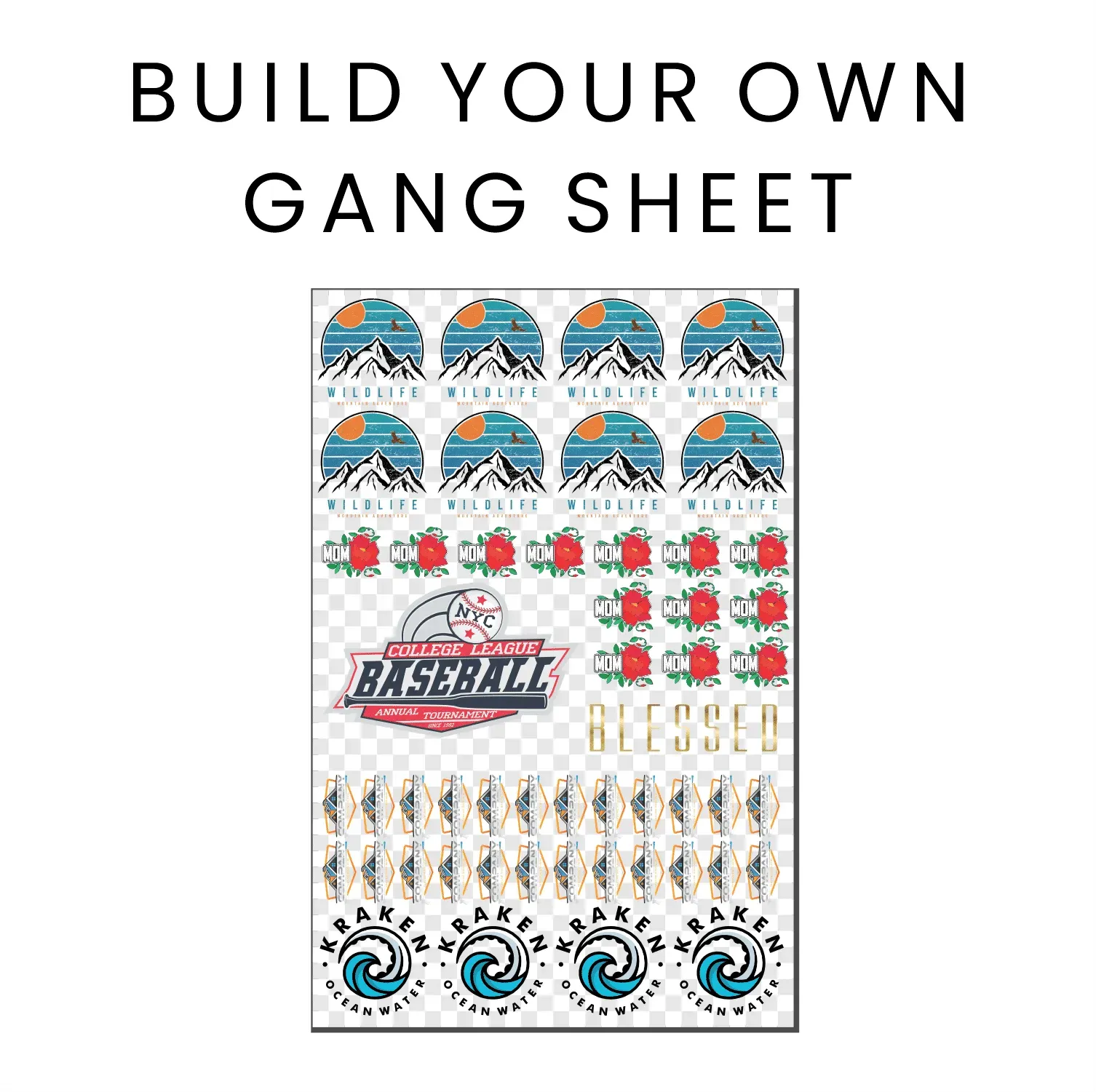

In the ever-evolving landscape of custom textile printing, the DTF Gangsheet Builder stands out as a game-changer for artists and print operators alike. This innovative tool empowers users to effectively streamline their designs into gang sheets, making the direct-to-film (DTF) printing process smoother and more efficient. By harnessing the capabilities of the DTF Gangsheet Builder, creators can produce vibrant prints that showcase their unique styles while optimizing material usage. In this comprehensive tutorial, we will guide you through each step of creating stunning designs with the DTF Gangsheet Builder, ensuring you achieve maximum output with minimal waste. Whether you are a seasoned professional or a beginner, understanding this technology is key to elevating your custom textile printing game.

