DTF printing techniques, also known as Direct-to-Film printing, are rapidly transforming the landscape of custom textile printing. This state-of-the-art process allows for seamless transfer of designs from a film to a variety of fabrics, enabling artists and businesses to create stunning visuals with impeccable detail and vibrant colors. With a unique combination of the efficiency found in digital printing and the high print quality reminiscent of traditional screen printing, the DTF printing process is gaining traction among entrepreneurs looking to capitalize on custom apparel and promotional items. The advantages of DTF printing include its versatility across different materials, environmental sustainability with eco-friendly inks, and quick turnaround times that meet the demands of fast-paced markets. As the popularity of DTF continues to rise, understanding its fundamentals becomes essential for anyone interested in the textile printing industry.

Often referred to as Direct-to-Film or D2F printing, this innovative method is redefining the possibilities for textiles and custom graphics. This technology provides an efficient means to apply intricate designs onto fabrics, promising exceptional print quality and adaptability to various materials. Notably, DTF offers significant benefits for businesses, such as the ability to produce small runs cost-effectively and rapidly. With its eco-friendly inks, this printing method is also paving the way for more sustainable practices within the industry. Exploring DTF printing opens new doors for creativity and entrepreneurial opportunities in the realm of custom textile applications.

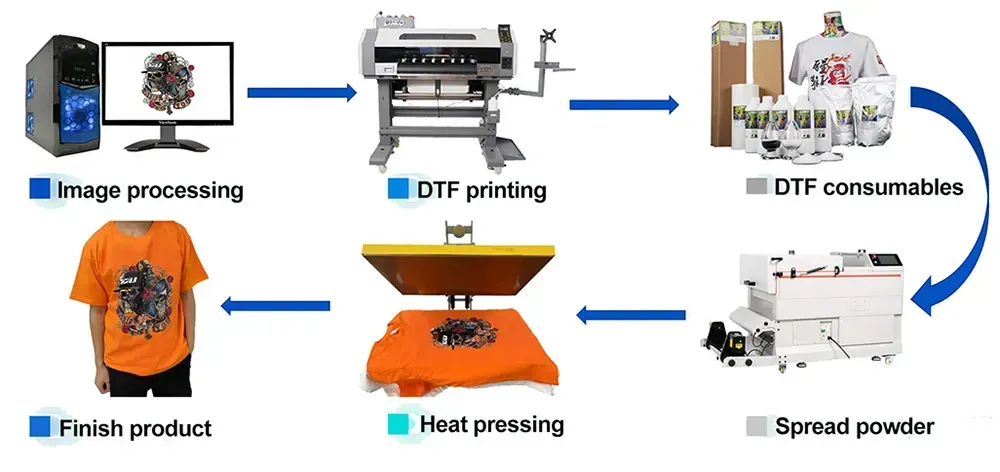

Understanding the DTF Printing Process

DTF printing, or Direct-to-Film printing, revolutionizes how designs are transferred to textiles by using a unique method that employs a film intermediary. This process begins with printing your design onto a special transfer film using digital printers that are equipped for high-quality outputs. Once the design is ready, the film is coated with a special adhesive powder which must then be cured using heat. This step is crucial, as it allows the adhesive to bond properly when applied to the fabric. Thereafter, when heat is applied to join the film with the textile, a profound transfer occurs that leaves a lasting imprint of your design.

What sets the DTF printing process apart from traditional methods such as screen printing or heat transfer is its ability to provide vibrant colors and intricate details without the need for extensive setup time. The versatility allowed by DTF technology means it can be used on various fabric types, making it highly effective for both small and large running jobs. DTF printing enables businesses to offer diverse product lines, from custom apparel to intricate fashion accessories, thereby appealing to a broader audience.

Moreover, the DTF printing process supports quick production cycles, making it ideal for businesses catering to trends that change rapidly. With the ability to print on demand, companies can maintain an agile inventory, responding more swiftly to consumer demands. The minimized turnaround times make DTF printing an advantageous choice for promotional events where quick delivery is crucial. It provides an edge for entrepreneurs and brands looking to step into the competitive market of custom textile printing.

