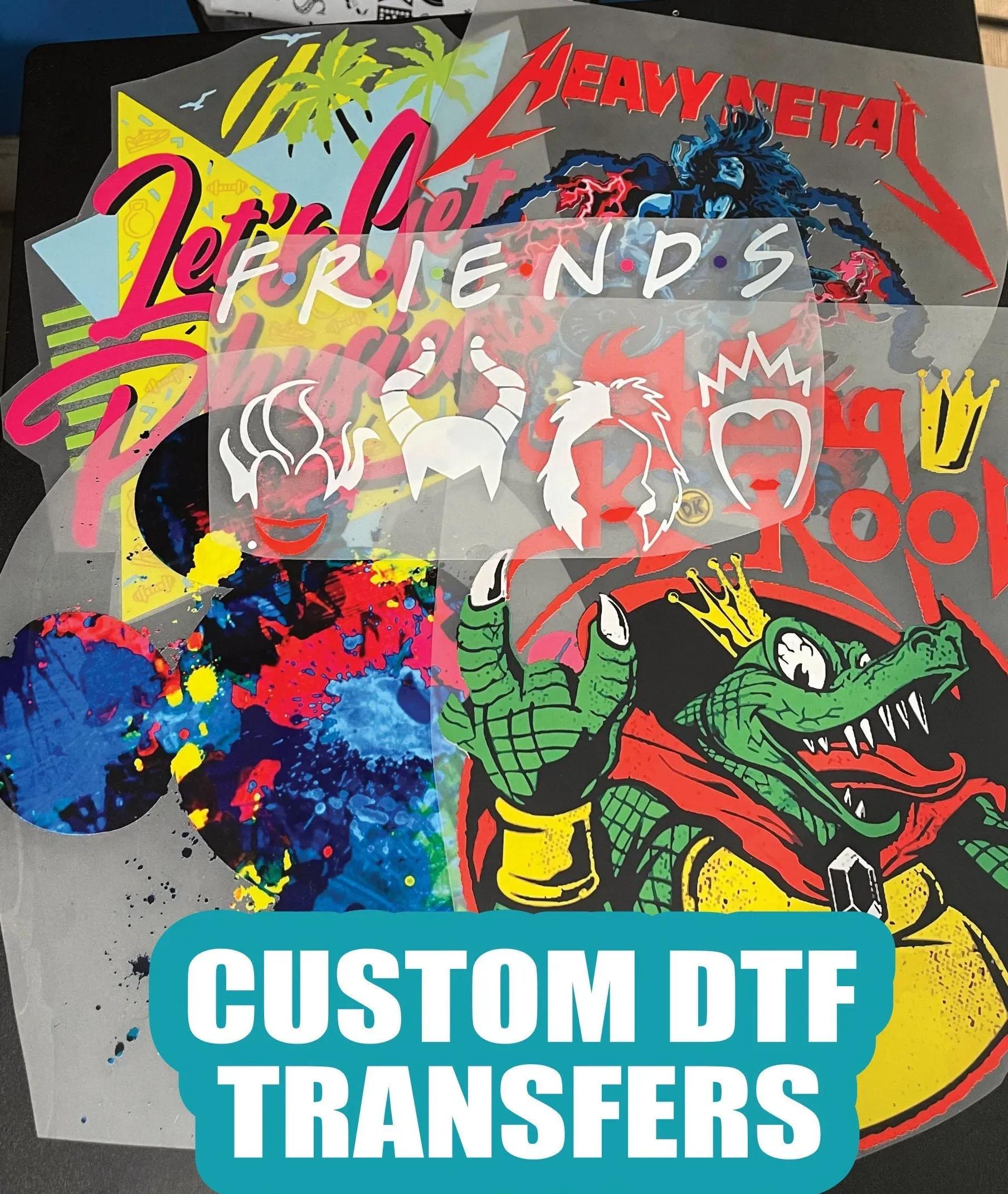

DTF transfers, or Direct to Film transfers, are revolutionizing the way fashion designers approach garment decoration and customization. This innovative printing technique allows for high-quality, full-color images to be applied directly onto various fabrics, vastly expanding creative possibilities in custom apparel production. As designers seek to differentiate themselves in a crowded marketplace, DTF transfers offer a versatile, cost-effective, and efficient solution that minimizes production time while maximizing visual impact. The ability to reproduce intricate designs seamlessly sets DTF printing apart from traditional methods, marking it as one of the most exciting advancements in fashion printing techniques. In this blog post, we will explore the benefits of DTF transfers, their role in textile innovation, and how they are shaping the future of fashion design technology.

Direct to Film (DTF) printing, often referred to as film transfer printing or DTF heat transfer, is gaining popularity as a go-to method for fashion designers looking to enhance their creative offerings. This modern approach enables the application of vivid and detailed graphics onto a variety of substrates, making it a preferred choice for those who specialize in custom apparel. With its ability to adapt to different fabric types and its swift production turnaround, DTF has become synonymous with innovation in textile applications. As fashion professionals explore new technologies, the impact of DTF transfers in the realm of fashion design is proving to be significant, ushering in a new era of bespoke fashion solutions.

