wide variety of fabrics, but adhesion and wash performance should be verified on each material. For performance fabrics or unusual blends, you may need tailored formulations or post-treatment steps to ensure durability and color retention.

Setup, Turnaround, and Production Scale for DTF and Screen Printing

DTF requires printing on film, powdering, curing, and then heat transfer, while screen printing requires creating screens and running multiple press passes. For very small runs, the DTF workflow can speed up time to market due to fewer upfront setup steps. For large orders, screen printing can achieve higher throughput once the setup is complete.

Production scale also influences costs and consistency. Screen printing allows unit costs to drop with volume and color consistency to be tightly controlled across thousands of units. DTF remains flexible for varying designs and fabric types, but batch-to-batch consistency may depend on film quality and curing calibration.

Color Capabilities and Image Quality: Multi-Color Designs in DTF and Screen Printing

DTF transfers excel at color fidelity, gradients, and fine lines, making multi-color artwork and photos pop on apparel. The ability to reproduce photographic imagery with smooth transitions is a strong draw for designers working with complex artwork.

Screen printing can deliver bold, opaque colors with a tactile ink layer and high durability, especially on light fabrics. When designs require extreme detail or color depth, DTF’s ongoing improvements help, but screen printing remains competitive for large runs with simpler palettes and a strong hand feel.

Practical Decision Guide for Brands: When to Use DTF Transfers, When to Choose Screen Printing

For brands deciding between DTF transfers and screen printing, start by mapping design complexity, run size, and fabric mix to your goals. If you need fast prototyping, many colors, or prints on diverse fabrics, DTF transfers are a flexible option within the broader category of apparel printing methods.

If your priority is long-run cost efficiency, consistent color across thousands of units, and a proven durable hand on cotton, screen printing often becomes the better choice. In practice, many brands blend approaches: use DTF for small runs or complex imagery and reserve screen printing for bulk production of simpler designs. Always test with real samples to evaluate color, adhesion, and wash durability across your fabric portfolio.

Frequently Asked Questions

DTF transfers vs screen printing: how do these apparel printing methods compare on cost and durability for small-batch orders?

In a cost and durability comparison, DTF transfers typically have lower upfront setup costs and faster time-to-market for small-batch runs, making them ideal for personalized designs. Screen printing becomes more cost-efficient per unit as volume increases, but its setup can be heavier for multi-color designs. Durability varies by fabric and curing quality, with screen printing often delivering strong wash durability on cotton and DTF offering excellent durability when the adhesive and film are properly cured.

What is the cost and durability comparison between DTF transfers and screen printing when printing on a variety of fabrics in apparel printing methods?

DTF transfers provide versatile performance across a wide range of fabrics with lower initial setup for custom orders, lowering upfront costs. Screen printing can yield lower unit costs in large runs, especially for simple designs. Durability depends on material and process: screen printing is typically very durable on natural fibers, while DTF can match or exceed durability on many fabrics when properly cured.

When should brands choose DTF transfers vs screen printing for high-volume orders, considering the cost and durability aspects of apparel printing methods?

For high-volume orders, screen printing usually offers the best per-unit cost after the initial setup, making it the preferred choice for large runs. DTF transfers are better suited for flexible, low- to mid-volume production or designs with many colors and fabrics. Both methods can be highly durable with proper curing; testing is recommended to confirm results.

Can DTF vs screen printing handle complex multi-color designs, and how does this affect cost and durability in apparel printing methods?

DTF transfers handle complex multi-color designs with fewer color separations, which can reduce setup time and cost for detailed artwork. Screen printing can also reproduce multi-color designs but requires additional screens and more setup, increasing initial cost and lead times. In terms of durability, both methods can be durable with proper curing; color fidelity is often excellent for DTF and strong opacity for screen printing on appropriate fabrics.

Which method offers better wash durability and hand feel: DTF transfers or screen printing, within the cost and durability comparison framework of apparel printing methods?

DTF transfers often provide a softer hand feel due to the thin film and adhesive layer, which can be advantageous for comfort. Screen printing can feel thicker, especially on dark fabrics, but offers excellent wash durability when inks are properly cured. In a cost and durability comparison, the choice depends on design complexity, fabric type, and desired finish; testing samples is recommended.

What should you test when comparing DTF transfers and screen printing across fabrics in apparel printing methods to ensure color fidelity and adhesion?

Test on the fabrics you plan to offer (including blends and synthetics) to compare color fidelity and adhesion. Evaluate color accuracy, edge sharpness, and the fabric’s stretch or recovery, then check wash performance after curing. This practical testing helps validate which method—DTF transfers or screen printing—best meets your color goals and durability expectations.

| Topic | Summary |

|---|---|

| DTF transfers | What DTF transfers are: DTF stands for direct-to-film. A design is printed onto a special film, coated with adhesive powder, cured, and heat-transferred to fabric. This yields full-color, vibrant prints that work on cotton, polyester, blends, and some dark fabrics with a white underbase. DTF is popular for reproducing complex multi-color artwork with fine detail and smooth gradients, while avoiding large screen setups. |

| Screen printing | What screen printing is: Ink is pushed through mesh screens onto fabric; each color uses its own screen, and multiple passes build up the final design. Best for high-volume runs, cost-effective at scale, with strong color, durability, and a slightly thicker ink layer. |

| Key differences in practice |

|

| Cost and production scale |

|

| Quality, finish, and feel |

|

| Fabric and garment compatibility |

|

| Practical decision guide |

|

| Common myths and realities |

|

| Practical checklist |

|

Summary

DTF transfers vs screen printing is a topic many apparel brands consider when planning new lines, balancing design complexity, production volume, and fabric compatibility. There is no one-size-fits-all answer; the best choice depends on goals for color fidelity, hand feel, durability, turnaround time, and cost. The overview above explains how DTF transfers work, what screen printing delivers, and how each method influences texture, wash performance, and scalability. In practice, many brands use a blended approach—DTF for complex, multi-color designs or small runs, and screen printing for large-volume orders of simpler designs. By testing on representative fabrics and aligning your print strategy with your brand’s objectives, you can deliver apparel that looks great, feels right, and withstands regular wear and washing.