DTF transfers, or Direct-to-Film transfers, are revolutionizing the world of custom apparel printing, offering an innovative alternative to traditional techniques. This advanced printing method utilizes a unique process where designs are printed onto a specially coated film, resulting in vibrant, high-quality graphics that adhere seamlessly to various fabrics. One of the major DTF printing benefits is its durability; once transferred, the prints maintain their color and integrity through numerous washes, making them ideal for custom clothing that stands the test of time. Furthermore, the DTF transfer process is incredibly versatile, allowing for various applications across different materials, from cotton to polyester. As businesses and consumers increasingly prioritize environmentally friendly printing options, DTF technology stands out as a sustainable choice, appealing to a market that values both quality and environmental responsibility.

In the realm of fabric customization, transfers that employ Direct-to-Film (DTF) technology are steadily rising to prominence. Known for their high-resolution detailing and vivid print results, this method leverages a specific film creation process that maximizes both efficiency and quality in apparel printing. Many are turning to this approach due to its cost-effectiveness and durability, which ensure long-lasting and appealing designs that can withstand regular wear and cleaning. As new entrepreneurs and established businesses explore this dynamic field, the demand for these innovative custom prints continues to flourish. Not only are these methods revolutionizing how designs are applied to fabrics, but they also cater to eco-conscious consumers seeking greener options in the world of garment decoration.

Understanding the DTF Transfer Process

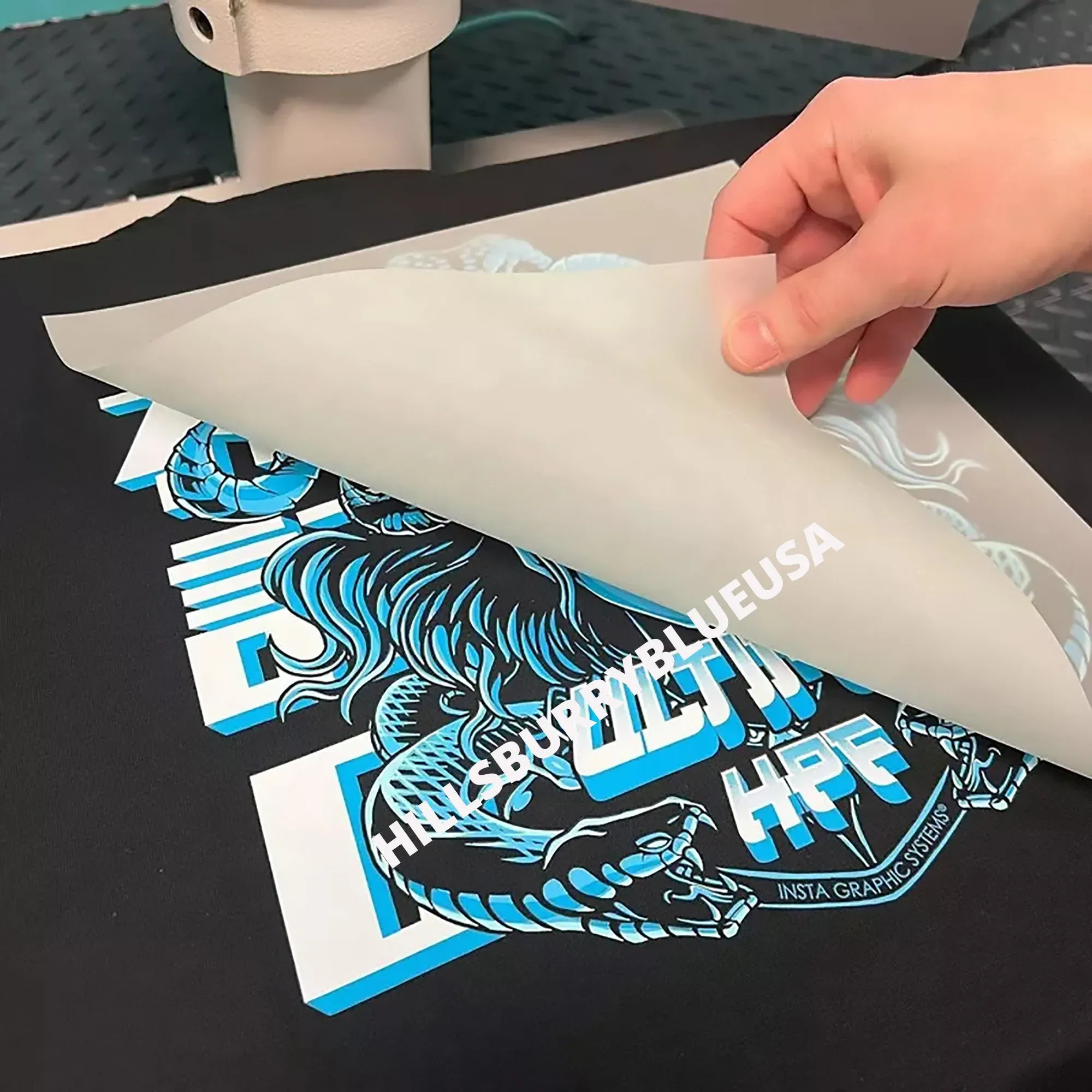

The Direct-to-Film (DTF) transfer process begins with the careful selection of film specifically designed to handle vibrant inks. During this process, the chosen design is printed onto the film using specialized DTF printers that ensure color fidelity and detail. Once the print is finished, an adhesive powder is sprinkled over the design, which is then cured with heat. This crucial step helps the adhesive fuse the ink onto the film, preparing it for the next phase. When heat-pressed onto the final fabric, the adhesive ensures that the design maintains its brilliance and adheres securely, allowing it to withstand washing and usage over time.

