When it comes to DTF printing, selecting the right fabrics can significantly influence the quality and longevity of your designs. Direct-to-Film printing opens up a world of possibilities for vibrant graphics, but it’s crucial to understand which materials work best for achieving stunning results. The best fabrics for printing not only ensure beautiful color transfer but also boost the durability of your prints. In this guide, we will delve into the leading DTF printing fabrics, from reliable cotton for DTF printing to versatile polyester printing materials, highlighting their unique properties and benefits. Discover how each fabric type can transform your printing projects into vivid, lasting masterpieces.

DTF printing, an innovative technique for transferring images onto various materials, has gained popularity across industries. This method amplifies the potential of direct film transfer technology, making it essential to choose suitable substrates for optimal results. Fabrics like cotton-polyester blends and specialized synthetic materials contribute to exceptional print clarity and robustness. Exploring alternative terms such as direct-to-film textiles or optimal substrates for DTF applications will also broaden your understanding of fabric choices available for this dynamic printing method. By familiarizing yourself with these alternatives, you can make informed decisions that enhance the quality of your printed products.

Understanding DTF Printing: An Overview

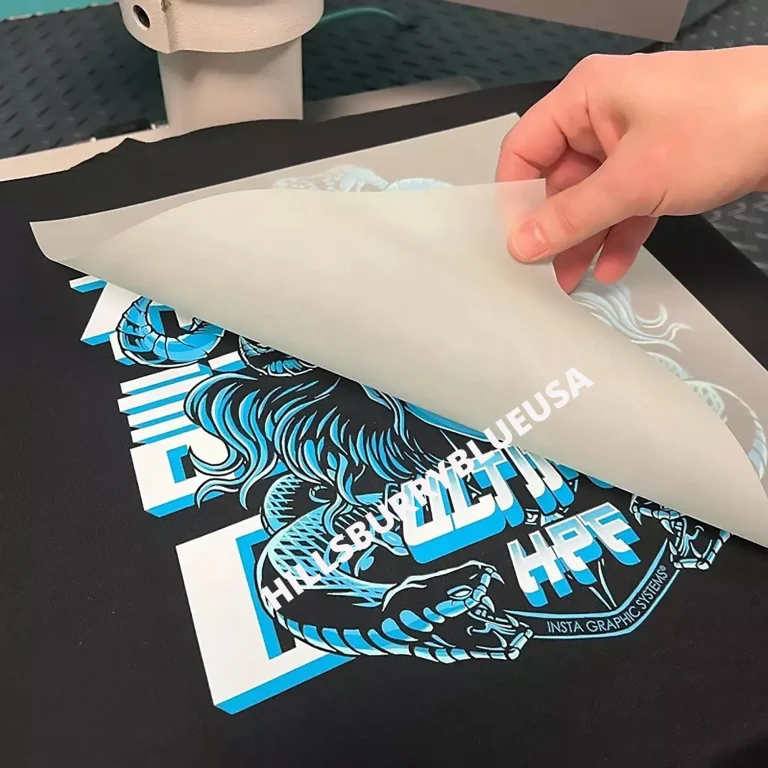

Direct-to-Film (DTF) printing is a revolutionary method that has transformed the textile industry, allowing for easier and more vibrant printing options. Unlike traditional screen printing and heat transfer methods, DTF printing directly applies the design onto a special film, which is then transferred to the fabric using heat and pressure. This technique offers unparalleled color vibrancy and allows for intricate designs that may be challenging to achieve with other methods. With consistent advancements in DTF technology, it’s becoming the preferred choice among decorators and designers looking for high-quality prints.

Moreover, DTF printing has a significant advantage over other methods in terms of versatility. It can be applied to a wide variety of fabrics, whether natural or synthetic, making it an attractive option for manufacturers. From custom apparel to promotional items, DTF printing opens the door to creative freedom, allowing businesses to meet diverse consumer demands. As the popularity of DTF printing continues to grow, understanding its fundamentals is vital for anyone interested in maximizing their printing capabilities.

Best Fabrics for DTF Printing: Cotton vs. Polyester

When it comes to choosing the best fabrics for DTF printing, cotton and polyester are often at the forefront of discussions. Cotton remains a strong choice for many due to its natural properties. This fabric absorbs inks beautifully, resulting in vibrant designs that stand the test of time. The natural fiber helps in achieving rich color depth and ensuring durability, making cotton a classic choice for t-shirts and casual wear. Its comfort also makes it a preferred option among consumers, particularly in clothing meant for everyday use.

On the other hand, polyester has carved out its niche in the realm of DTF printing, especially in performance and activewear. It boasts excellent moisture-wicking properties and is more resilient against fading and wear over time. This synthetic fabric can achieve extremely bright and crisp prints, appealing to both manufacturers and consumers looking for functional garments. Understanding the differences between these two materials helps businesses make informed decisions tailored to their target markets.

The Advantages of Cotton-Polyester Blends in DTF Printing

Cotton-polyester blends have emerged as a popular solution for manufacturers looking to balance the strengths of both cotton and polyester. These fabrics combine the best features of natural and synthetic fibers, resulting in prints that are both vibrant and durable. Unlike 100% cotton, these blends tend to be less prone to shrinkage and wrinkling, effectively resulting in garments that require less maintenance. Many brands opt for these blends to optimize production costs while maintaining quality, making them a reliable choice for DTF printing.