Advantages of DTF Printing Techniques

The advantages of DTF printing are numerous, positioning it as a leading choice in modern textile production. First and foremost, DTF printing allows for superior print quality. Users often commend the bright, vivid colors and sharp details that can be achieved, rivaling common printing methods like sublimation or direct-to-garment (DTG) printing. This high-quality output is not only visually appealing; it also ensures durability, as these prints can withstand multiple washes without fading, making them suitable for everyday wear and promotional items alike.

In addition to quality, DTF printing offers economic benefits through cost-effectiveness, especially for small production runs. Companies can produce custom designs without incurring the heavy setup costs typically associated with traditional screen printing techniques. This aspect of DTF printing allows businesses to explore their creative ideas without the burden of high financial commitment, catering especially to startups and individual entrepreneurs.

Another significant advantage is the environmental aspect of DTF printing. As printers evolve, many use eco-friendly and water-based inks that lessen the ecological impact of textile printing. Many brands are conscious of sustainable practices and investing in DTF printing aligns with this ethos. Emphasizing sustainability is not just a trendy position; it fulfills consumer demands for ethical production methods that prioritize environmental integrity.

Exploring Creative Applications of DTF Printing

The potential applications of DTF printing techniques are virtually limitless, facilitating creative expression across various industries. From custom apparel that showcases unique designs to promotional merchandise that catches the eye, DTF printing allows for a multitude of artistic endeavors. Moreover, it’s not limited to clothing alone. Designers can explore printing on items like bags, hats, and even home textiles, maximizing the reach of their unique creations.

For fashion brands, DTF printing provides an exciting canvas for experimentation. It allows designers to visualize their creative ideas in real-time, adapting designs to better suit seasonal trends or consumer interests. This adaptability is vital in today’s fast-paced fashion world, where staying one step ahead can significantly impact success. Entrepreneurs can capitalize on niche markets by offering bespoke products that resonate with specific customer segments, thanks to the versatility and creativity enabled by DTF printing.

Furthermore, the use of DTF printing extends into promotional events and corporate branding strategies. Businesses can create personalized items for marketing purposes, such as custom t-shirts for events, branded merchandise, and unique giveaways that leave a lasting impression on potential customers. This capability enhances brand visibility and fosters customer loyalty, as clients appreciate the personal touch associated with custom printing.

DTF Printing vs. Other Textile Printing Methods

When comparing DTF printing to other textile printing methods, several distinct features emerge that highlight its strengths. Unlike traditional methods such as screen printing that require extensive setup and preparation, DTF printing offers a user-friendly experience that significantly reduces the time from concept to final product. This attribute makes DTF an attractive option for small businesses or individuals looking to produce high-quality custom products quickly and efficiently. The ability to print intricate designs with rich colors and details not only outmatches some traditional techniques but also brings it on par with more advanced processes like sublimation and DTG printing.

Additionally, the versatile nature of DTF printing stands out. While other methods may be limited to specific types of fabrics, DTF printing can be employed on a wide array of materials – from cotton and polyester to leather and specialized synthetic blends. This flexibility ensures that it remains a viable option for diverse applications, accommodating the demands of various markets.

Furthermore, the cost factor plays a significant role in deciding the best method for textile printing. DTF printing generally presents a more economical choice, particularly for small batch printing. As businesses navigate the challenges associated with custom textile printing, the ability to produce small quantities without exorbitant setup fees makes DTF a practical solution. In contrast, larger-scale operations needing multiple color screens may find other methods more suitable for higher volumes, thus making DTF printing ideal for bespoke and limited-edition items.

Challenges in DTF Printing and Solutions

While DTF printing offers many advantages, it also presents its own set of challenges that printers must navigate to achieve optimal results. One major challenge is the initial investment cost for specialized printers. Compared to traditional methods, DTF equipment can require a higher upfront expense, which might deter some small businesses from entering the market. To mitigate this, it’s essential for prospective users to thoroughly research equipment options, considering not just the purchase price but also the potential return on investment through increased productivity and quality.

Another challenge involves learning the specifics of the DTF printing process. For operators unfamiliar with this technology, the steep learning curve can be intimidating. Investing in training and workshops specifically dedicated to DTF printing can alleviate this burden, helping users master the nuances of the process while boosting their confidence. Furthermore, employing best printing practices and paying close attention to material selection can significantly improve output quality and reduce the likelihood of errors.

Lastly, ongoing education in printing technologies and trends is crucial for maintaining quality and staying competitive. Adapting to new advancements in DTF equipment and ink technology will ensure you’re not just keeping up, but leading in the industry. A commitment to continuous learning can help businesses maximize their potential in the ever-evolving world of custom textile printing.

