UV DTF printing is revolutionizing the world of custom apparel design, offering a powerful blend of quality and innovation that meets the demands of today’s fashion-forward consumers. This advanced printing technology utilizes ultraviolet light to cure inks directly onto films, enabling designers to achieve vibrant colors and intricate details with outstanding durability. As the apparel industry continues to evolve, UV printing technology stands out as a top choice among apparel printing methods, thanks to its efficiency and eco-friendly properties. Not only does it reduce production time significantly, but it also supports sustainability by minimizing the use of harmful chemicals. Brands eager to create personalized apparel that leaves a lasting impression are increasingly turning to UV DTF printing for its exceptional versatility and environmental advantages.

The emergence of UV DTF printing marks a significant shift in personalized garment production, showcasing a modern approach to custom textile decoration. Also known as ultraviolet Direct to Film technology, this sophisticated method ensures that the printing process is both rapid and precise, allowing for stunning results on a variety of fabric types. As manufacturers adapt to the growing consumer desire for individualized clothing options, this innovative printing solution meets those needs while promoting eco-friendly practices within the industry. By facilitating richer colors and cleaner designs, UV DTF can help brands maintain a competitive edge in the crowded custom apparel market. Shaping the future of apparel customization, this technology empowers designers and brands alike to push the boundaries of creativity and craftsmanship.

Understanding UV DTF Printing: The Future of Custom Apparel

UV DTF (Direct to Film) printing is rapidly gaining traction in the custom apparel design industry, thanks to its unique capabilities that set it apart from traditional apparel printing methods. The process uses ultraviolet light to cure inks, leading to prints that are not only striking in color depth but also incredibly durable. Unlike conventional printing methods that may lead to fading or peeling over time, UV DTF printing ensures that designs maintain their vibrancy, even after multiple washes. Its advanced technique allows for greater detail in artwork, making it a popular choice among designers looking to create intricate and personalized apparel.

As the market for custom apparel evolves, brands are increasingly looking for ways to differentiate themselves from competitors. UV DTF printing perfectly aligns with this need, offering a high-quality printing solution that resonates with consumers who prioritize durability and aesthetics. With its ability to print on various fabrics, including cotton and polyester blends, the possibilities for custom apparel designs are virtually limitless. Brands that invest in UV DTF technology can better cater to customer demands for unique, high-quality clothing, thus positioning themselves as leaders in the dynamic custom apparel market.

The Versatility of UV DTF Printing: Crafting Unique Designs

One of the hallmark features of UV DTF printing is its versatility, accommodating a wide range of fabrics and substrates. This flexibility is crucial for companies in the custom apparel design space, as it allows them to experiment with materials and create garments that appeal to diverse consumer tastes. From soft cotton t-shirts to sturdy polyester athletic wear, UV DTF printing can adapt to various fabric types without compromising print quality. This capability ensures that designers can bring their creative visions to life, producing unique apparel that speaks to individual styles and preferences.

In addition to fabric versatility, UV DTF printing offers an extensive color range and intricate detailing. Coupled with its ability to print on dark or colored fabrics without the need for a white underbase, this technology provides designers the freedom to unleash their creativity. As a result, the custom apparel market is witnessing a shift towards personalized designs that tell a story or reflect personal identities. Brands embracing this multi-faceted approach to design are finding success as they tap into consumer trends that emphasize individuality and self-expression.

Eco-Friendly Innovations in UV DTF Printing

As sustainability becomes a paramount concern in the fashion and apparel industry, UV DTF printing emerges as an eco-friendly alternative to traditional printing methods. This technology uses inks that emit significantly lower levels of volatile organic compounds (VOCs), making it a greener choice for brands seeking to minimize their environmental impact. The reduced environmental footprint of UV DTF printing allows apparel companies to showcase their commitment to sustainability, appealing to a more eco-conscious consumer base.

Moreover, the efficiency of UV DTF printing contributes to its sustainability credentials. The instant curing process reduces waste associated with traditional printing, where unoptimized methods often lead to ink spillage and overproduction. Brands adopting UV DTF printing are not only portraying themselves as environmentally friendly but are also streamlining their operations, saving time and resources. By investing in eco-friendly printing practices, companies can cultivate a positive brand image while meeting the growing consumer demands for sustainable fashion.

The Key Advantages of UV DTF Printing for Business

The advantages of UV DTF printing extend beyond just print quality; they also include significant efficiency and cost benefits. The rapid curing process allows businesses to handle more orders with shorter turnaround times, making it an ideal solution for small batch productions or customized orders. This efficiency is particularly useful in today’s fast-paced market, where consumer preferences can shift overnight, and brands must be agile in their responses.

Additionally, the longevity and durability of prints created using UV DTF technology contribute to a better return on investment for apparel companies. As the prints resist fading and damage from regular wear, customers find greater satisfaction in their purchases. Consequently, brands not only enhance customer loyalty but also build a reputation for quality that can drive sales growth. This competitive edge positions brands well in an increasingly crowded marketplace where customers are looking for unique and durable apparel options.

How UV DTF Printing Sparks Innovation in Custom Apparel

The introduction of UV DTF printing technology has sparked a wave of innovation in the custom apparel industry. As designers and brands experiment with this advanced method, they are uncovering new applications, techniques, and design possibilities. This innovation does not only improve the quality and style of the final product, but it also opens avenues for unique collaborations and limited-edition drops that can captivate consumer interest.

Furthermore, as brands embrace UV DTF printing technology, they are encouraged to think outside the box when it comes to design and customization. Trends like upcycling and personalized apparel soar as the technology supports more intricate detailing, allowing for the embedding of personal stories or brand values in everything from t-shirts to jackets. By harnessing the creativity enabled by UV DTF printing, companies can offer products that resonate deeply with consumers, making them feel seen and understood on a personal level.

