Cost-effective printing is a crucial consideration for businesses looking to optimize their production while maintaining high standards. As companies strive to balance quality and budgets, innovative methods like DTF transfers are rising above traditional techniques. Unlike screen printing, which often incurs hefty setup costs, DTF printing allows for greater efficiency, especially with smaller orders. This method not only enhances printing efficiency but also improves color quality in printing, ensuring vibrant results without breaking the bank. In this article, we will explore the transformative advantages of DTF over conventional printing methods, emphasizing its versatile applications and cost-saving potential.

When we talk about affordable printing solutions, we often encounter various terms synonymous with cost-effective printing, such as budget-friendly printing methods or economical print solutions. The emergence of alternatives like digital transfers and modern inkjet techniques has revolutionized how businesses approach their printing needs. These innovative methods focus on enhancing operational efficiency, reducing waste, and offering superior color reproduction, catering to the demands of the contemporary market. By understanding these versatile print methods, companies can make informed decisions that align their practices with economic realities and consumer expectations. This discussion will highlight the myriad benefits of adopting alternative printing technologies in the pursuit of excellence.

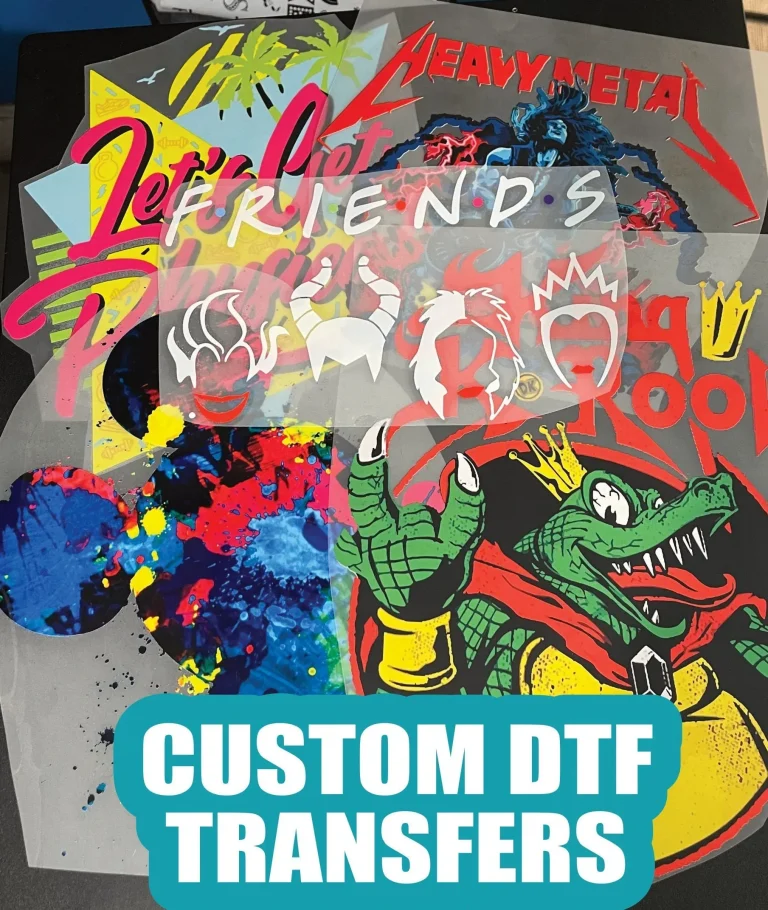

Understanding DTF Transfers vs. Screen Printing

In the realm of custom printing, a fundamental choice that businesses face is between Direct to Film (DTF) transfers and traditional screen printing. DTF transfers are a new and advanced method that enables high-quality images to be printed directly onto a special film, which is then transferred onto the desired material using heat. This technique brings with it a range of advantages, particularly in terms of flexibility and ease of use. Unlike screen printing, which often requires separate screens for each color in a design, DTF can achieve complex designs in a single go, allowing for better integration of detailed graphics and consistent color saturation.

Screen printing has long been a staple in the printing industry, favored for its longevity and vibrancy; however, it faces significant challenges concerning setup time and costs, especially for smaller orders. With the requirement for screen preparation and a minimum quantity of items to produce efficiently, many businesses find themselves limited. DTF transfers, on the other hand, change this dynamic, providing businesses with an optimal solution that combines efficiency, lower costs, and the capability to produce high-quality prints on a variety of fabrics—all crucial elements for modern-day printing needs.

The Cost-Effective Benefits of DTF Transfers

Cost-effective printing solutions are a significant concern for many businesses, especially startups and small enterprises. DTF transfers shine in this area, offering substantial cost savings compared to the often prohibitive setup costs associated with screen printing. With DTF, the framework is streamlined, meaning that businesses can take on small and medium-sized orders without the financial burden of preparing multiple screens or managing extensive material inventories.

Furthermore, the cost-effectiveness of DTF isn’t solely about initial savings; it also extends to the operational advantages that come with reduced labor and material waste. The ease of printing allows businesses to experiment with designs without the fear of severe financial implications. This flexibility translates into a more profitable bottom line, empowering businesses to concentrate on sales and customer satisfaction instead of being bogged down by production challenges inherent to traditional printing methods.

Enhancing Color Quality in DTF Printing

Color quality is often a critical consideration for businesses in the competitive printing arena. DTF transfers provide an exceptional palette of colors that vibrantly capture intricate designs. Unlike screen printing, which can struggle to create detailed images with complex color blends efficiently, DTF technology utilizes advanced ink formulations that yield crisp lines and rich, vivid colors. This formulation ensures that every design is rendered with precision, showcasing the true potential of high-quality graphics.