Getting Started with DTF Printing: Essential Recommendations

Venturing into the world of DTF printing requires a thoughtful approach to ensure a successful start. First and foremost, conducting thorough research on the various printers and suppliers is crucial. Not all printers are built equal; therefore, identifying the right equipment that aligns with your business goals is paramount. Look for reliable manufacturers that provide support, have a good reputation for quality, and offer a range of substrates compatible with DTF printing. Gathering information on pricing and the different materials available will also aid in making an informed decision that supports both quality and budget.

Next, training should be prioritized. Whether you’re new to DTF printing or coming from another printing background, understanding the specific requirements and best practices is essential for success. Participating in courses, watching tutorials, and exploring hands-on workshops can greatly enhance your skillset and ensure the quality of your work. Furthermore, joining DTF printing communities online can provide invaluable insights and peer support that can shorten the learning curve.

Another important aspect is developing best practices for operation, especially in terms of file preparation and post-press care. High-quality prints rely on precise file formats and settings, which means understanding the requirements of DTF technology is essential. Implementing standard operating procedures for printing can result in consistent output that meets client’s expectations. Building a strong portfolio of your work can highlight the versatility and quality of DTF printing, demonstrating to potential clients the range of possibilities that this printing technique offers. This strategic approach will expand your marketing outreach while positioning your business favorably in the competitive landscape of custom textile printing.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct-to-Film printing, is a textile printing technique that transfers designs from a special film onto fabrics using heat. This process is efficient and allows for vibrant, high-quality prints on various materials, including cotton, polyester, silk, and leather.

What are the advantages of DTF printing compared to traditional methods?

The advantages of DTF printing include high print quality with sharp details and vivid colors, cost-effectiveness for small production runs, quick turnaround times, and the ability to print on a variety of fabrics, including both light and dark textiles.

How does the DTF printing process differ from traditional screen printing?

Unlike traditional screen printing, which requires multiple setups for different colors, DTF printing uses digital design and a transfer film, allowing for faster production and the ability to produce intricate designs without significant setup costs.

What materials can be used in DTF printing techniques?

DTF printing techniques are highly versatile and can be applied to various materials, including cotton, polyester, blends, and even specialty fabrics like leather and silk, making it suitable for diverse custom textile printing applications.

What impact does DTF print quality have on custom textile printing?

DTF print quality is remarkable, offering vibrant colors and durability that withstand multiple washes. This high print quality is crucial for businesses aiming to provide long-lasting products that meet customer expectations in the custom apparel market.

Is DTF printing environmentally friendly?

Yes, the DTF printing process is increasingly utilizing eco-friendly and water-based inks, making it a sustainable option for custom textile printing. This commitment to sustainability helps brands reduce their environmental footprint while producing high-quality printed products.

| Key Point | Description |

|---|---|

| What is DTF Printing? | A method that transfers designs from a film to textiles using heat, noted for vibrant colors and versatility across materials. |

| Advancements in Technology and Equipment | Utilizes specialized printers and eco-friendly inks that enhance print quality and efficiency. |

| Market Demand and Growth Potential | Growing demand for customized apparel, particularly in sectors emphasizing unique designs. |

| Versatility in Applications | Can print on a wide array of materials, including light and dark fabrics, expanding application scope. |

| User-Friendly Workflow | New designs offer simplified operations, reducing training time and enhancing productivity. |

| Challenges with DTF Printing | Initial investment costs and a learning curve for new operators can pose barriers to entry. |

| Benefits of DTF Printing | Includes high-quality prints, cost-effectiveness for small runs, quick turnaround, and sustainability. |

| Recommendations for Getting Started | Research equipment, invest in training, understand best practices, and build a strong portfolio. |

Summary

DTF printing techniques are revolutionizing the textile printing industry, providing innovative solutions for applying designs to fabric. This advanced method, which transfers vibrant imagery directly from film to a variety of materials, highlights the growing intersection of technology and sustainability. As DTF printing continues to evolve, its ability to produce high-quality, cost-effective, and environmentally friendly prints positions it as a preferred choice for businesses. With its user-friendly systems and versatile applications, anyone exploring custom printing options should consider incorporating DTF printing techniques into their workflow to stay competitive and meet market demands.