DTF Supplies are essential for anyone looking to venture into the dynamic world of Direct-to-Film (DTF) printing. With its ability to deliver high-quality, vibrant prints on a variety of fabrics, DTF printing is rapidly becoming a favorite among custom apparel businesses and DIY enthusiasts alike. This unique printing method combines advanced technology with creativity, allowing users to transfer detailed designs onto garments effortlessly. In this guide, we’ll delve into the must-have DTF printing supplies, including specialized DTF printers, high-quality inks, and transfer films necessary for achieving impressive results. Whether you’re a seasoned professional or just starting out, having the right DTF supplies is crucial for maximizing your printing potential and ensuring customer satisfaction.

When discussing the essentials of DTF printing, one might encounter terms like Direct-to-Film materials, which refer to the specific items necessary for successful fabric printing. This innovative printing process utilizes specially formulated inks and films to create stunning designs that seamlessly adhere to various textiles. The DTF printing supplies required, such as a reliable DTF printer and high-quality adhesive powders, play a pivotal role in achieving optimal results. Understanding these components will enhance your ability to produce superb prints for the fashion industry or personal projects. The landscape of DTF printing is vast, and being equipped with the best materials is key to unlocking your creative potential.

Understanding Direct-to-Film Printing

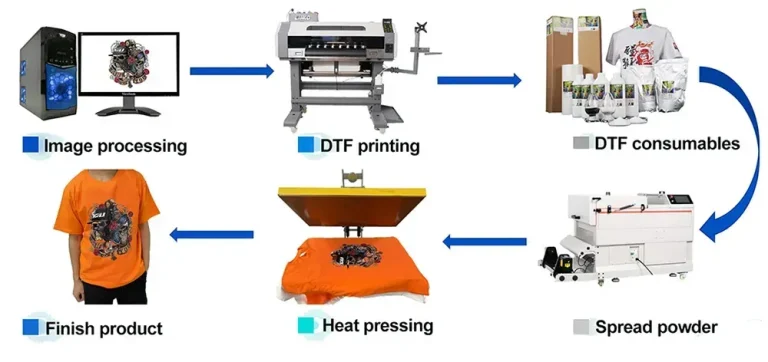

Direct-to-Film (DTF) printing is redefining the landscape of garment customization. This innovative method allows users to print intricate and vibrant designs directly onto a film, which can then be applied to various fabrics including cotton, polyester, and blends. One of the primary advantages of DTF printing is its ability to reproduce highly detailed graphics that traditional screen printing often struggles with. Setting itself apart, DTF printing utilizes a unique ink transfer method that ensures vivid colors and sharp edges, enabling creative expressions on clothing that are both stunning and long-lasting.

Moreover, DTF printing supports a wide range of applications beyond apparel. From custom home decor to promotional materials, it’s gaining traction in various industries. The versatility of DTF printing can satisfy diverse commercial needs, making it an appealing choice for businesses that want to expand their product lines. As the technique advances, it continues to attract attention for its potential to reduce waste and enhance efficiency, aligning with modern sustainable practices.

Essential DTF Supplies for Successful Printing

To achieve optimal results in DTF printing, investing in the right supplies is crucial. The key components include a specialized DTF printer, quality inks, and proper transfer films. Brands like Epson and Roland offer exceptional DTF printers designed specifically for handling the high-resolution images needed for vibrant prints. Utilizing specially formulated DTF inks ensures not only vivid colors but also the longevity of printed designs, making them resilient against fading and washing.

In addition to printers and inks, the choice of transfer films and adhesive powders plays a significant role in the overall quality of the prints. Films made from high-quality polyethylene terephthalate (PET) offer great adhesion characteristics and clarity in transfers. Coupled with the right adhesive powder, these materials create robust designs that stick well during the transfer process, resulting in professional-grade apparel that can stand the test of time.

Exploring the DTF Printer Options

When it comes to choosing a DTF printer, the market offers several options that cater to various production needs. Printers specifically designed for DTF tasks provide features such as high-speed printing capabilities and precision color management. Models like the Epson SureColor series are notable for their efficiency and reliability, perfect for both small businesses and large-scale operations. Selecting the right printer involves considering factors like print resolution, speed, and compatibility with DTF inks.

In addition to standard functionalities, many DTF printers come equipped with advanced technology that allows for better ink distribution and fewer clogs. This can lead to higher print quality and significantly lower maintenance costs in the long run. As competition and customer expectations rise, investing in a high-quality DTF printer can be the key to staying ahead in the custom apparel market.

