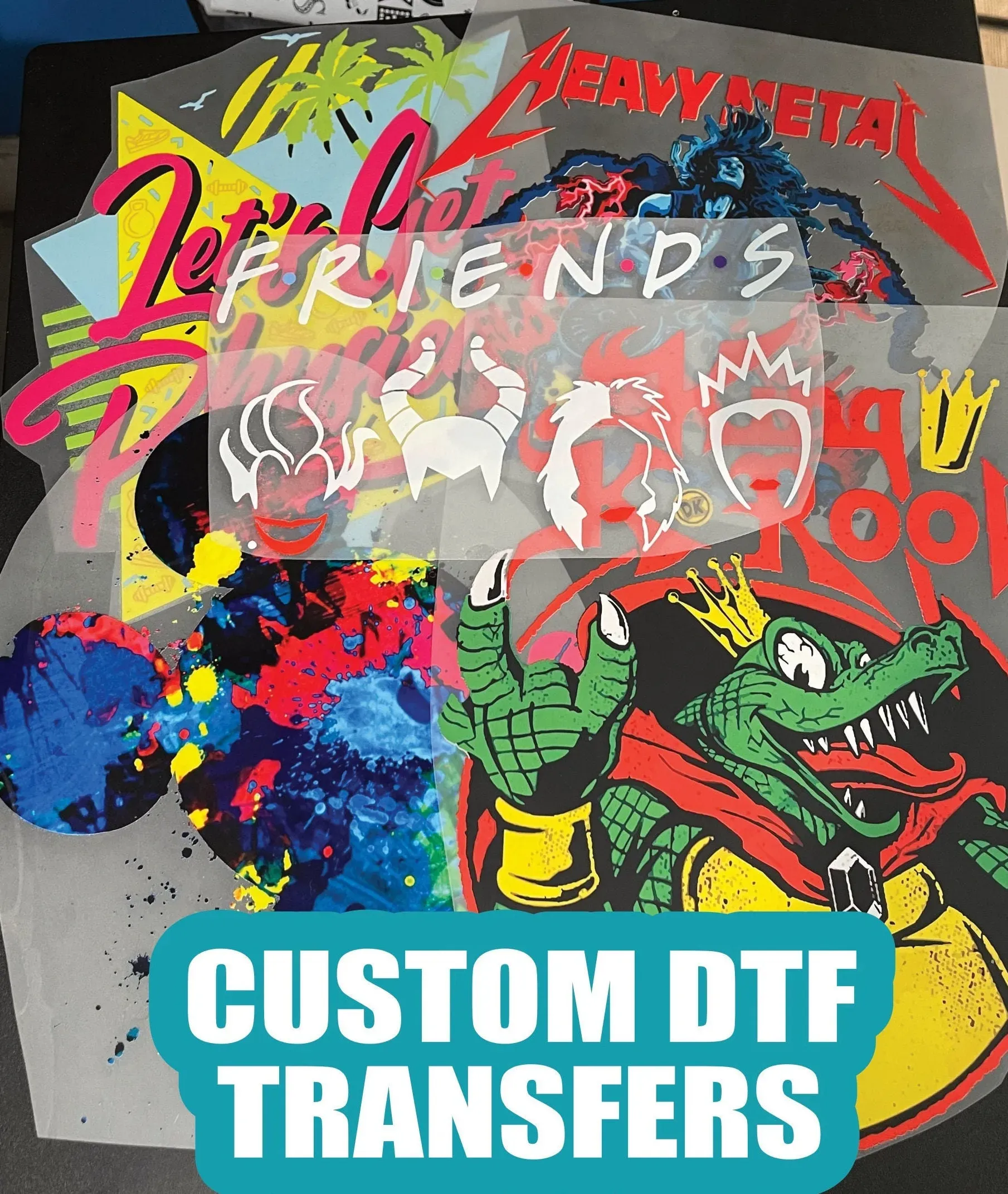

DTF Transfers, or Direct-to-Film printing, is revolutionizing the textile printing industry with its cost-effective printing solutions and remarkable versatility. Unlike traditional printing methods, such as screen printing or direct-to-garment (DTG), DTF offers unique advantages by combining speed and quality, making it an appealing choice for custom apparel creators. In this blog post, we will delve into the nuances of DTF printing, exploring its growing prominence in comparison to established techniques. We will examine the benefits of DTF Transfers and discuss critical factors like durability, production speed, and design intricacy. Whether you’re a seasoned professional or a newcomer to textile printing, understanding these distinctions will empower you to make informed decisions that align with your creative vision and budget.