Understanding the Basics of Direct to Film Transfers

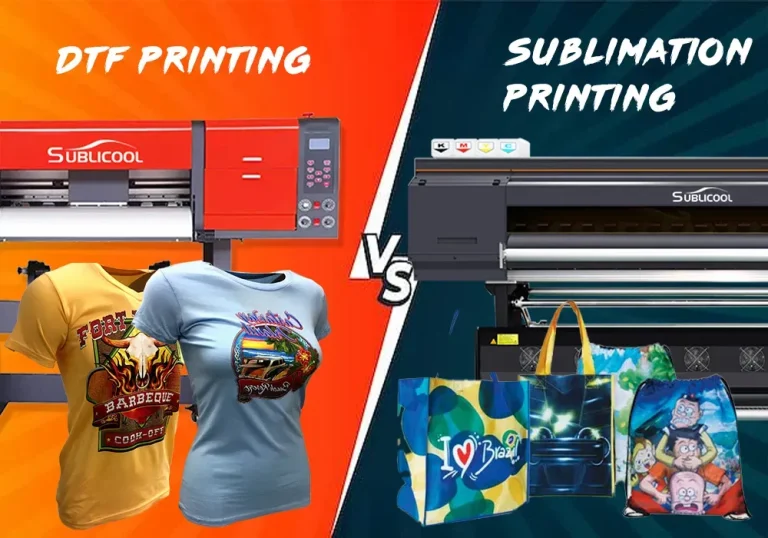

Direct to Film (DTF) transfers are revolutionizing the way fashion designers approach fabric printing. This technology involves printing images onto a special film which is then transferred to a fabric of choice. Unlike traditional methods such as screen printing, DTF allows for a wider color spectrum and the ability to print intricate designs with exceptional detail. This innovation is particularly beneficial in the fast-paced world of fashion where designers need to bring their visions to life quickly and efficiently.

Furthermore, DTF technology provides the flexibility to work with various materials, which is a significant advantage for designers looking to diversify their product offerings. Whether it’s cotton, polyester, or blends, DTF transfers have proven effective on multiple fabric types. This adaptability allows designers to experiment with unique styles and materials, thus enhancing their creative potential and ultimately contributing to the evolution of fashion design.

Benefits of DTF Transfers in Fashion Design

One of the main advantages of DTF transfers is the remarkable clarity and vibrancy of the prints. Unlike some traditional printing techniques that may leave designs looking washed out, DTF technology excels in reproducing vivid colors and fine details. This is paramount for fashion designers who seek to showcase their artwork in its truest form. Designers can create garments that not only stand out but also resonate with their intended audience, drawing them deeper into the fashion narrative.

Additionally, DTF transfers prove to be a cost-effective solution for both large brands and independent designers. With lower setup costs compared to screen printing, DTF enables designers to produce small batches or even unique custom pieces without overwhelming financial investment. This characteristic is especially advantageous in an industry where taking risks on new designs can be daunting. By adopting DTF, designers can meet client demands for bespoke apparel while keeping costs manageable.

The Impact of DTF Transfers on Custom Apparel Production

The rise of DTF transfers directly contributes to the booming trend of custom apparel. As consumers increasingly seek personalized clothing, fashion designers are utilizing DTF technology to cater to this demand. The ability to quickly produce high-quality, individualized pieces allows brands to maintain a competitive edge in a crowded marketplace. Designers can now offer unique items that tell a story, create a personal connection with customers, and build brand loyalty.

Moreover, with customers craving individuality, DTF transfers provide a means for designers to push the boundaries of fashion. They can explore bold patterns and intricate designs without the worry of compromising quality. DTF’s versatility ensures that whatever the desired look—be it for streetwear, high fashion, or athleisure—designers have the tools to manifest their creative ideas effectively.

Recent Trends in DTF Technology

As of 2023, the adoption of DTF printing technology has gained significant momentum among fashion designers. A growing number of small to medium-sized businesses are integrating this printing method into their production processes. Reports suggest that designers are increasingly leveraging DTF to stand out in a saturated market by creating eye-catching, custom apparel that resonates with contemporary fashion trends. This shift highlights the technology’s adaptability, allowing designers to maintain relevance in an ever-evolving fashion landscape.

Technological advancements have also played a crucial role in the rise of DTF transfers. New innovations have enhanced the quality and durability of prints, ensuring that the final product withstands wear and washes effectively. For designers, this means greater assurance about the longevity of their creations—an important consideration for consumers looking for sustainable options. With technology improving rapidly, the future looks promising for DTF transfers and their role in textile innovation.

