DTF printing, short for Direct-to-Film printing, is revolutionizing the textile printing landscape with its ability to produce stunning and durable designs. This innovative method delivers vibrant colors and intricate details, making it an ideal choice for custom apparel creation. Whether you are a DIY enthusiast aiming to personalize fabric items for loved ones or a business owner looking to enhance your product offerings, mastering the DTF printing process is crucial. Through this guide, we will uncover the advantages of DTF printing technology, explore the steps involved, and offer valuable insights for beginners. Embrace the future of printing and discover how DTF can elevate your creative projects!

Known as Direct-to-Film, this printing method has garnered attention for its efficiency and quality. The DTF printing technique involves transferring designs from a specially coated film onto various fabrics, providing versatility and vibrant outcomes. As businesses and creators alike turn to advanced printing solutions, understanding the DTF process becomes essential for maximizing creativity and functionality. From novice to expert, exploring the advantages of this technology opens new avenues for producing customized clothing. Join us as we delve into the intricacies of DTF printing and its impactful role in modern textile applications.

Understanding the Basics of DTF Printing

Direct-to-Film (DTF) printing is an innovative textile printing method that enables artists and businesses to create stunning, high-quality garment designs. In this process, the design is printed onto a specially coated film, which allows for a more vivid representation of colors and details compared to traditional printing methods. The DTF printing process is particularly beneficial because it caters to various materials, including cotton, polyester, and blends, ensuring versatility in the apparel market. Furthermore, the ability to print detailed designs on-demand supports the growing trend of customization in fashion.

For individuals entering the world of DTF printing, it’s crucial to understand how this process differs from others like Direct-to-Garment (DTG) printing or screen printing. Unlike screen printing, which requires multiple screens for various colors and can be limited by production speed, DTF printing allows for multiple colors within a single print run. This adaptability is essential for small businesses or hobbyists who desire unique products without significant investment in multiple printing techniques.

The DTF Printing Process Explained

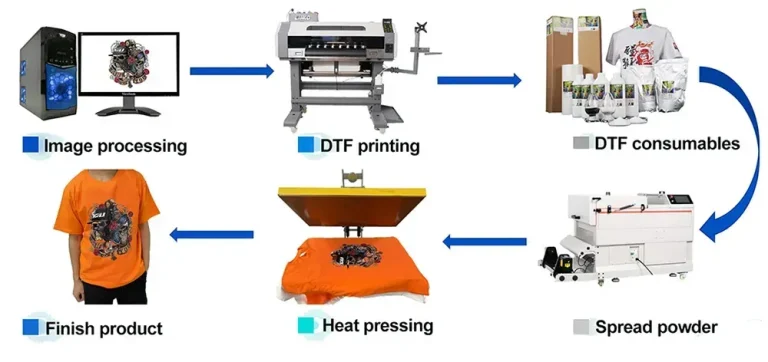

The DTF printing process involves several meticulous steps to ensure high-quality results. Initially, it starts with design creation using graphic software, so individuals must be proficient in design tools to craft compelling visuals. Once the design is ready, it is printed onto a film using a specialized DTF printer that is calibrated for color accuracy and detail. After printing, an adhesive powder is sprinkled onto the wet ink, which is crucial for the transfer process, making this step essential to achieving a lasting bond between the design and fabric.

Following the application of the adhesive, the printed film undergoes curing, typically through heating elements, allowing the adhesive to melt and adhere properly. The final stage of the DTF process is pressing the film onto the garment using a heat press, where the heat activates the adhesive’s properties, allowing the design to transfer securely onto the fabric. This multi-step approach to DTF printing enhances the durability and vibrancy of the end product, making it a favored choice among professionals.

Benefits of DTF Printing for Custom Apparel

DTF printing offers numerous advantages that make it particularly attractive for custom apparel creation. One of the most significant benefits is versatility; this technique can print on various fabric types without compromising quality, making it suitable for everything from t-shirts to hoodies and even accessories. Moreover, the cost-effectiveness of DTF printing shines in short runs, where businesses can minimize waste and maximize profits without the need for extensive inventories. This aspect is especially beneficial for small businesses catering to niche markets.

Another critical advantage is the high-quality output that DTF printing provides. Unlike some traditional methods, DTF prints deliver vibrant colors and intricate details that catch the eye. The soft finish of the prints enhances the wearability of items, making them comfortable while maintaining durability. This is particularly significant in fashion, where both aesthetic and comfort factors influence customer satisfaction.

Challenges and Disadvantages of DTF Printing

While DTF printing has numerous advantages, it is not without its challenges. One primary concern is the initial investment required to purchase DTF printers and corresponding equipment. This cost can deter new businesses or individuals starting in the custom printing industry. Additionally, potential users should be aware that there is a learning curve to operating DTF printers. Understanding the intricacies of settings, temperature requirements, and adhesive applications is vital to producing high-quality prints consistently.

