DTF transfers, or Direct-to-Film transfers, are rapidly transforming the landscape of t-shirt printing, offering a fresh, innovative approach to custom apparel decoration. Gone are the days when screen printing dominated the market; today, DTF printing is stepping into the spotlight with its ability to deliver vibrant, durable prints on a variety of fabrics. This game-changing technology not only ensures a high-quality finish but also caters to the growing demand for personalized garments in an increasingly competitive industry. By utilizing a process that effectively bonds ink to fabric through an adhesive powder, DTF transfers promise exceptional longevity and detail, making them a popular choice among businesses and individuals alike. Join us as we delve into the world of DTF printing and uncover how it is shaping the future of sustainable printing and custom apparel production.

Known by various names, such as direct-to-film printing and custom garment transfers, DTF printing represents a significant shift in how businesses approach apparel decoration. This modern technique expertly prints designs onto a specialized film that can be heat-transferred onto different textiles, making it a versatile choice for contemporary fashion. As companies strive for unique ways to stand out, this innovative method serves up high-resolution graphics while significantly reducing time and resources compared to traditional printing practices. With an emphasis on eco-friendly production, many brands are embracing this sustainable printing option to meet consumer demand for conscious manufacturing. Ultimately, the adoption of DTF solutions allows for creativity in the fashion realm while promoting an eco-aware approach to custom apparel.

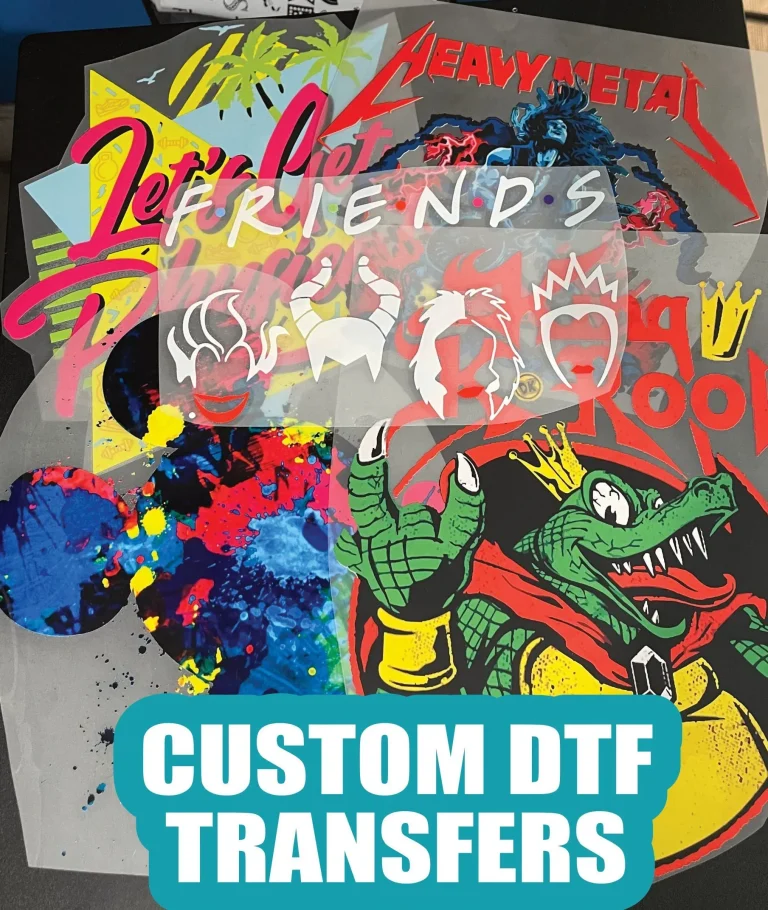

Introduction to DTF Printing Technology

Direct-to-Film (DTF) printing is emerging as a game-changer in the world of custom t-shirt printing. It involves the innovative process of printing high-quality designs onto a specialized film, which is then transferred onto garments using heat. DTF technology is not just an evolution of previous printing methods; it represents a paradigm shift in how apparel is created and personalized. Its ability to produce vibrant and intricate designs makes it the go-to choice for businesses looking to create custom apparel that stands out in a competitive market.

