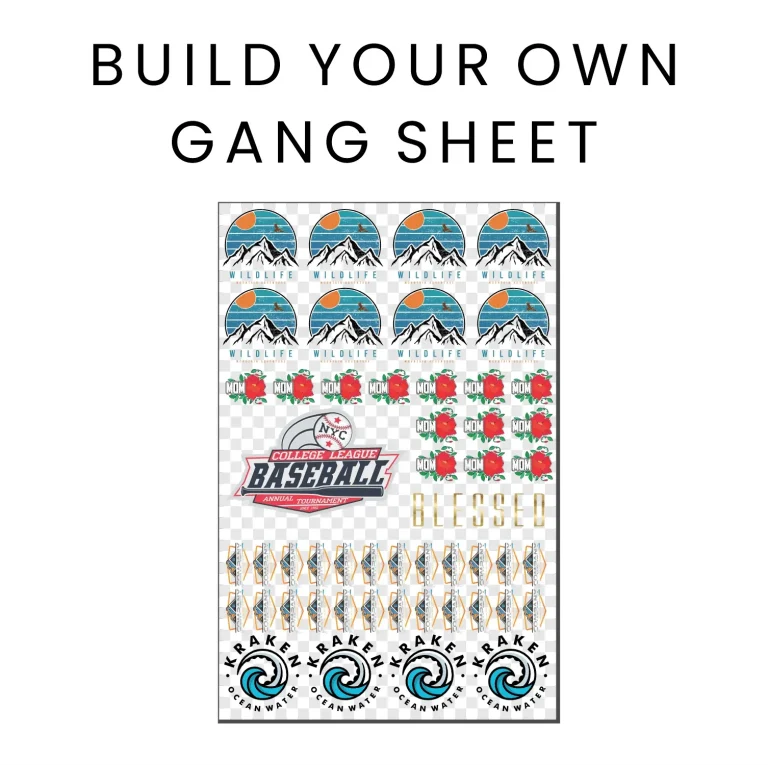

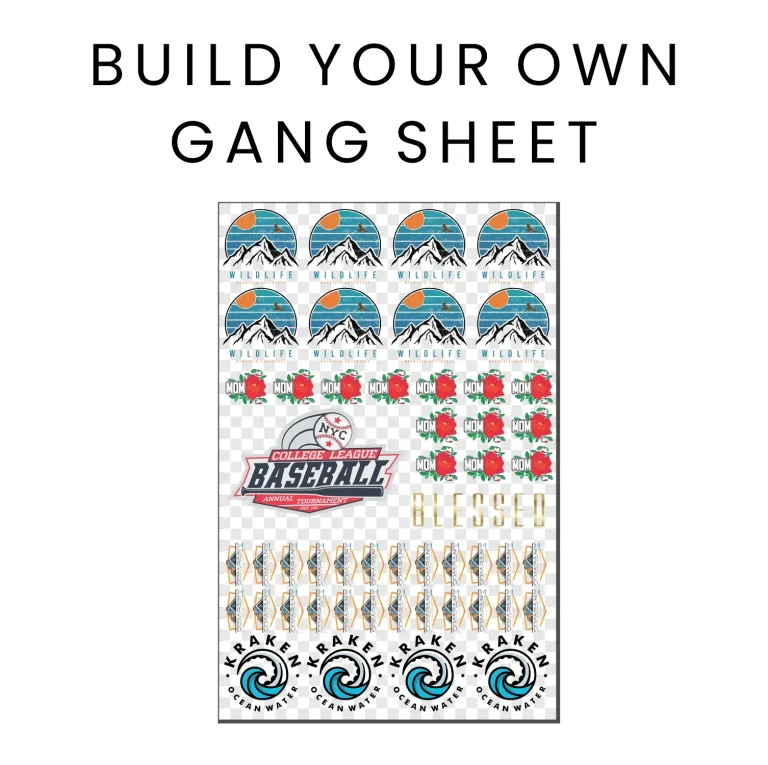

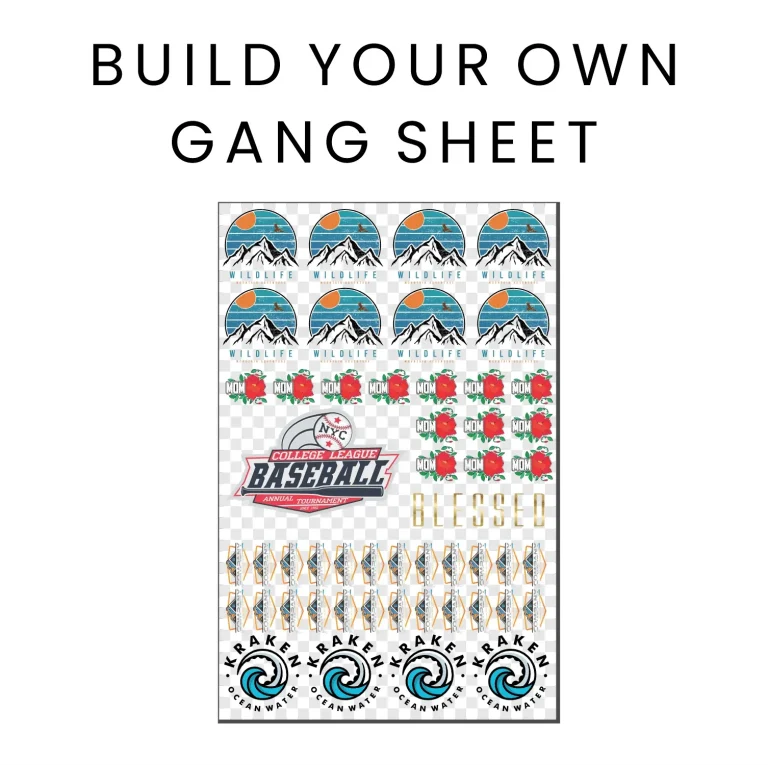

In the fast-paced world of garment printing, the DTF Gangsheet Builder stands out as a revolutionary tool for enhancing printing efficiency. As Direct-to-Film (DTF) printing grows in popularity due to its vibrant results and versatility, utilizing gangsheet printing methods has become essential for maximizing output. This innovative approach enables users to print multiple designs on a single film sheet, thereby reducing material waste and lowering costs. By integrating effective printing software for DTF with smart design strategies, businesses can optimize their DTF workflow like never before. Join us as we dive deeper into how to harness the full potential of a DTF Gangsheet Builder to elevate your printing operation.

Exploring the realm of DTF printing, one often encounters terms like gangsheet production and Direct-to-Film techniques, which emphasize efficiency in the printing process. The DTF Gangsheet Builder, a specialized software solution, significantly enhances workflow by allowing multiple designs to be printed on a single sheet simultaneously. This method not only streamlines the printing operation but also conserves resources, making it a favorable choice for businesses looking to maximize their output. By adopting this cutting-edge approach to garment printing, users can achieve impressive results while keeping costs manageable. Understanding the nuances of gangsheet creation and DTF practices can pave the way for a more productive printing environment.

Maximizing DTF Printing Efficiency with Gangsheet Techniques

Direct-to-Film (DTF) printing has revolutionized how we approach garment customization by allowing the efficient transfer of vibrant patterns directly onto fabrics. At the heart of optimizing DTF printing efficiency lies the gangsheet technique, which permits the simultaneous printing of multiple designs on a single film sheet. This approach not only significantly reduces print time but also conserves material, promoting a more cost-effective printing process. Understanding the nuances of gangsheet printing is essential for anyone looking to streamline their DTF operations and enhance productivity.

By adopting an effective gangsheet strategy, print businesses can reduce waste and make the most out of their resources. Aligning designs to maximize the sheet’s use directly impacts both production speed and cost-efficiency. Additionally, using high-quality DTF materials, including specialized inks and films, ensures that printed designs maintain their vibrancy and quality. This combination of efficient design placement and superior materials lays the foundation for a successful DTF operation.

Choosing Software for Optimal DTF Workflow

