DTF transfers have transformed the world of textile printing, offering artists and entrepreneurs an incredible way to showcase vibrant designs on various fabrics. This innovative heat transfer method allows users to print intricate images and patterns directly onto a special film, which can then be applied to garments seamlessly. With the ability to produce high-quality results that resist fading, DTF printing has become a favorite among those looking to elevate their creative printing techniques. Whether you’re customizing t-shirts, tote bags, or more, this method provides the flexibility and durability perfect for modern designs. In this guide, we’ll explore the art of DTF transfers and provide you with key tips for achieving stunning results.

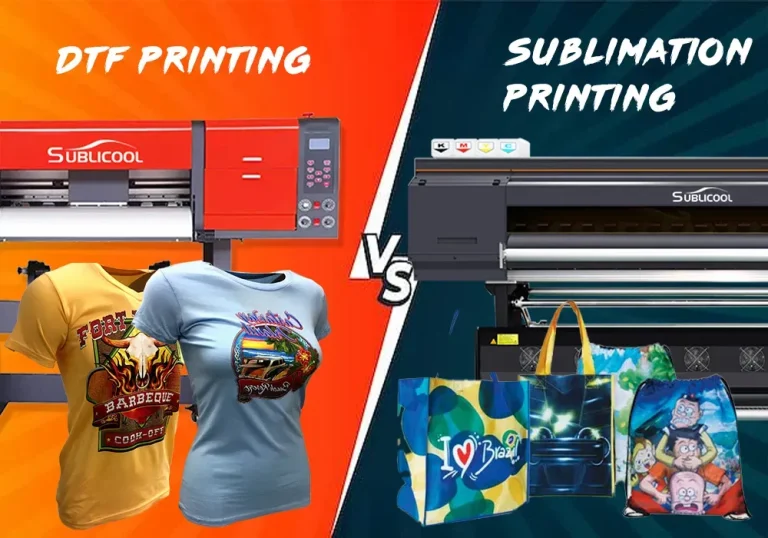

Direct-to-Film printing, often referred to as DTF printing, represents a groundbreaking approach to creating eye-catching designs that captivate audiences. This creative printing technique involves using a specialized film and high-quality inks to transfer dynamic images onto fabric, making it a go-to option for apparel decorators and designers alike. As a versatile alternative to traditional methods, such as screen printing and heat transfer vinyl, DTF offers a unique combination of affordability and vivid color reproduction. In the realm of textile printing, this method stands out for its ability to produce vibrant graphics that remain steadfast even after multiple washes. Join us as we delve deeper into the intricacies of this exciting technology and discover how to make the most of DTF transfers.

The Evolution of DTF Printing Technology

DTF printing technology has rapidly evolved, becoming a game-changer in the textile printing industry. This innovative technique utilizes advanced printing methods that allow for detailed designs with vibrant colors to be transferred directly onto various fabrics. Unlike traditional methods, DTF transfers can produce intricate details and gradients, making them a favorite among graphic designers and entrepreneurs in the fashion sector. The growing accessibility of DTF printers has enabled many to experiment with creative printing techniques, leading to a surge in unique apparel and customized goods.

With the fusion of technology and creativity, DTF printing has paved the way for artistic expression. The flexibility of this method means designers can create everything from bold logos to intricate patterns on cotton, polyester, and blends. Moreover, advancements in durability and vibrancy of DTF inks have improved, ensuring that prints remain stunning and resilient, even after several washes. Understanding this evolution is essential for creators who want to leverage DTF technology to its fullest potential.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a printing method where designs are printed on a specialized film and then transferred onto fabric using heat and pressure. This heat transfer method ensures vibrant designs with excellent adhesion to various fabrics, making it a popular choice for custom apparel and textiles.

How can I create vibrant designs using DTF printing?

To create vibrant designs with DTF printing, use high-quality RGB color profiles and high-resolution images. Incorporating layering and transparency effects can enhance visual depth, making your DTF prints pop with color and interest. Choosing the right DTF inks and films is also crucial for achieving vibrant results.

What types of fabrics work best for DTF transfers?

For optimal results with DTF transfers, smooth fabrics like cotton and polyester blends are recommended. These materials allow the DTF inks to adhere better and maintain vibrancy, ensuring that the colors shine through after the transfer process.

What are common mistakes to avoid when using DTF printing?

Some common mistakes to avoid in DTF printing include incorrect printer settings, which can lead to loss of detail, and skipping test prints that help troubleshoot potential issues. It’s also important to follow proper temperature and pressure guidelines during the transfer process for best results.

How do I ensure the longevity of my DTF prints?

To maximize the lifespan of your DTF transfers, follow proper aftercare practices: wash garments inside out in cold water, avoid high-temperature drying, and educate customers on caring for their products. These steps can help maintain the vibrancy and quality of DTF prints over time.

What advancements are happening in DTF printing technology?

DTF printing technology is evolving with the introduction of eco-friendly inks and films, appealing to businesses and consumers interested in sustainability. Additionally, the integration of DTF printing with e-commerce platforms makes it easier to sell custom products, further enhancing creative opportunities for designers.

| Key Point | Details |

|---|---|

| Understanding DTF Technology | DTF transfers involve printing designs onto film which is then applied to fabric using heat and pressure, allowing for vibrant designs on various materials. |

| Design Considerations for Vibrancy | Utilize RGB color profiles, high-resolution images, and layering techniques to enhance vibrancy in designs. |

| Choosing the Right Materials | Select high-quality DTF inks and films as well as suitable fabrics like cotton and polyester blends for best results. |

| Applying Transfers Correctly | Maintain proper temperature (320°F to 350°F) and pressure during application for effective adhesion. |

| Advancements and Trends | Focus on eco-friendly inks and integration with e-commerce to attract a broader audience. |

| Common Mistakes to Avoid | Ensure correct printer settings and always conduct test prints to minimize costly errors. |

Summary

DTF transfers have transformed the printing landscape, offering vibrant design possibilities across various fabrics. By mastering the technology and making informed choices regarding design, materials, and application, you can achieve eye-catching results that stand out. Keep in mind the continual advancements, particularly in sustainable practices, which further enhance the appeal of DTF printing. Embrace this innovative technique to turn your creative visions into beautiful, long-lasting products.