This printing method not only offers incredible depth of color and detail but also allows designers the freedom to create intricate patterns that may not be achievable with traditional techniques. The DTF transfer process is particularly renowned for its efficiency, as it requires minimal setup compared to direct printing methods, which often necessitate extensive preparation. This efficiency translates into faster turnaround times for custom apparel, making it a preferred choice for businesses looking to capitalize on trends swiftly.

The Benefits of DTF Printing for Custom Apparel

DTF printing is rapidly becoming the go-to method for custom apparel, thanks to its remarkable benefits. One of the main advantages is the quality it delivers; prints made using this technique exhibit high resolution and vibrant colors. Unlike traditional screen printing, which can suffer from limitations in color blending, DTF allows for a wide spectrum of hues to be applied in a single print session, leading to more complex designs and graphics. This capability makes it possible to cater to diverse customer demands without compromising quality.

Furthermore, DTF printing proves to be exceptionally durable. Garments printed using this method are resistant to wear and machine washing, ensuring that vibrant designs remain intact over time. For businesses in the custom apparel industry, this means higher customer satisfaction and lower return rates due to print quality issues. With the ability to offer both quality and durability, brands can position themselves competitively in the market, appealing to customers who prioritize longevity in their apparel investments.

Environmental Benefits of DTF Printing

As environmental concerns gain prominence among consumers, DTF printing stands out for its sustainable approach. This printing method primarily utilizes water-based inks, which are significantly less harmful to the ecosystem compared to solvent-based inks commonly found in traditional printing techniques. The reduction in hazardous waste produced during the printing process resonates especially with eco-conscious brands and consumers. By choosing to implement DTF technology, businesses can communicate their commitment to sustainability, thus attracting a dedicated clientele that prioritizes ethical practices.

Moreover, the DTF printing process results in less ink waste. Because it allows precise applications directly onto film, less ink is required overall, reducing costs and minimizing environmental impact. Eco-friendly printing isn’t just a trend; it’s becoming a necessity in today’s market, driving companies to adopt technologies that align with their values. Embracing DTF printing not only helps businesses meet consumer demand for sustainable options but also positions them as leaders in environmentally responsible manufacturing.

Market Trends in DTF Printing

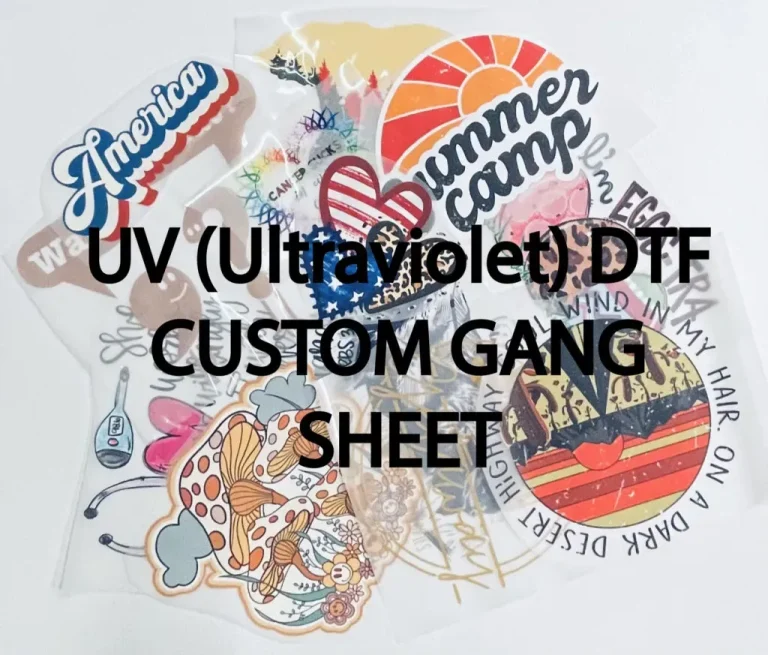

The growing popularity of DTF transfers is distinctly reflected in market trends. With more consumers seeking unique apparel options, businesses are increasingly utilizing DTF technology to meet this demand. The flexibility of this method allows for on-demand production, which is particularly appealing to the e-commerce sector, where personalized items and quick turnaround times can make a significant difference in sales. Insights from industry studies show that small businesses and startups are leveraging DTF printing to create niche products that stand out, capturing the attention of discerning customers.