In the realm of custom apparel and fabric decoration, Direct-to-Film printing brings a fresh perspective to traditional fabric printing techniques. This modern approach offers a dynamic alternative to conventional options like screen printing and heat transfers, emphasizing efficiency and artistry. By embracing this innovative textile printing method, creators can explore a variety of applications while enjoying faster turnaround times and superior print quality. As we navigate the world of printing solutions, it’s essential to evaluate the strengths of DTF methods against time-honored practices. This examination will reveal how current advancements are reshaping the landscape of fabric decoration.

Understanding DTF Transfers and Traditional Printing

The world of textile printing has seen remarkable transformations, particularly with the introduction of DTF (Direct-to-Film) transfers. Unlike traditional printing methods such as screen printing or DTG, DTF utilizes a unique process where designs are printed onto a special film which is then transferred to fabric using heat and pressure. This allows for vibrant colors and sharp detail, making it an appealing choice for brands looking for high-quality prints. In contrast, traditional methods have established reputations, with screen printing known for durability and cost-efficiency with bulk orders. Yet, they often struggle with intricate designs and require more setup, making them less adaptable for smaller quantities or individual projects.

While choosing between DTF and traditional printing methods, it’s crucial to consider the technology and process behind each. DTF printing has quickly gained attention for its capacity to produce intricate designs, while traditional screen printing often involves multiple layers and complex setups. This complexity can translate into longer production times. Additionally, traditional methods might not accommodate the same versatility as DTF, which is particularly suited for diverse fabric types and allows for smaller runs without significant cost implications.

Cost Efficiency of DTF Transfers Compared to Traditional Methods

In today’s competitive market, understanding cost-efficient printing solutions is essential for both established brands and small businesses. DTF transfers offer a significant advantage in this aspect as they require lower setup costs than traditional screen printing. With DTF, there’s no need for expensive screens, making it a more accessible option for short runs or one-off designs. This lower barrier to entry empowers smaller businesses and creators to experiment with custom designs without the heavy financial burden.

On the other hand, traditional methods, particularly screen printing, become cost-effective primarily in larger quantities. The initial setup costs can be justified when producing extensive runs, enabling manufacturers to lower the unit price significantly. However, for low-quantity needs, DTF printing is undoubtedly a more economical choice, allowing for flexibility in order size without sacrificing quality, thus appealing to a broader range of customers.

Comparing Durability: DTF Printing vs. Traditional Techniques

Durability is a key consideration when selecting a printing method, especially for apparel that undergoes regular washing and wear. DTF transfers are known for their robust finish, able to withstand multiple washes without significant fading or cracking, closely matching the durability offered by traditional screen printing methods. This resistance is crucial for creating long-lasting products, instilling confidence in consumers who prioritize quality.

Conversely, traditional heat transfer methods may face challenges, often leading to issues such as peeling or cracking over time. While screen printing excels in durability, it still requires proper technique and material choices to achieve long-lasting results. Thus, when durability is essential, DTF printing provides a reliable solution that simultaneously meets aesthetic demands and functional needs.

Production Speed: How DTF Transfers Outpace Traditional Methods

When time is of the essence, the speed of production becomes a pivotal factor in choosing a printing method. DTF printing typically offers a faster turnaround than traditional methods like screen printing. This is largely due to reduced setup times and fewer overall steps in the DTF process, allowing creators to fulfill orders more rapidly. For businesses dealing with urgent demand or quick fashion trends, DTF proves to be an essential tool in maintaining competitiveness in the market.

In contrast, screen printing often requires meticulous setup for each design and color separation, leading to longer waiting periods for completed orders. While it may be suitable for batch operations, those needing prompt delivery might find DTF transfers to be a more efficient option, highlighting the potential for increased customer satisfaction through quicker order fulfillment.

Ease of Use in DTF vs. Traditional Printing Methods

For newcomers to the world of printing, the learning curve associated with various methods can be daunting. DTF printing stands out for its accessibility; the process involves fewer complex steps than traditional screen printing. As a result, small businesses or hobbyists can quickly ramp up production without the need for extensive training or technical expertise. This ease of use allows creative minds to focus more on design rather than getting bogged down in technicalities.