Another consideration is the speed limitations of DTF printing compared to other popular methods like screen printing. For larger orders or bulk production, screen printing may offer a faster turnaround time. However, for short-run jobs and personalized items, DTF printing’s adaptable nature may offset this speed disadvantage. Ultimately, weighing these challenges against the benefits is essential for anyone looking to invest in DTF printing technology.

Latest Innovations in DTF Printing Technology

The realm of DTF printing technology is continuously advancing, with recent innovations driving its popularity and improving efficiency. As manufacturers introduce faster printers with enhanced features, the ability to produce high-quality prints has seen marked improvements. These technological advancements not only streamline the DTF printing process but also expand the possibilities for intricate designs and vibrant colors.

Additionally, there has been notable progress in the quality of inks used in DTF printing, resulting in longer-lasting and more resilient prints. The development of eco-friendly inks is also gaining traction, appealing to environmentally conscious consumers and businesses. With the rapid increase in e-commerce and personalized products, the DTF printing market is poised for significant growth, reflecting the technology’s adaptability and customer’s preference for customization.

Getting Started with DTF Printing: A Beginner’s Guide

For those interested in exploring the world of DTF printing, getting started can seem daunting but is highly rewarding. Beginners should begin by familiarizing themselves with the essential equipment needed, including DTF printers, heat presses, and suitable inks and films. Many educational resources and tutorials are available online, providing users with valuable insights and tips on design software and the DTF printing process.

Moreover, experimenting with small projects can build confidence and mastery over the equipment. Many beginners create sample garments before taking on larger, more complex orders. Participating in online forums or local printing communities can also offer support and advice to new entrants, making it easier to navigate the challenges of DTF printing.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct-to-Film printing, is a cutting-edge textile printing technique that involves printing designs onto a special film. The printed film is then transferred onto the fabric using heat and pressure. This process utilizes DTF inks and PET film to ensure vibrant colors and high detail in designs, making it a popular choice for custom garment creation.

What are the advantages of DTF printing over other methods?

The advantages of DTF printing include its versatility to print on various materials like cotton and polyester, cost-effectiveness for short runs, and the ability to produce high-quality, detailed prints. Additionally, DTF prints have a soft finish, providing comfort without sacrificing durability, making it a preferred choice for custom apparel.

Is DTF printing suitable for beginners?

Yes, DTF printing is suitable for beginners, though there is a learning curve involved. Starting out, users should familiarize themselves with graphic design software, the DTF printing process, and the operation of DTF printers. With practice and guidance, beginners can quickly achieve excellent results and enjoy the benefits of this printing technology.

What kind of materials can be used with the DTF printing process?

DTF printing is highly versatile and can be used on a variety of materials, including cotton, polyester, blends, and even some synthetic fabrics. This capability allows users to create vibrant and long-lasting designs on a wide range of garments, making it an ideal choice for custom printing projects.

What are the initial costs associated with DTF printing?

The initial costs of setting up for DTF printing can be high, as it requires investing in specialized DTF printers, inks, and essential equipment. However, this investment can pay off for businesses dealing with custom orders by minimizing waste and maximizing profits, thanks to its efficiency in handling short runs.

What recent advancements have been made in DTF printing technology?

Recent advancements in DTF printing technology include the development of faster printers that deliver higher quality prints, improved DTF inks, and better adhesives. These innovations enhance the overall efficiency and quality of the DTF printing process, making it more appealing for both hobbyists and commercial operations.

| Key Aspects | Details |

|---|---|

| Introduction to DTF Printing | A revolutionary textile printing technique offering high-quality, vibrant, and durable prints for apparel. |

| What is DTF Printing? | Involves printing designs on special film and transferring them to fabric using heat. |

| Advantages | Versatile on multiple materials, cost-effective for short runs, high-quality with color-rich prints, and soft finish. |

| Disadvantages | High initial costs, speed limitations compared to screen printing, and a learning curve for new users. |

| Latest Developments | Innovative equipment is improving speed and quality, with a growing market due to demand for customization. |

Summary

DTF printing is reshaping the landscape of textile printing, providing an innovative method for creating custom apparel. With its capacity for vibrant, high-quality designs, DTF printing is becoming a popular choice among businesses and hobbyists alike. Understanding the DTF printing process—from design creation to heat pressing—is crucial for anyone looking to engage with this technology. While it presents some initial cost and learning curve challenges, the benefits of versatility, print quality, and compatibility with various materials make DTF printing a formidable option in the printing industry.