Additionally, the investment in DTF technology by suppliers and manufacturers is expected to surge as this trend continues. More accessible technology means that entrepreneurs can enter the market easily, fostering creativity and competition. This democratization of printing capabilities has led to a richer product diversity in custom apparel, allowing for innovative designs that cater to various demographics and preferences. As the DTF printing industry expands, businesses must be mindful of adapting to market demands while maintaining quality and environmental standards.

Challenges in Adopting DTF Technology

While the advantages of DTF printing are compelling, it is important for businesses to recognize the challenges associated with its adoption. One significant hurdle is the learning curve that accompanies the new technology. For those unfamiliar with the DTF transfer process, understanding how to prepare films, utilize heat presses, and manage temperature settings can be daunting. Failing to master these aspects can lead to inconsistent results, leaving businesses at risk of damaging their reputations.

Quality control is another challenge that must not be overlooked. The intricacies of the DTF transfer process require meticulous attention to detail; any oversight can result in prints that do not meet consumer expectations. To mitigate these risks, businesses must develop robust quality assurance protocols that ensure every product meets a high standard. By addressing these challenges effectively, companies can harness the full potential of DTF technology while minimizing the risk of errors.

The Future of DTF Transfers in Printing

The future of DTF transfers in the printing industry looks promising as technology continues to advance. With the introduction of new and improved DTF printers and materials, the precision and ease of use are expected to enhance significantly. This evolution will likely attract even more businesses to incorporate DTF technology into their operations, thus enriching the marketplace with innovative apparel options. As DTF continues to dominate the custom printing landscape, it is also predicted to evolve alongside consumer preferences, making it crucial for businesses to stay ahead of emerging trends.

Furthermore, as sustainability becomes an even more pressing concern for consumers, DTF printing will play a vital role in meeting these standards. With ongoing developments aimed at reducing waste and improving eco-friendliness, businesses that adopt DTF technology are well-positioned to optimize their operations for a greener future. Companies that align their practices with these innovative solutions will ultimately benefit from a loyal customer base that values responsibility and quality in their purchasing decisions.

Frequently Asked Questions

What are the main benefits of DTF transfers in custom apparel printing?

DTF transfers offer several key benefits for custom apparel printing, including exceptional quality and durability, versatility across various fabrics, and cost-effectiveness for small production runs. This means businesses can create vibrant, long-lasting designs tailored to their customer’s needs without heavy upfront investments.

How does the DTF transfer process work?

The DTF transfer process involves printing designs onto a specially coated transfer film, which is then coated with adhesive powder and heat-pressed onto fabric. This innovative method enables the production of high-resolution, colorful graphics that adhere effectively to a variety of textile materials.

Is DTF printing environmentally friendly?

Yes, DTF printing is considered more environmentally friendly than traditional printing methods. Many inks used in DTF transfers are water-based, minimizing hazardous waste and promoting sustainability. This eco-conscious approach appeals to modern consumers who prioritize green practices in their purchasing decisions.

Can DTF transfers be used on all types of fabrics?

DTF transfers are highly versatile and can be used on numerous fabric types including cotton, polyester, and blends. This adaptability makes DTF printing ideal for a wide range of applications, from t-shirts to bags and uniforms, without sacrificing quality.

What challenges are associated with the DTF transfer process?

While DTF transfers provide numerous benefits, challenges include a learning curve for newcomers and potential quality control issues if the films are not handled properly. It’s crucial for businesses to ensure consistent quality through careful management of the heat-pressing processes.

What is contributing to the growth of the DTF transfer market?

The growth of the DTF transfer market is driven by increasing consumer demand for customized apparel and improvements in access to DTF technology for small businesses. As more suppliers enter the market, it is easier for industry players to adopt DTF printing, enhancing their offerings and catering to niche markets.

| Key Point | Description |

|---|---|

| Introduction | DTF transfers represent an innovative and influential method in the fabric printing landscape. |

| What are DTF Transfers? | A technique that prints designs on coated films for high-quality graphics on fabric. |

| Advantages | Quality, durability, versatility, and cost-effectiveness make DTF transfers appealing. |

| Market Growth | Increasing demand for customizable apparel is driving the growth of the DTF market. |

| Recent Developments | More suppliers entering the market, making DTF accessible for businesses and entrepreneurs. |

| Environmental Considerations | DTF inks are often water-based, providing a more sustainable option compared to traditional inks. |

| Challenges | Learning curves in heat pressing and maintaining quality can be challenging for new users. |

Summary

DTF transfers are revolutionizing the fabric printing industry by offering cutting-edge solutions that meet the needs of modern consumers and businesses. This innovative printing technique combines high-quality graphics, exceptional durability, and versatility across various fabric types, making it an ideal choice for countless applications. As the demand for unique and personalized items grows, DTF transfers are rapidly being adopted by businesses eager to enhance their product lines while also appealing to environmentally conscious consumers. The combination of affordability and sustainability within DTF technology not only positions it as a leader in the current market but also ensures its continued relevance in the evolving landscape of fabric printing. Ultimately, embracing DTF transfers means adopting a forward-thinking approach to customization that aligns with the future of responsible manufacturing and design.