When it comes to custom apparel creation, utilizing a gang sheet builder can significantly simplify your workflow. The Direct-to-Film (DTF) method, popular among textile designers, allows for direct application of graphics onto special films, enabling a seamless transition of detailed images onto fabric. By exploring the DTF Gangsheet Builder, you’ll discover how to arrange multiple designs on a single sheet, enhancing efficiency and reducing production costs. With an emphasis on direct-to-film printing techniques, this step-by-step guide will provide you with valuable insights and best practices for maximizing your gang sheets. Dive into the world of custom printing and unlock the potential of your designs with the right approach to textile technology.

Introduction to Direct-to-Film (DTF) Printing

Direct-to-Film (DTF) printing is an innovative technique that has transformed the landscape of custom textile printing. Unlike traditional printing methods, DTF allows for vibrant and detailed designs to be directly printed onto a special film, which is later transferred onto fabric. This process involves using high-quality DTF inks that ensure flexibility and durability, allowing the printed designs to withstand multiple washes without fading. As this method gains traction among apparel manufacturers and designers, understanding its intricacies becomes imperative for those looking to create high-quality prints.

The DTF process entails several crucial steps: printing the design onto a transfer film, applying heat-sensitive adhesive powder, and finally using heat transfer to bond the design with the fabric. This combination of steps not only streamlines the printing process but also reduces waste and maximizes material efficiency. For businesses that rely on bulk orders, DTF printing presents a viable solution for delivering impressive, long-lasting results while maintaining cost-effectiveness.

Understanding Gang Sheets in DTF Printing

A gang sheet is a critical concept in the DTF printing workflow, specifically designed to maximize the use of materials and reduce costs associated with printing multiple designs. By arranging several designs on a single sheet, gang sheets enable printers to optimize their resources, particularly when catering to bulk orders or diverse design requests. This technique not only saves time during the printing process but also minimizes waste, a vital consideration for environmentally conscious businesses.

Implementing gang sheets requires attention to detail, especially during the design phase. Proper spacing and alignment of individual designs are essential to ensure flawless transferring and cutting. By adopting this method, designers can significantly enhance their productivity while still delivering high-quality prints that meet client expectations. Therefore, mastering the art of creating and utilizing gang sheets is crucial for anyone looking to succeed in the DTF printing industry.

How to Use the DTF Gangsheet Builder Effectively

The DTF Gangsheet Builder is an essential tool for anyone involved in custom textile printing. It simplifies the arrangement and organization of multiple designs on one film sheet, which translates to increased efficiency and reduced printing costs. To effectively use this builder, designers must first select an appropriate design software that can handle vector files, ensuring all elements are visually appealing and accurately represented on the final print.

Once in the DTF Gangsheet Builder, users can create individual designs or import pre-made graphics. It’s essential to maintain high-resolution images and use the CMYK color model to ensure vibrant output. The meticulous arrangement of designs, optimal spacing, and careful setup of canvas dimensions are crucial for achieving top-notch results. By following these best practices while utilizing the Gangsheet Builder, designers can ensure they produce high-quality products that stand out in the competitive custom printing market.

Step-by-Step Guide: Creating Prints with DTF Gangsheet Builder

Creating prints using the DTF Gangsheet Builder involves a systematic approach that begins with selecting the right design software. Programs like Adobe Illustrator or CorelDRAW are popular choices among professionals due to their robust features tailored for graphic design. Understanding how to navigate these platforms is vital for arranging designs effectively and ultimately achieving superior print quality.

After the design elements are in place, setting up the canvas size to match the dimensions of the gang sheet is critical. Adequate spacing between designs must be maintained to prevent misalignment during the printing process. Once everything is arranged beautifully, conducting a test print with regular paper can help identify layout issues before committing to actual transfers. By following these steps carefully, you can create stunning prints that reflect your unique style and meet your clients’ needs.

Best Practices for DTF Printing and Gang Sheets

To optimize the use of the DTF Gangsheet Builder and achieve the best results with DTF printing, incorporating quality control measures throughout the process is essential. Regular quality checks not only maintain consistent standards but also help identify potential issues before they escalate. This proactive approach ensures high satisfaction rates among clients, as they receive products that reflect attention to detail and craftsmanship.