The right software selection can make or break your DTF gangsheet printing workflow. When assessing software options, it’s vital to consider those specifically optimized for DTF printing. Software designed for gangsheet creations often features intuitive design tools that enable easy adjustments and rearrangements of artwork on the film. Such functionalities not only save time but also enhance the precision of layout, ensuring every inch of the film is utilized effectively. Popular choices like Adobe Illustrator and CorelDRAW are renowned for their capabilities, but dedicated DTF printing software can elevate the experience further with specialized features.

To truly optimize your DTF workflow, ensure your chosen printing software integrates well with your hardware, supporting updated printer specifications and settings. Look for tools that offer advanced features such as design previews, color management, and easy resizing, which can be critical in scrupulously preparing designs. By leveraging the right software, businesses can enhance both operational speed and printing quality, ensuring a superior end product for customers.

Key Design Considerations for DTF Printing

Design considerations play a pivotal role in achieving optimal results in DTF gangsheet printing. One of the primary aspects to focus on is color management, which must align with the capabilities of the specific DTF printer in use. Consistent color palettes and preparing artwork according to the printer’s ink profile help prevent discrepancies in final prints. Additionally, establishing clear guidelines for spacing and alignment is crucial. Properly arranged designs minimize risks of overlap or ink bleed, which can detract from the overall quality of the printed material.

Moreover, utilizing design software with grid and guideline features allows for precise alignment of elements within gangshets. This strategic planning not only results in improved aesthetics but also enhances production efficiency by reducing the necessity for reprints due to design flaws. Therefore, investing time in thoughtful design considerations can yield significant payoffs, both in productivity and in achieving high-quality prints that satisfy customer expectations.

The Importance of Quality Materials in DTF Printing

The selection of materials used in DTF printing is foundational to achieving superior print quality. Premium-quality transfer films and inks are critical to ensuring vibrant, long-lasting prints. Using subpar materials can often lead to common issues such as poor adhesion, muted colors, and a lack of durability in the printed designs. Investing in high-quality supplies not only reduces the likelihood of unfavorable outcomes but also enhances the overall printing process, leading to a more seamless production experience.

