When it comes to customizing garments and creating unique DIY projects, understanding **DTF Transfers vs. HTV** is essential. Both of these methods are at the forefront of fabric customization methods, offering distinct advantages for DIY enthusiasts. DTF printing allows for vibrant, full-color designs that can capture intricate details, while HTV is celebrated for its simplicity and variety of vinyl colors. This article explores the heat transfer techniques showcased by these two popular options, helping you make an informed decision for your projects. Whether you’re diving into DIY t-shirt printing or other fabric ventures, knowing the differences between DTF and HTV will enhance your creative experience.

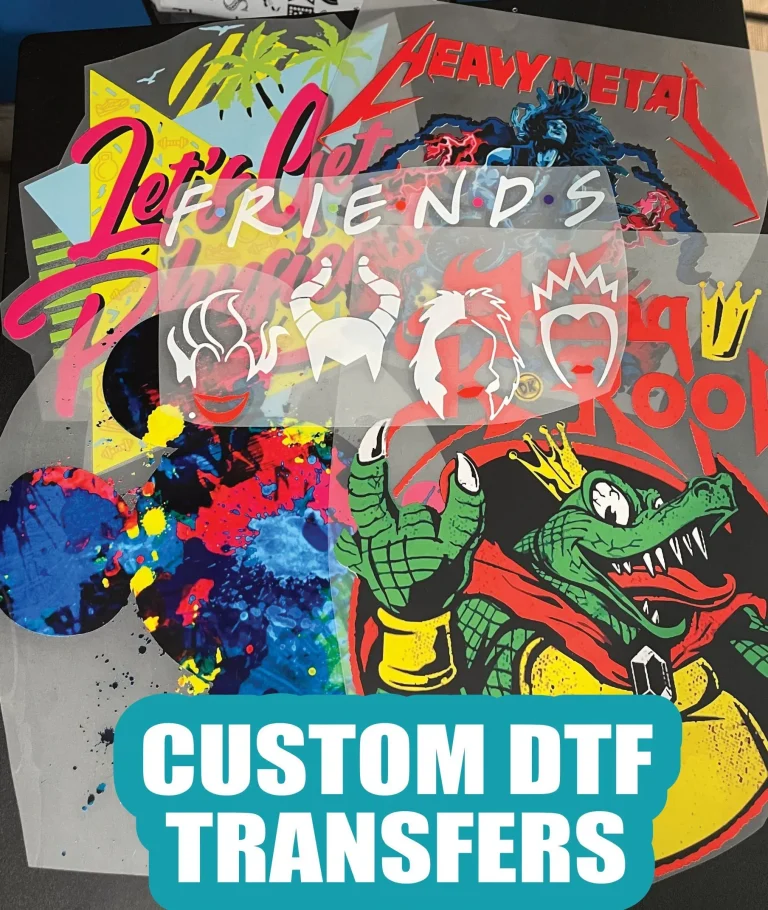

In the world of garment customization, DTF transfers and heat transfer vinyl (HTV) stand out as two prominent techniques. DTF, or Direct-to-Film printing, reveals vibrant designs through direct application onto fabric from a film, making it ideal for intricate and colorful artwork. On the other hand, HTV vinyl comparison highlights a method that entails cutting vinyl sheets and transferring them onto fabric, known for its user-friendliness and wide array of finishes. Whether you’re exploring fabric decoration or embarking on DIY apparel projects, understanding these diverse heat transfer options will empower your creative endeavors.

Understanding DTF Printing Technology

DTF printing technology represents a significant advancement in the realm of fabric customization methods. This innovative process uses a specialized film that captures high-quality ink designs, which are then transferred under heat and pressure to various textiles. By leveraging the capabilities of modern printers, DTF allows for intricate and colorful graphics that are ideally suited for custom apparel, making it a popular choice amongst DIY enthusiasts. Furthermore, the method supports a wide range of materials, from cotton to polyester blends, providing versatility for different project requirements.

Unlike traditional methods that rely on vinyl, DTF’s ability to print directly onto film enables designers to embrace more complex art styles. Elements such as gradients and intricate detailing shine in DTF prints, making them an excellent option for personalized t-shirts, hoodies, and other garments. As the crafting community leans towards more sophisticated and vibrant designs, understanding the nuances of DTF becomes crucial for those aiming to elevate their fabric projects.

Exploring HTV Vinyl Comparison

HTV vinyl has long been a favored choice among crafters thanks to its simplicity and range of colors and textures. This method involves cutting designs from colored vinyl sheets using cutting machines, making it particularly user-friendly for beginners in DIY t-shirt printing. Once cut, the design is heat-pressed onto the fabric, creating a durable bond. However, this process may involve a time-consuming weeding phase, especially for detailed designs.

When comparing HTV to DTF, it becomes evident that while HTV excels in straightforward applications and customization, it may falter with intricate images. The limitations in complexity relative to DTF printing capabilities mean that HTV is better suited for simpler motifs or logos. As the crafting landscape evolves, many creators are evaluating the strengths of HTV against newer technologies, finding their preferred niche based on the nature of their projects.

Durability and Washability of DTF and HTV

Durability and washability are critical factors when determining the best heat transfer technique for fabric projects. DTF transfers are highly regarded for their resilience, often outlasting HTV in terms of washability. Once properly applied, DTF prints maintain their vibrancy and integrity, resisting fading and cracking even after multiple laundry cycles. This characteristic is particularly appealing for those looking to produce high-quality, long-lasting apparel.