Engaging with online communities is another best practice that can significantly enhance your DTF printing skills. Forums, social media groups, and discussion boards focused on DTF printing provide invaluable insights, tips, and troubleshooting advice from experienced users. Additionally, staying updated with the latest advancements and trends in DTF technology can further refine your processes, allowing for continuous improvement in output quality.

The Future of DTF Printing and Gang Sheets

As DTF printing technology evolves, the potential applications for gang sheets are expanding. Innovations in textiles and printing methods pave the way for more flexible and creative designs that can cater to the ever-changing fashion and apparel landscape. Businesses that embrace these advancements stand to benefit from increased efficiency and superior product offerings, driving customer satisfaction and loyalty.

Moreover, the growing demand for personalized and custom designs underscores the importance of mastering techniques like the DTF Gangsheet Builder. As clients seek unique creations, mastering this process will place you at the forefront of the custom printing industry, allowing you to meet diverse needs while optimizing materials and costs. By keeping an eye on industry trends and continuously honing your skills, you can ensure your work remains relevant and competitive in a rapidly changing market.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a specialized tool used in the Direct-to-Film (DTF) printing process that allows designers to create multiple designs on a single transfer film, known as a gang sheet. This method maximizes material efficiency and reduces printing costs by allowing several graphics to be printed simultaneously, ensuring cost-effective custom textile printing.

What are the advantages of using DTF printing with a gang sheet?

Using DTF printing with a gang sheet offers numerous advantages including reduced material waste, cost savings, and improved efficiency. By consolidating multiple designs into one print run, you can streamline your production process and achieve vibrant, durable prints that adhere well to various fabric types.

How do I prepare my designs for the DTF Gangsheet Builder?

To prepare your designs for the DTF Gangsheet Builder, start with high-resolution images in vector format. Utilize design software such as Adobe Illustrator to create your designs, ensuring text is converted to outlines or rasterized. Set up your canvas to match your gang sheet dimensions for optimal layout before exporting the final file for printing.

Can I use any fabric with DTF printing and the Gangsheet Builder?

Yes, DTF printing is compatible with various fabrics including cotton, polyester, and blends. The DTF Gangsheet Builder allows for versatility in custom textile printing, enabling you to create high-quality prints on a multitude of fabric types, suitable for various apparel and merchandise.

What are the steps involved in using the DTF Gangsheet Builder for printing?

The steps to using the DTF Gangsheet Builder include: 1) choosing the right design software; 2) creating your designs; 3) setting up your canvas; 4) arranging your designs; 5) testing and adjusting; 6) saving and exporting your file; 7) loading the design into the DTF printer; 8) printing and transferring your designs to fabric; and 9) conducting a final inspection of the printed product.

Where can I find additional resources or tutorials on DTF printing and gang sheets?

You can find additional resources and tutorials on DTF printing and gang sheets on websites like Printful, Printavo, and Avery. Additionally, forums like Reddit provide community discussions and shared experiences that can enhance your understanding and skills in DTF printing techniques.

| Step | Description |

|---|---|

| 1 | Choose design software (e.g., Adobe Illustrator, CorelDRAW) that supports vector files. |

| 2 | Create/import your designs, ensuring text is converted to outlines for compatibility. |

| 3 | Set a canvas size according to gang sheet dimensions, ensuring proper spacing for alignment. |

| 4 | Arrange designs strategically for visual appeal and cost-effectiveness. |

| 5 | Print a test sheet on regular paper to check layout and alignment. |

| 6 | Save and export your design in a compatible format for the DTF printer (e.g., PNG, PDF). |

| 7 | Load film and adhesive into the printer, adjusting settings as necessary. |

| 8 | Initiate the printing process and monitor for color alignment and quality. |

| 9 | Sprinkle adhesive powder on the printed film and cure using a heat press. |

| 10 | Inspect the final product for quality and defects to ensure product standards. |

Summary

The DTF Gangsheet Builder is a revolutionary tool in the custom printing industry that empowers designers to create high-quality prints efficiently. This detailed tutorial underscores essential procedures, from selecting suitable design software to conducting final product inspections. By leveraging gang sheets, print operators not only optimize their material usage but also realize significant cost savings. The DTF printing process provides unmatched vibrancy and detail, making it an ideal choice for apparel manufacturers. By embracing the DTF Gangsheet Builder, you can explore immense creative possibilities and streamline your printing workflow.