Choosing the Best DTF Inks

The selection of DTF ink can greatly influence the quality of your prints. High-grade DTF inks are engineered to bond effectively with transfer films and fabrics, ensuring that designs remain vibrant and true to color. Where lower-quality inks may lead to issues like washing out or cracking, premium options maintain their quality and depth even after repeated washes. Look for inks that boast a wide color gamut and high opacity for the best results.

Additionally, eco-friendly DTF inks are becoming more available, catering to the rising demand for sustainable printing solutions. These inks not only minimize the environmental impact but also appeal to a growing market of consumers seeking responsible products. Staying updated on the latest developments in DTF inks can help ensure that your business remains competitive in an ever-evolving industry.

The Importance of Quality DTF Transfer Film

Quality transfer film is another integral component of the DTF printing process. The right film will facilitate effective ink adhesion and transfer, crucial for achieving prints that are both vibrant and durable. Transfer films are typically available in various coatings, each designed to offer unique benefits depending on your specific project needs. When choosing a transfer film, consider factors such as compatibility with your DTF printer and ink, as well as its durability after heat pressing.

Investing in high-quality transfer film can prevent common printing issues such as peeling or fading, resulting in a better final product. Furthermore, as innovation continues, new types of transfer films are emerging that promise improved functionality and ease of use. Always research customer reviews and product specifications before making a purchase to ensure optimal results in your DTF printing process.

Maintaining Your DTF Printer for Longevity

Regular maintenance is key to extending the lifespan of your DTF printer. This includes routine cleaning of the print heads and using maintenance kits specifically designed for DTF printers. Printing with high-quality DTF inks can also minimize clogging, making upkeep easier and more effective. Keeping a consistent cleaning schedule prevents build-up that can affect print quality and prolongs the life of your machine.

Besides physical maintenance, it’s important to stay educated on the latest techniques and industry best practices. Many DTF printers offer user manuals with specific guidelines on maintenance schedules and troubleshooting tips. Participating in online forums or community groups dedicated to DTF printing can provide additional support and insight into best practices, helping you maintain peak performance from your equipment.

Frequently Asked Questions

What are the essential supplies for Direct-to-Film (DTF) printing?

To start with DTF printing, you’ll need essential supplies such as a specialized DTF printer, high-quality DTF inks, transfer films, adhesive powder, a reliable heat press, and cleaning supplies to maintain your printer’s performance.

How does a DTF printer differ from other types of printers?

A DTF printer is specifically designed for Direct-to-Film printing, allowing for high-resolution images to be printed on specialized films. Unlike standard inkjet or laser printers, DTF printers use unique DTF inks that bond well with the films and fabrics during the transfer process.

What type of DTF inks should I use for the best results?

For optimal results in DTF printing, it’s essential to use high-quality DTF inks that are formulated to bond with the transfer film. These inks ensure vibrant colors and durability against washing, helping your prints last longer.

How important is choosing the right transfer film for DTF printing?

Choosing the right transfer film is crucial in DTF printing as it directly affects adhesion and print clarity. High-quality films designed for DTF applications ensure that your prints transfer accurately and maintain vibrancy on the garment.

What role does adhesive powder play in DTF printing?

Adhesive powder is applied over the wet ink on the DTF transfer film, forming a bond between the film and the fabric during the heat transfer process. Selecting the right adhesive powder is important for a solid transfer that lasts.

What maintenance is required for a DTF printer?

Regular maintenance for a DTF printer includes cleaning the printer heads with specialized cleaning cartridges and keeping the printer free of dust and debris. This prevents clogging issues and ensures that your prints remain sharp and vibrant.

| Key DTF Supplies | Description |

|---|---|

| DTF Printer | A specialized printer for printing designs on transfer films, often from brands like Epson or Roland. |

| DTF Inks | High-quality inks that produce vibrant and durable prints, essential for successful transfers. |

| Transfer Film | Coated films that accept ink for transferring designs onto fabrics; crucial for print clarity. |

| Adhesive Powder | Powder applied over wet ink to bond designs to fabrics during the heat transfer. |

| Heat Press | A device for applying heat and pressure, critical for solid transfers. |

| Cleaning Supplies | Maintenance tools to clean printer heads and ensure consistent print quality. |

Summary

DTF Supplies are essential for anyone looking to excel in Direct-to-Film printing. This innovative printing method offers unparalleled print quality and versatility, allowing designers to bring their visions to life on various fabrics. Armed with essential DTF supplies—like specialized printers, high-quality inks, and transfer films—creators can achieve stunning results that endure the test of time. Continuous advancements in technology and eco-friendly options also enhance the appeal of DTF printing in today’s market. By understanding the critical items needed and staying informed on current trends, entrepreneurs can position themselves effectively in the booming DTF sector.