DTF transfers, or Direct to Film transfers, are revolutionizing the world of custom apparel printing with their ability to effortlessly produce vibrant and detailed designs. This innovative method utilizes advanced printing technology to deliver high-quality graphics that adhere seamlessly to a variety of fabrics. As more businesses recognize the numerous DTF printing benefits—such as cost-effectiveness and versatility in garment options—this technique is quickly becoming a favored choice among apparel printers. Moreover, DTF transfers contribute to the growing trend of sustainable fashion, allowing for eco-friendly production methods without compromising on quality. With their impressive capabilities, DTF transfers represent the future of custom garment printing, making them a game-changer in the industry.

Direct to Film printing, often referred to as DTF printing, is an emerging technique that is capturing attention within the custom apparel sector. This process streamlines the transfer of intricate designs onto fabrics, which is gaining traction for its combination of high-quality output and efficient production. As the demand for personalized clothing rises, this innovative method offers businesses the ability to provide unique apparel while adapting to trends in sustainable fashion. Companies are increasingly looking to DTF transfers as a solution for versatile garment printing that supports both creative expression and eco-conscious practices. Ultimately, this modern printing method is reshaping how custom garments are produced and delivered to consumers.

Understanding DTF Transfers: The New Frontier of Custom Apparel Printing

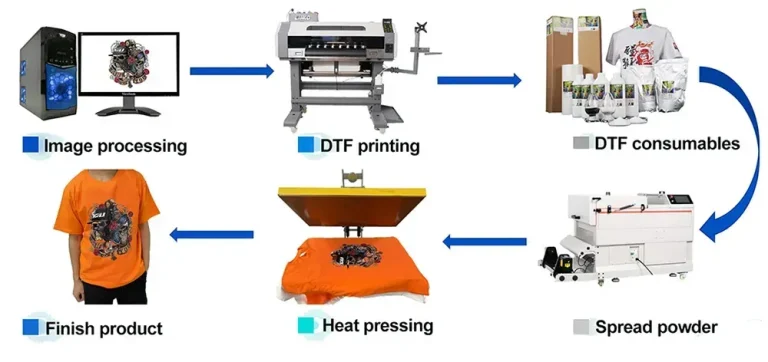

Direct to Film (DTF) transfers represent a transformative advancement in custom apparel printing technologies. This process starts with the digital printing of designs onto a specialized film, which can then be effortlessly applied to various fabrics. Unlike traditional printing methods, such as screen printing that demands multiple screens for each color, DTF printing harnesses advanced ink technology to create vibrant, high-definition prints without demanding extensive setup time. As a result, businesses can produce high-quality apparel in a fraction of the time previously required.

Moreover, DTF transfers are renowned for their flexibility. They can adhere to a range of materials, including cotton and polyester blends, making them a favorite choice among custom garment printers. This versatility allows businesses to produce a broader array of products, appealing to a wider audience. As the demand for unique and customizable apparel increases, understanding the nuances of DTF technology becomes essential for keeping pace in a competitive market.

Top Benefits of DTF Printing for Custom Apparel

One of the standout advantages of DTF printing is its ability to reproduce intricate designs with unparalleled clarity and color fidelity. This advancement is particularly appealing for brands aiming for high-quality visuals, whether it’s a detailed logo or vibrant artwork. DTF transfers maintain their quality after several washes, ensuring that the designs remain as striking as they were on the day of printing. Such durability is crucial for businesses that sell apparel intended for regular wear.

Additionally, DTF printing presents an economical solution for small batch orders. Unlike traditional methods that require hefty upfront investments, DTF printing involves more accessible equipment and material costs, making it ideal for startups and small businesses. This cost-effectiveness, combined with the ability to produce unique designs quickly, positions DTF as a leading choice for entrepreneurs navigating the custom apparel landscape.

Advancements Driving the DTF Printing Revolution

Recent technological advancements in Direct to Film printing are revolutionizing the industry. As new printers with improved functionalities emerge, the quality and durability of DTF prints have significantly enhanced, making it easier for businesses to adopt this modern printing technique. These advances not only cater to aesthetic appeal but also ensure longevity, appealing to environmentally-conscious consumers seeking sustainable fashion options.

Furthermore, with sustainability becoming more than just a trend in fashion, many DTF printing companies are now focusing on eco-friendly inks and techniques that minimize waste. By incorporating sustainable practices into their operations, custom garment printers can align themselves with the growing demand for responsible fashion without compromising on quality.

Market Trends Shaping the Future of DTF Printing

The explosion of e-commerce has profoundly impacted the demand for customized apparel. With consumers increasingly looking for unique products to express their individual styles, DTF printing stands out as the perfect solution due to its precision and speed. Businesses can now offer personalized items quickly, meeting consumer expectations for rapid delivery, which has become essential in our fast-paced society.