On the other hand, while HTV is also known for its durability, it may experience issues if not applied correctly. Peeling or fading can occur if the heat and pressure settings are insufficient during application. Therefore, take care to follow the manufacturer’s guidelines closely to ensure your HTV projects stand the test of time. In essence, your choice between DTF and HTV will hinge on your project requirements and desired durability levels.

Material Compatibility in Customization Methods

Material compatibility is another crucial aspect when considering DTF transfers and HTV for your DIY projects. DTF excels in its ability to bond with a diverse array of fabrics, including cotton, polyester, and blends, making it an incredibly versatile option. This suitability allows users to create vibrant, custom designs on a multitude of garments, catering to various fabric choices that today’s fashion world demands.

Conversely, HTV primarily adheres best to cotton and its blends, though it also has variations designed for synthetic materials. Selecting the right HTV for your fabric is essential, as using the wrong type could compromise the transfer’s quality and longevity. As such, understanding material compatibility plays a significant role in choosing between DTF and HTV for your projects.

Cost Comparison of DTF and HTV Production

When embarking on various DIY fabric projects, the cost associated with DTF transfers and HTV is a definitive consideration for many crafters. DTF printing can require a more considerable initial investment due to the necessary equipment, such as DTF printers and specialized film sheets. However, for businesses or individuals planning to produce high volumes of custom designs, the long-term savings may outweigh the upfront costs.

In comparison, HTV is often the more accessible option, particularly for small business owners and hobbyists already possessing cutting machines like Cricut or Silhouette. The materials required for HTV, such as vinyl sheets, tend to be lower in price and easier to obtain. Thus, while HTV may offer a less costly entry point, potential investors should weigh their budget against the volume and complexity of their planned projects when making a decision.

Future Trends in Fabric Customization

As we move forward, the trends in fabric customization are increasingly leaning towards advanced techniques such as DTF printing. The capacity to produce intricate designs with sharp colors and detail is gaining traction among DIY enthusiasts and small business owners alike. DTF’s fast application and high-quality output enable crafters to meet the growing consumer demand for personalized apparel without sacrificing quality.

Meanwhile, HTV continues to hold a strong position for those who favor simplicity and accessibility in their crafting endeavors. As technology progresses, we may witness an evolution in HTV materials that could expand their capabilities further. Ultimately, the future of fabric customization may see a harmonization of both methods, allowing creators to select the best application based on their project’s specific needs and desired outcomes.

Frequently Asked Questions

What are the main differences between DTF Transfers and HTV?

The primary differences between **DTF Transfers** and **HTV** (Heat Transfer Vinyl) include the printing process and design capabilities. DTF involves printing designs onto a film that is then transferred to the fabric, making it ideal for intricate and colorful designs. On the other hand, HTV requires cutting vinyl designs that are then heat-pressed onto the fabric, which is great for simpler projects.

Is DTF printing better for complex designs compared to HTV?

Yes, **DTF printing** is superior for complex designs. It provides vibrant colors, detailed images, and the ability to create gradients, making it perfect for custom art and photographs. In contrast, **HTV** works best with simpler designs, and while it can layer for complexity, it may not capture fine details as well as DTF.

How do DTF Transfers and HTV compare in terms of durability and washability?

Both **DTF Transfers** and **HTV** are durable, but DTF is known for superior washability. DTF transfers resist fading and cracking through multiple washes when applied correctly. **HTV**, while durable, can sometimes peel or fade, especially if the application isn’t done with the right heat and pressure.

What materials work best with DTF Transfers and HTV?

**DTF Transfers** are versatile and can be applied to a variety of fabrics including cotton, polyester, and blends. In contrast, **HTV** generally adheres best to cotton and its blends, with specific types available for synthetics, though these require careful selection.

Which method, DTF Transfers or HTV, is more cost-effective for DIY t-shirt printing?

The cost-effectiveness of **DTF Transfers** versus **HTV** depends on your production volume. DTF has a higher initial investment due to printing equipment but can lead to cost savings over time for bulk projects. **HTV** is more accessible for beginners, especially if they already own a cutting machine.

Why is DTF gaining popularity compared to HTV in fabric customization?

**DTF printing** is gaining popularity due to its ability to produce high-quality designs quickly and efficiently. Many small businesses and DIY enthusiasts are drawn to DTF for its versatility and capability to handle complex designs, while **HTV** remains favored for simpler crafting endeavors.

| Factor | DTF Transfers | HTV |

|---|---|---|

| Process and Ease of Use | Requires specialized printing, but is user-friendly with equipment. | Involves cutting vinyl, time-consuming but simple for beginners. |

| Design Complexity | Excels in intricate designs with great detailing and color resolution. | Best for simpler designs; complex layering may lose definition. |

| Durability and Washability | Superior durability, resistant to fading and cracking with care. | Durable but may peel or fade if not applied properly. |

| Material Compatibility | Works with various materials (cotton, polyester, blends). | Best suitable for cotton; requires special types for synthetics. |

| Cost and Equipment | Higher initial investment for printing equipment; cost-efficient for high volume. | More accessible, requiring mostly a cutting machine. |

Summary

DTF Transfers vs. HTV are two of the most prominent methods for customizing garments, each with its own unique strengths and weaknesses. DTF Transfers leverage a modern printing technique that allows for vibrant, intricate designs on a variety of fabrics, making them an excellent choice for detailed works. Conversely, HTV, with its straightforward application of colored vinyl, appeals to those seeking convenience and simplicity. Understanding the differences in processes, design capabilities, durability, material compatibility, and costs between these two methods will empower creators to select the best option for their specific projects. Ultimately, whether you opt for DTF or HTV, both methods can elevate your DIY endeavors and unleash your creativity.