The Future of Custom Apparel with UV DTF Printing

Looking towards the future, UV DTF printing is poised to revolutionize the custom apparel market even further. As technology continues to advance, we can expect improvements in speed, sustainability, and the overall quality of prints. New advancements may reduce costs and allow even smaller brands to access high-quality printing without compromising on their eco-friendly goals.

As more companies adopt UV DTF technology, the standards for custom apparel will likely evolve, leading to an industry-wide push for higher quality and more innovative products. This promising future means that brands, regardless of size, can leverage UV DTF printing technology to not just meet but exceed consumer expectations, paving the way for a new era of custom apparel design that prioritizes quality, sustainability, and personalization.

Frequently Asked Questions

What is UV DTF printing and how does it benefit custom apparel design?

UV DTF printing, or Direct to Film printing, is a cutting-edge technology that uses ultraviolet light to cure inks onto films for vibrant, durable prints on fabrics. It benefits custom apparel design by providing unmatched detail, color depth, and quick turnarounds, meeting the demands for quality and personalization in the fashion industry.

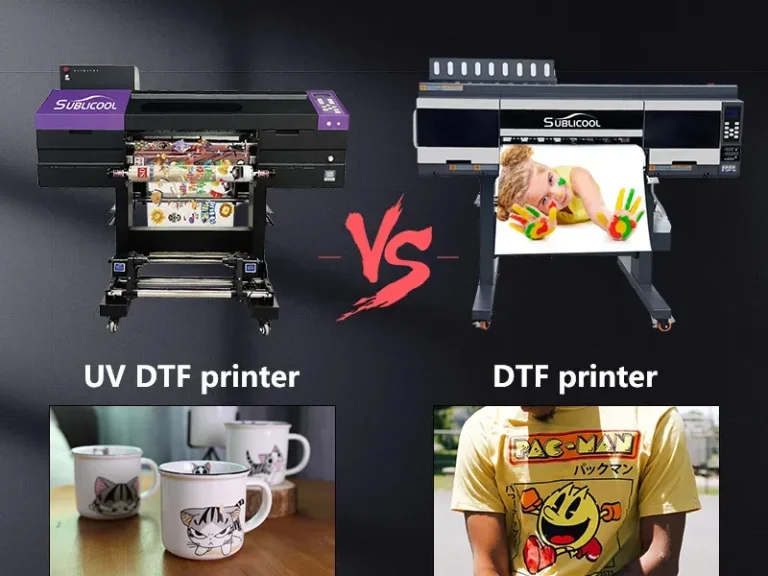

How does UV DTF printing compare to traditional apparel printing methods?

Unlike traditional apparel printing methods, which may involve longer drying times and less vibrancy, UV DTF printing cures ink instantly, resulting in brighter colors and greater durability. This method also allows for printing on a wider range of fabrics, enhancing design versatility.

Is UV DTF printing an eco-friendly printing technology?

Yes, UV DTF printing is considered eco-friendly because it produces minimal volatile organic compounds (VOCs) compared to conventional printing techniques. This makes it a sustainable choice for brands looking to adopt greener practices in custom apparel design.

What types of fabrics can be used with UV DTF printing?

UV DTF printing is highly versatile and can be used on various fabrics such as cotton, polyester, and blends. This flexibility allows designers to explore different materials while creating personalized apparel that appeals to diverse consumer preferences.

Can UV DTF printing handle small batch runs effectively?

Absolutely! UV DTF printing offers efficient production speeds, making it ideal for small batch runs and quick-pivot orders. This capability allows businesses to rapidly respond to consumer demands and trends in the custom apparel market.

What trends are influencing the adoption of UV DTF printing in custom apparel?

The shift towards high-quality personalization and unique designs is significantly influencing the adoption of UV DTF printing. As consumers seek distinctive apparel, brands leveraging this technology can efficiently produce customized, high-quality products that meet modern market demands.

| Key Point | Description |

|---|---|

| Introduction | UV DTF is a revolutionary printing technology enhancing custom apparel design through its UV curing process. |

| Game-Changer Technology | UV DTF printing cures ink instantly, providing vibrant, durable prints compared to traditional methods. |

| Versatility in Fabric Options | Compatible with various fabric types, allowing diverse design possibilities for designers. |

| Eco-Friendly Process | Lower VOC emissions compared to traditional inks, appealing to environmentally-conscious consumers. |

| Efficiency and Speed of Production | Instant curing leads to quicker production times, especially beneficial for small batches and rapid orders. |

| Unmatched Detail and Color Depth | High resolution and rich colors allow for intricate designs that stand out in the market. |

| Market Trends | Customization demand is driving the adoption of UV DTF printing for unique and high-quality designs. |

| Competitive Edge | Brands using UV DTF gain advantages by meeting consumer expectations for personalized and quality products. |

| Future Outlook | Predicted growth in UV DTF usage as companies seek to enhance product quality and sustainability. |

Summary

UV DTF printing is a revolutionary technology that is transforming the custom apparel industry by allowing for high-quality, vibrant prints with exceptional durability. Its instant curing process and eco-friendliness not only appeal to the modern consumer but also empower businesses to respond quickly to dynamic market trends. As brands increasingly adopt UV DTF printing, they are equipped to meet the evolving demands for customization and quality, ensuring they remain competitive in a fast-paced landscape. Looking ahead, UV DTF printing is set to reshape custom apparel design by integrating quality, speed, and sustainability into production processes, establishing itself as a mainstay in the industry.