The DTF printing process is characterized by its versatility and ease of application. Unlike traditional screen printing or even direct-to-garment (DTG) printing, DTF can efficiently adhere to a wide range of fabric types such as cotton, polyester, and various blends, making it a favorite among custom apparel specialists. This versatility not only opens up new realms for creativity, but it also allows businesses to cater to diverse customer preferences, truly revolutionizing the garment decoration landscape.

Exploring the Quality of DTF Transfers

One of the most celebrated features of DTF transfers is the unparalleled quality of prints they produce. With DTF printing, manufacturers can create intricate designs with vivid colors that pop off the fabric. The unique adhesive powder used in the transfer process ensures that the ink adheres firmly, resulting in long-lasting prints that remain vibrant even after numerous washes. This level of durability and detail is particularly crucial for brands aiming to make a lasting impression with their merchandise.

In addition to producing high-quality prints, DTF technology allows for complex designs that would otherwise be challenging to achieve with traditional methods. Whether it’s dynamic graphics or photographic images, DTF’s capability for precision and clarity enables creators to push the boundaries of what custom apparel can look like. This high level of design fidelity is essential in today’s fashion-driven market, where consumers expect not only quality but uniqueness in their clothing choices.

DTF Transfers and Their Versatility in Custom Apparel

DTF transfers showcase remarkable versatility, which is one of their most compelling features for custom apparel businesses. The technology can effectively be used on a variety of fabrics, including cotton, poly-blends, and advanced textile materials. This adaptability means businesses can offer a broader range of products—from casual t-shirts to high-end fashion items—thus catering to diverse market demands. This is especially important in an era where personalization is key to consumer satisfaction.

Moreover, DTF printing’s flexibility allows for the production of both small and large runs of prints without compromising quality or increasing costs excessively. This aspect is vital for businesses that want to respond quickly to market trends or customer inquiries, as they can produce garments on-demand without carrying extensive inventory. Its broad application potential has made DTF a favorite among start-ups and established brands alike, solidifying its position in the custom apparel industry.

The Efficiency and Cost-Effectiveness of DTF Printing

Cost-effectiveness is a critical consideration for businesses looking to enter the custom apparel market, and DTF printing shines in this area. While the initial investment in DTF equipment might seem daunting, the long-term savings associated with reduced labor and material waste can significantly offset these costs. In fact, as technology improves, the overall costs of DTF printing are declining, making it accessible even for small operations that wish to provide high-quality prints without straining their budgets.

The efficiency of DTF transfers is also noteworthy; the process is streamlined, allowing for quick turnaround times on custom orders. With traditional methods often requiring complex setups and longer lead times, DTF offers a more agile solution for companies that want to maintain a competitive edge. This flexibility allows businesses to respond to customer preferences more efficiently, making it feasible to cater to limited runs or rapidly changing trends in a cost-effective manner.

Sustainability in DTF Printing Practices

As sustainability becomes an essential factor in consumer purchasing decisions, DTF technology stands out for its environmentally friendly characteristics. Unlike many traditional printing methods that rely heavily on water and toxic inks, DTF printing minimizes waste and uses non-toxic materials. This alignment with contemporary eco-conscious standards attracts customers who prioritize sustainability in their fashion choices, creating new avenues for brand loyalty.

Furthermore, DTF printing’s capacity to produce only the number of garments needed for an order, rather than large batches that may go unsold, significantly reduces production waste. This strategy not only lowers the environmental impact of the fashion industry but also fosters responsible consumption. As businesses increasingly align with sustainable practices, integrating DTF technology not only shows commitment to ecological responsibility but also resonates with a growing demographic of eco-aware consumers.