Additionally, the versatility of cotton-polyester blends allows them to be used across various apparel styles, from casual wear to corporate clothing. The blend can cater to diverse tastes and needs, which is essential for businesses aiming for broad market appeal. By utilizing these blended fabrics in DTF printing, manufacturers can achieve excellent print quality without compromising on comfort or style, thus expanding their product offerings efficiently.

Fleece and Knit Fabrics: Unique Options for DTF Printing

Fleece fabrics bring a level of comfort and warmth that is particularly appealing for seasonal garments like hoodies and blankets. When utilized in DTF printing, fleece allows for remarkable color adherence, resulting in cozy items that are adorned with eye-catching prints. This soft, plush material is perfect for casual apparel, merging aesthetic appeal with functionality. However, attention must be given to the type of fleece used to ensure optimal print results, as some variations may pose challenges regarding ink adhesion.

Knit fabrics also present unique opportunities in DTF printing, especially for fitted apparel. The elasticity of knit structures allows for a snug and tailored fit, making them an excellent choice for athletic and performance wear. While DTF printing can work well on knits, ensuring that the knit’s texture allows proper ink adherence is critical. Therefore, selecting the right knit is essential for achieving a balance between design integrity and garment functionality, ensuring each piece not only looks good but performs well during wear.

Advanced Performance Fabrics: Elevating DTF Printing

As the demand for high-performance apparel grows, specialized fabrics designed for athletics and various outdoor activities have become increasingly relevant for DTF printing. These advanced performance fabrics are engineered to offer breathability, moisture management, and durability, meeting the rigorous needs of athletes and active individuals. Utilizing DTF printing on these fabrics results in prints that not only look fantastic but also withstand the stresses of physical activity.

Moreover, the integration of performance fabrics in DTF printing extends benefits such as raising brand visibility and providing functional attributes that consumers seek. Innovative printing technologies ensure that the prints remain vibrant even after numerous washes while maintaining the integrity of the fabric’s performance characteristics. This blend of functionality and aesthetics positions manufacturers at the forefront of the market, catering to niche segments within the activewear industry while utilizing progressive printing techniques.

Innovations in DTF Printing Technology and Fabric Compatibility

Recent advancements in DTF printing technology have vastly expanded the range of fabrics compatible with this printing method. Innovations now allow for high-definition prints that are achievable on previously unsuitable materials, broadening creative possibilities for designers and brands alike. These advancements not only improve print quality but also optimize production processes, resulting in higher efficiency and reduced costs.

Furthermore, with these developments, businesses can expand their offerings to include a more diverse range of products. The ability to achieve superior print quality on various fabric types gives brands the flexibility to innovate and captivate different markets. This level of adaptability in DTF printing opens up considerable opportunities for businesses looking to create unique designs while leveraging the benefits of new printing technologies.

Frequently Asked Questions

What are the best fabrics for DTF printing?

The best fabrics for DTF printing include 100% cotton, high-quality polyester, cotton-polyester blends, fleece, and specialized performance fabrics. Cotton provides excellent color richness and durability, while polyester excels in moisture management and vibrant prints. Blends combine the advantages of both materials, making them versatile for various applications.

Can I use cotton for DTF printing?

Yes, 100% cotton is highly recommended for DTF printing due to its natural fiber composition, which allows for excellent ink adhesion and vibrant color transfer. Cotton fabrics produce sharp, saturated prints that are ideal for apparel.

Is polyester suitable for DTF printing?

Absolutely! Polyester is an excellent choice for DTF printing, especially in sportswear. Its durability, moisture-wicking properties, and ability to deliver bright, vivid prints make it ideal for high-performance garments.

What are the advantages of cotton-polyester blends for DTF printing?

Cotton-polyester blends offer the best of both worlds; they combine the vibrant color retention of cotton with the durability and reduced shrinkage of polyester. These blends are versatile and often yield excellent print quality.

Are performance fabrics compatible with DTF printing?

Yes, performance fabrics made from synthetic blends are compatible with DTF printing. They provide breathability and moisture management, making them suitable for high-performance clothing lines while delivering impressive print quality.

What is the role of adhesive in DTF printing?

The use of the right adhesive powder is crucial in DTF printing. It ensures that the prints adhere well to various fabrics, remain flexible, and provide a long-lasting finish without compromising the softness of the garment.

| Fabric Type | Pros | Cons |

|---|---|---|

| Cotton | – Vibrant Colors – Durable Prints – Comfortable Feel |

– Shrinkage – Limited Stretch |

| Polyester | – Durability – Moisture Control – Bright Prints |

– Less Breathable – Limited Comfort |

| Cotton-Polyester Blends | – Versatility – Enhanced Print Quality – Reduced Wrinkle |

– Variable Quality – Less “Pure” Cotton Feel |

| Fleece and Knit Fabrics | – Warmth – Softness |

– Pilling – Limited Styles |

| Performance Fabrics | – Moisture-Wicking – Durability |

– Cost – Care Requirements |

Summary

Fabrics for DTF Printing are crucial in determining the vibrancy and durability of the final product. The right fabric choice not only impacts the appearance of prints but also their longevity, especially in demanding applications like sportswear and custom apparel. Popular options like cotton and polyester lead the way with their distinct advantages, while blends, fleece, and performance fabrics provide alternatives that maximize comfort and functionality. Keeping abreast of the latest advancements in DTF technology ensures that even lesser-known fabrics are suitable for high-quality printing, enhancing overall product value and appeal. Therefore, understanding these fabric characteristics is essential for anyone involved in DTF printing, paving the way for successful outcomes in both personal and professional endeavors.