As brands strive to create memorable shopping experiences online, DTF printing introduces a degree of customization that allows for rapid product iterations. By leveraging this technology, companies can respond swiftly to market trends and consumer preferences, ensuring they remain competitive in an ever-evolving landscape.

Navigating Challenges in DTF Printing

Despite the manifold benefits of DTF transfers, there are challenges that businesses must navigate to fully capitalize on this technology. For instance, while the equipment can be more affordable than traditional printing methods, the initial investment in quality DTF printers can still be considerable for some companies. Furthermore, there’s a need for ongoing maintenance and potential upgrades, which can add to the overall financial outlay.

Additionally, entering the realm of DTF printing comes with a learning curve. New users often face challenges in mastering the optimal temperature and pressure settings for print transfers. Proper training and practice are critical for achieving the best results, as mismanaged application can lead to poor-quality prints that may deter consumers.

The Comfort Factor: DTF Prints vs. Other Techniques

While DTF printing offers impressive durability and vibrant colors, some customers might find that DTF prints do not have the same soft finish as garments produced through direct-to-garment (DTG) printing. This difference can be a crucial consideration for brands focusing on comfort and feel, especially in the premium apparel market. Consumers often prioritize how clothing feels against the skin, which could drive their choice towards brands using softer printing techniques.

Brands must weigh these factors carefully; balancing the advantages of DTF printing with customer comfort preferences is essential for long-term success. By offering a mix of printing techniques that cater to different customer needs and preferences, businesses can enhance their product lines while maximizing appeal across diverse consumer segments.

Frequently Asked Questions

What are the advantages of using DTF transfers in custom apparel printing?

DTF transfers offer several advantages in custom apparel printing, including high-quality output with intricate designs and vibrant colors. This method is versatile, allowing printing on various fabrics like cotton and polyester. Additionally, DTF printing is cost-effective for small batch orders, simplifies workflows compared to traditional methods, and has a rapid production time, making it ideal for businesses looking to meet customer demands effectively.

How does DTF printing differ from traditional methods like screen printing?

DTF printing differs from traditional screen printing by eliminating the need for multiple screens for different colors. Instead, intricate designs are printed onto a special film, which is then transferred to the fabric using heat and pressure. This not only speeds up the printing process but also reduces setup complexity, allowing for more efficient and flexible production of custom garments.

Is DTF printing a sustainable option for custom garment printing?

Yes, DTF printing is increasingly becoming a sustainable option in the custom garment printing industry. Many manufacturers are developing eco-friendly inks and processes to minimize waste. As the trend towards sustainable fashion grows, adopting DTF printing allows businesses to offer high-quality products while aligning with environmental initiatives, appealing to eco-conscious consumers.

Can DTF transfers be applied to all types of fabrics?

DTF transfers are highly versatile and can be applied to a wide range of fabrics, including cotton, polyester, and fabric blends. This adaptability makes DTF printing a favored choice for businesses that want to produce custom garments across different fabric types without compatibility issues, ensuring vibrant and durable prints regardless of the material.

What challenges might businesses face when using DTF printing?

While DTF printing has many advantages, businesses may encounter challenges such as the initial investment in specific equipment and a learning curve associated with mastering application techniques. Additionally, some consumers may find that DTF prints have a different texture compared to those produced through methods like direct-to-garment (DTG) printing, which can impact customer preferences related to apparel comfort.

How has the rise of e-commerce influenced the demand for DTF transfers?

The surge in e-commerce has significantly influenced the demand for DTF transfers, as more consumers seek personalized and unique apparel online. DTF printing meets this demand by allowing quick turnaround times and customization options, making it an ideal solution for e-commerce businesses wanting to provide tailored products efficiently while maintaining high-quality standards.

| Feature | Description |

|---|---|

| DTF Transfers | A modern printing technique for transferring vibrant designs on various fabrics. |

| Quality and Detail | Excels at reproducing intricate designs with vibrant colors; maintains quality after multiple washes. |

| Versatility | Can be used on a range of fabrics, including cotton, polyester, and blends. |

| Cost-effective for Small Runs | Economical setup for small batch orders, appealing to startups. |

| Simplicity | Easier management than traditional methods; quicker production times. |

| Recent Developments | Technological advancements and eco-friendly initiatives enhancing DTF printing. |

| Market Trends | Rise of e-commerce and demand for fast turnaround times favor DTF printing. |

| Challenges | Investment in equipment and learning curve to master application techniques. |

Summary

DTF transfers represent a transformative shift in the realm of custom apparel printing. This innovative technique combines high-quality prints with versatility, making it an optimal choice for a wide array of fabrics. As the market trends toward sustainability and personalization, DTF transfers are set to meet the demands of modern consumers quickly, offering rapid turnaround times that keep pace with e-commerce growth. With advancements in technology enhancing print quality and durability, DTF transfers not only provide businesses with an efficient solution but also cater to the rising consumer preference for unique designs. As such, DTF transfers are positioned to be a cornerstone in the future of custom garment decoration.