The Future of DTF Transfers in the Custom Apparel Industry

The rapid adoption of DTF transfers signals a transformative change in the custom apparel landscape. As more brands integrate this technology into their production workflows, it is reshaping how garments are designed, produced, and marketed. The flexibility offered by DTF printing can cater to the on-demand nature of modern retail experiences, making it increasingly critical as e-commerce continues to evolve. This shift highlights a future where customization is not only efficient but also commonplace.

Technological advancements and innovations in materials used for DTF printing will likely expand the range of possibilities for designers and apparel companies. As the barriers to entry decrease, more businesses will be able to invest in DTF technologies and explore its capabilities. This evolution will foster creativity and innovation in printing techniques, leading to an even more eclectic and vibrant custom apparel market in the years to come.

Frequently Asked Questions

What are DTF transfers and how do they work in t-shirt printing?

DTF transfers, or Direct-to-Film transfers, are a printing method where designs are printed onto a specialized film. The film is then heat-pressed onto t-shirts, creating vibrant, durable images that adhere well to different fabrics. This process uses a unique adhesive powder that ensures the prints last through multiple washes, making DTF printing an ideal choice for custom apparel.

What advantages do DTF transfers offer over traditional t-shirt printing methods?

DTF transfers provide several advantages over traditional methods like screen printing and DTG printing. They produce high-resolution, colorful prints, are versatile across various fabrics, and ensure quick turnaround times. Moreover, DTF printing is cost-effective, especially for small batches, making it an excellent choice for businesses that need flexibility in their custom apparel offerings.

Can DTF printing be used on various fabric types for custom apparel?

Yes, DTF printing is highly versatile and can be applied to a variety of fabric types, including cotton, polyester, and blends. This flexibility makes DTF transfers suitable for a wide range of custom apparel, from t-shirts and hoodies to accessories, catering to the diverse needs of consumers in the fashion market.

How does DTF printing contribute to sustainable printing practices?

DTF printing contributes to sustainable printing practices by utilizing non-toxic inks and requiring significantly less water compared to traditional printing methods. Additionally, it minimizes waste by allowing businesses to print only what is needed, which aligns with the growing consumer demand for eco-friendly and sustainable products in custom apparel.

What is the cost-effectiveness of DTF transfers in the custom apparel market?

DTF transfers are known for their cost-effectiveness, especially for short run orders. While the initial investment in DTF printing equipment can be substantial, advancements in technology have lowered costs. Businesses can produce high-quality custom apparel without incurring excessive expenses, making DTF printing an attractive option for both startups and established companies.

What is the future of DTF printing in the custom apparel industry?

The future of DTF printing in the custom apparel industry looks promising as more brands and manufacturers adopt this technology into their production processes. With advancements in machine capabilities and materials, along with increasing demand for on-demand manufacturing, DTF transfers are set to become a significant player in garment decoration, offering innovative solutions to meet market needs.

| Key Points | Description |

|---|---|

| What are DTF Transfers? | A printing process that uses a film to transfer designs to fabrics with heat and pressure, allowing for high-resolution prints on various materials including cotton and polyester. |

| Quality and Versatility | DTF transfers are known for vibrant colors and intricate details, making them suitable for a wide range of apparel customization. |

| Ease of Use and Efficiency | The printing process is straightforward and cost-effective, supporting quick turnarounds and accommodating small orders without high setup costs. |

| Cost-Effectiveness | Lower initial investments and overhead costs than traditional methods, allowing small operations to produce high-quality garments economically. |

| Environmental Impact | Uses non-toxic inks and consumes less water, aligning with sustainability goals and reducing fashion production’s environmental footprint. |

| Industry Adoption | Major brands are adopting DTF in production, investing in resources and training to harness its capabilities as e-commerce grows. |

Summary

DTF transfers have fundamentally transformed the t-shirt printing industry by offering exceptional quality, versatility, and efficiency. These innovative printing solutions not only meet the diverse needs of designers and brands but also cater to the modern consumer’s desire for sustainable and unique apparel. As more businesses invest in DTF technology, it is evident that DTF transfers will play a crucial role in shaping the future landscape of custom garment production, driving advancements, and setting new standards in quality.