The ability to produce lifelike reproductions and gradients sets DTF apart in the visual impact it offers brands. This superior color quality not only enhances the aesthetic appeal of products but also elevates brand perception in crowded marketplaces. Companies that prioritize high-definition graphics and intricate designs will find that DTF transfers excel in delivering pieces that stand out and resonate with their audience.

Versatile Print Methods with DTF

Flexibility is key in today’s ever-evolving market, and DTF transfers exemplify this versatility by accommodating a wide range of materials. From cotton and polyester to more unique substrates like nylon and leather, the adaptability of DTF is a game-changer. This capability allows businesses to diversify their product offerings and appeal to various customer demographics by catering to trends and specific market needs without being confined to standard fabric limitations.

Moreover, this versatility in print methods enhances the creativity that businesses can integrate into their product lines. Whether it’s seasonal styles, custom orders, or unique personalized items, DTF technology facilitates the production of diverse merchandise, thus enabling brands to engage their customers in innovative ways. This adaptability not only fosters increased customer satisfaction but also drives sales opportunities, making it a useful asset for contemporary businesses.

Boosting Production Efficiency with DTF

With production efficiency being a key concern for businesses, DTF transfers simplify the process through an accelerated operation. By eliminating the multiply set-up requirements of screen printing, businesses can streamline their workflow, thus dramatically reducing turnaround times. The straightforward steps involved in DTF—printing designs onto film and transferring them with heat—allow for quicker processing while maintaining high quality, effectively aligning production outcomes with market demands.

As a result, businesses can respond more swiftly to orders and customer needs, boosting overall productivity and enhancing customer satisfaction. Faster production cycles not only improve cash flow but also position businesses to capitalize on time-sensitive opportunities in the marketplace, giving them a competitive edge over those still reliant on more traditional methods.

Sustainable Printing Practices Through DTF

In a world increasingly focused on sustainability, the environmental impact of printing processes has come under scrutiny. DTF transfers provide a strong solution in this regard, making use of water-based inks that have a considerably lower environmental footprint compared to the solvent-based inks utilized in conventional screen printing. This choice aligns with growing consumer desires for eco-friendly products, allowing brands to market themselves boldly as responsible manufacturers.

Moreover, the reduction of waste in DTF printing further supports a business’s ecological practices. Since DTF can print intricate designs with less need for setup materials like screens, there is a significant decrease in resource consumption. By adopting DTF technology, companies not only enhance their print quality but also actively contribute to a healthier planet, resonating with environmentally-conscious consumers and paving the way for a more sustainable business model.

Frequently Asked Questions

What are DTF transfers and how do they contribute to cost-effective printing?

DTF transfers, or Direct to Film transfers, offer a cost-effective printing solution by eliminating the high setup costs associated with traditional screen printing methods. DTF technology allows for high-quality prints on small to medium-sized runs without the need for extensive preparation, making it ideal for businesses seeking budget-friendly options.

How does DTF printing improve printing efficiency compared to screen printing?

DTF printing enhances printing efficiency by simplifying the production process. Unlike screen printing, which requires labor-intensive setup and preparation for each design, DTF allows for quick designs to be printed, drastically reducing turnaround times and enabling businesses to meet customer demands faster.

What are the advantages of DTF transfers in terms of color quality in printing?

DTF transfers are known for their superior color quality in printing. They utilize advanced inkjet printing technology, which renders vibrant colors and fine details, making them suitable for intricate multi-color designs that screen printing often struggles to achieve.

Can DTF transfers be used on a variety of materials for cost-effective printing applications?

Yes, DTF transfers are versatile and can be used on a variety of materials, including cotton, polyester blends, nylon, and even leather. This flexibility allows businesses to expand their product offerings cost-effectively while catering to diverse customer preferences.

Is DTF printing a more environmentally friendly option compared to traditional screen printing?

DTF printing is generally considered more environmentally friendly, as many DTF inks are water-based and contain lower levels of harmful solvents compared to traditional screen printing inks. This eco-conscious approach supports a company’s commitment to sustainable practices without sacrificing print quality.

How can businesses benefit from cost-effective printing using DTF technology?

Businesses can benefit from cost-effective printing using DTF technology by minimizing upfront costs, reducing production times, and enhancing the quality of their prints. This enables them to innovate their product offerings while maintaining profitability and responding swiftly to market demands.

| Key Aspect | DTF Transfers | Screen Printing |

|---|---|---|

| Cost Efficiency | High cost efficiency for small to medium orders; low overhead costs | High setup costs and preparation times associated with smaller runs |

| Versatility in Applications | Prints on various materials (cotton, polyester, nylon, leather) | Limitations with certain materials; less adaptable to diverse products |

| Color Quality and Detail | Exceptional color vibrancy and detail, ideal for intricate designs | Often compromised detail and color gradients, limiting design complexity |

| Production Simplification | Simpler process reduces errors and improves turnaround times | Labor-intensive preparation process slows down production |

| Environmentally Friendly Printing | Utilizes water-based inks; lower environmental impact | Inks may contain harmful solvents; higher environmental footprint |

Summary

Cost-Effective Printing has emerged as a crucial consideration for businesses seeking to optimize their printing processes. The advantages of Direct to Film (DTF) transfers over traditional screen printing highlight a significant shift in how companies can efficiently meet customer demands without incurring high costs. DTF provides unparalleled cost efficiency, allowing small and medium-sized orders to thrive without the financial strain imposed by screen printing’s setup and production costs. In addition, DTF promotes versatility across diverse materials, superior color quality, and simplified production, making it a powerful tool for companies aiming to innovate their product lines. As businesses navigate an increasingly competitive landscape, embracing DTF technology not only fulfills operational goals but also aligns with the growing consumer preference for sustainability in printing practices. Ultimately, for those pursuing affordable and high-quality printing solutions, DTF transfers present an ideal pathway toward achieving these objectives.