Designing for the Future: How DTF is Shaping Fashion Technology

DTF technology is at the forefront of transforming fashion design, providing a framework for integrating advanced printing techniques into standard practices. Designers can leverage the ability to create complex graphics which were previously difficult to achieve, pushing the limits of what is possible in garment decoration. This evolution not only enhances the aesthetic appeal of fashion items but also strengthens the narrative behind each piece, making the collections more compelling and engaging.

Moreover, the market is responding positively to these innovations, with projections indicating robust growth for DTF technology in the coming years. As designers embrace fashion design technology alongside their creative processes, we can expect to see a variety of fresh approaches to styling, branding, and market engagement strategies. As the fashion industry progresses, DTF will undoubtedly remain a crucial component of designer toolkit, shaping the future of custom apparel.

Embracing DTF Transfers: A New Era for Fashion Designers

As fashion trends continue to evolve, embracing DTF transfers may very well be the key to unlocking new creative possibilities for designers. This technique not only fosters artistic freedom—allowing for diverse artistic expression—but also encourages innovation within custom apparel production. With the ability to produce vibrant, detailed designs at a lower cost, designers can experiment without fear, driving deeper connections with their audience and offering them something truly unique.

Furthermore, as sustainability becomes a cornerstone of modern fashion, DTF technology aligns well with these values. The ability to print on demand and create custom pieces helps reduce waste, making it an appealing choice for environmentally conscious designers. As we move forward, integrating DTF transfers into regular practice is likely to redefine the landscape of fashion design, reinforcing the notion that innovation and tradition can go hand in hand.

Frequently Asked Questions

What are DTF transfers and how do they work in fashion design?

Direct to Film (DTF) transfers are an innovative printing technology that allows fashion designers to create high-quality, full-color images on fabric. The process involves printing designs onto a special film, which can then be transferred onto garments such as t-shirts and hoodies. This method is highly favored for its precision and ability to reproduce intricate designs, making it ideal for those in the custom apparel market.

What are the benefits of using DTF transfers over traditional printing techniques?

DTF transfers offer several advantages compared to traditional methods like screen printing and heat transfer vinyl. They are more versatile, can be applied to various fabric types, and require lower setup costs, making them cost-effective, especially for small batch productions or custom designs. Additionally, DTF technology provides detailed imagery with intricate designs and offers a quicker turnaround time, which is essential in the fast-paced fashion industry.

Which fabrics can be used with Direct to Film transfers?

DTF transfers are highly versatile and can be used on a wide range of fabrics, including cotton, polyester, and fabric blends. This flexibility makes DTF a popular choice for fashion designers looking to create custom apparel across different fashion items, from casual tees to more elaborate garments.

How has DTF technology evolved in recent years?

Recent advancements in Direct to Film transfer technology have significantly improved print quality and durability. Innovations have led to more vibrant and resilient prints that withstand wear and washing, which is critical for fashion designs focused on longevity and user satisfaction. Designers can now leverage these improvements to enhance their product offerings and stay competitive in the textile innovation landscape.

Is DTF transfer printing suitable for small fashion businesses?

Yes, DTF transfer printing is particularly well-suited for small to medium-sized fashion businesses due to its cost-effectiveness and low setup costs. This technology allows these designers to produce custom apparel without incurring significant financial risks, encouraging creativity and personal branding in their designs.

What trends are emerging in the use of DTF transfers within fashion design?

In 2023, there is a notable increase in the adoption of DTF transfers among fashion designers, driven by a growing demand for custom apparel. Trends indicate that designers are capitalizing on the potential of DTF technology to differentiate themselves in a saturated market, responding more effectively to client needs. This trend in fashion design technology is contributing to the overall growth of the DTF market, highlighting its significance in modern textile innovation.

| Key Point | Details |

|---|---|

| What is DTF Transfer? | A printing method that transfers high-quality, full-color images onto various fabrics using a special film. |

| Versatility | Can be applied to different fabrics (cotton, polyester, etc.) suitable for various fashion projects. |

| Cost-Effectiveness | Lower setup costs compared to screen printing, beneficial for small runs and custom designs. |

| Detailed Imagery | Capable of reproducing complex designs with intricate details and gradients. |

| Quick Turnaround | Faster production times than many traditional methods, facilitating quick market responses. |

| Recent Trends | Increased adoption among small to medium businesses and technological improvements enhancing quality. |

| Market Growth | Projected rapid growth in DTF market driven by rising demand for custom apparel. |

Summary

DTF transfers are reshaping the fashion industry by providing designers with a unique and efficient means of producing high-quality garments. This advanced method not only enhances creativity through its versatility and ability to deliver intricate designs but also offers economic advantages, particularly for emerging designers looking to make their mark. The growing popularity and advancements in DTF technology highlight its pivotal role in modern fashion, making it essential for any designer looking to stay competitive. By embracing DTF transfers, designers can unlock new creative possibilities and ensure their work stands out in a dynamic marketplace.