Additionally, optimizing printer settings is equally important when transitioning to DTF printing materials. Each film and ink type may necessitate unique printer configurations for optimal performance. Regularly calibrating printer settings and running test prints can ensure that the equipment consistently delivers the best results. By prioritizing the quality of materials and adjustments to printer settings, businesses can significantly improve their output quality and efficiency.

Strategies for Effective Batch Processing in DTF Printing

Batch processing is a technique that can significantly amplify DTF printing productivity. By organizing multiple gangsheet prints to be executed concurrently, businesses can optimize printer usage and minimize downtime caused by individual print jobs. This forward-thinking approach not only accelerates the fulfillment of orders but also promotes an efficient workflow that takes advantage of the printer’s capabilities.

Managing time effectively during batch processing is also essential. Implementing a systematic schedule for printing can help maintain consistent output rates while allowing for quick identification of any bottlenecks in the production line. By harnessing the power of batch processing, print shops can meet high demand periods without sacrificing the quality of their work or the speed of delivery to customers.

Continuous Training and Industry Engagement for DTF Success

Training personnel on the proper use of DTF gangsheet builders is crucial for maintaining high levels of efficiency in production operations. Regular training sessions keep staff informed about the latest software updates, design techniques, and manufacturing processes, which can positively impact overall productivity. Ensuring that all team members are competent in using the machinery will help reduce delays caused by operational errors and enhance the quality of the prints produced.

Moreover, staying engaged with industry developments through workshops, trade shows, and online forums can significantly benefit businesses involved in DTF printing. Keeping up-to-date with the latest trends and technologies in this fast-paced market allows for the adaptation and incorporation of new methods that can further optimize printing processes. By investing in personnel training and industry engagement, businesses not only improve efficiency but also position themselves for sustained growth in a competitive landscape.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it enhance DTF printing efficiency?

The DTF Gangsheet Builder is a specialized software tool designed for gangsheet printing in Direct-to-Film (DTF) printing. It optimizes efficiency by allowing users to arrange multiple designs on a single film sheet, reducing material waste and production time. This method streamlines the printing process, enabling quicker turnaround times and maximizing output quality.

How can I choose the right printing software for my DTF Gangsheet Builder?

When selecting software for your DTF Gangsheet Builder, prioritize tools that offer features like easy design resizing, alignment grids, and automated layout optimization. Popular options include Adobe Illustrator and specialized DTF printing software that can enhance efficiency by minimizing manual adjustments and ensuring optimal placement of designs.

What design considerations should I keep in mind when using a DTF Gangsheet Builder?

Key design considerations for maximizing efficiency with a DTF Gangsheet Builder include maintaining consistent color management, proper spacing between designs to prevent overlap, and utilizing alignment tools available in your printing software. These factors ensure high-quality outputs while reducing the risk of printing errors.

Why is the quality of materials important in DTF gangsheet printing?

High-quality materials, including transfer films and inks, are crucial in DTF gangsheet printing because they directly impact print adhesion and vibrancy. Using subpar materials may result in designs that fade or peel, leading to customer dissatisfaction and increased waste. Investing in premium supplies enhances overall production quality.

How does batch processing improve efficiency in DTF gangsheet printing?

Batch processing, which involves printing several gangsheet designs at once, significantly improves efficiency in DTF printing. This strategy minimizes printer downtime and allows for higher productivity by effectively streamlining workflow, enabling you to fulfill multiple orders simultaneously.

What training is essential for staff using the DTF Gangsheet Builder?

Comprehensive training for staff operating the DTF Gangsheet Builder is essential to maximize efficiency. This includes familiarizing them with printing software, equipment operation, and best practices in design layout. Regular training sessions keep team members updated on industry trends and technological advancements, thereby ensuring high-quality outputs.

| Key Aspect | Explanation |

|---|---|

| Understanding Gangsheet Printing | Gangsheet printing places multiple designs on a single sheet, saving time and reducing costs. |

| Choosing the Right Software | Select software like Adobe Illustrator or DTF-specific tools that automate layout tasks for maximum efficiency. |

| Design Considerations | Focus on color management and spacing to avoid poor-quality prints and enhance accuracy. |

| Quality of Materials | Invest in high-quality transfer films and inks; optimize printer settings for the best results. |

| Batch Processing | Print multiple gangsheet designs at once to reduce downtime and improve productivity. |

| Training and Familiarization | Ensure staff is trained to use the DTF gangsheet builder effectively, keeping production quality high. |

| Keep Up with Industry Trends | Stay informed about DTF printing advancements through online communities and professional events. |

Summary

The DTF Gangsheet Builder is an indispensable tool in streamlining garment printing processes and enhancing productivity. By understanding key elements such as software selection, design considerations, and the quality of materials, businesses can optimize their workflow for maximum output. Emphasizing efficient design techniques paired with effective batch processing, along with proper staff training and staying updated with industry trends, are all critical for achieving success in the ever-competitive DTF printing market. Embracing these strategies not only elevates quality and efficiency but also fosters customer satisfaction that is crucial for any thriving business.