In contrast, traditional methods may necessitate a more robust understanding of the machinery and processes involved. Screen printing, for instance, can be labor-intensive, often requiring significant mechanical and design knowledge to perfect the output. Consequently, those with limited experience might find DTF printing a more inviting entry point into the world of custom apparel printing.

Environmental Impact of DTF versus Traditional Printing Techniques

As sustainability becomes increasingly pivotal, the environmental impact of printing methods cannot be overlooked. DTF printing has positioned itself as a more eco-friendly option, utilizing advanced technology and inks that minimize waste and decrease harmful chemical usage. Sustainable practices in DTF printing can attract consumers who prioritize environmentally responsible choices, aligning with current market trends.

On the flip side, traditional screen printing has historically involved a range of chemicals and processes that may not be as favorable to the environment. However, many modern printers are shifting toward eco-friendly alternatives and practices to reduce their carbon footprint. By comparing these methods, it becomes evident that while traditional techniques can be improved upon, DTF printing offers inherently less environmental impact, appealing to eco-conscious buyers.

Frequently Asked Questions

What are DTF Transfers and how do they compare to traditional printing methods?

DTF Transfers, or Direct-to-Film transfers, utilize specialized ink and films to create vibrant prints on textiles. Unlike traditional printing methods such as screen printing, DTF printing excels in detail and color reproduction, making it ideal for intricate designs.

What advantages does DTF printing offer over screen printing?

DTF printing advantages include faster setup times and lower costs, especially for small batch productions. Unlike screen printing, which may require extensive setup and color separations, DTF transfers allow for quicker turnarounds and easier design adjustments.

How do DTF Transfers compare with DTG printing techniques?

While DTG (Direct-to-Garment) printing allows for high detail, DTF Transfers often provide better wash durability and are more cost-effective for small runs. DTF also adheres well to various fabric types, making it a versatile choice in comparison to DTG.

Are DTF Transfers a cost-effective printing solution for small businesses?

Yes, DTF Transfers are a cost-effective printing solution, particularly for small businesses or individuals seeking to produce lower quantities. The reduced setup costs and ease of printing make DTF an attractive option compared to traditional methods like screen printing.

What should I consider in terms of durability when choosing between DTF Transfers and traditional printing methods?

DTF Transfers maintain their color and integrity over time, comparable to traditional screen prints when applied correctly. However, heat transfers, a traditional method, may not offer the same longevity, potentially cracking or peeling after multiple washes.

Is DTF printing an environmentally friendly alternative to traditional printing techniques?

DTF printing has made strides towards sustainability by using eco-friendly inks and generating less waste. In contrast, traditional printing methods can involve harmful chemicals unless sustainable practices are adopted, making DTF a greener option overall.

| Aspect | DTF Transfers | Traditional Methods |

|---|---|---|

| Quality and Detail | Excellent color reproduction and intricate details without compromising fabric softness. The ink bonds securely, ensuring longevity. | Durable with rich colors in screen printing, but struggles with fine details and incurs high setup costs for small batches. |

| Cost-Effectiveness | Cost-effective for small to medium runs; minimal setup allows experimentation with one-off designs. | More economical for bulk orders; high setup costs can be offset with large production runs. |

| Ease of Use | Fewer steps involved; more accessible for beginners. | Requires more skill; labor-intensive and time-consuming setup process. |

| Production Speed | Generally faster setup and printing times, allowing quicker order turnarounds. | Slower production due to multiple setup processes, especially with color separations. |

| Durability and Longevity | Maintains colors and integrity over time, comparable to traditional methods when properly executed. | High durability, especially in screen printing, but heat transfers tend to peel or crack. |

| Environmental Considerations | Utilizes eco-friendly inks and reduces waste, aligning with sustainable practices. | Often involves harmful chemicals unless eco-friendly options are selected. |

Summary

DTF transfers present a modern and effective solution in the realm of textile printing, particularly when compared to traditional methods. As businesses and creators seek high-quality, cost-effective options, DTF printing stands out for its vibrant color reproduction, ease of use, and fast production capabilities. By carefully weighing the merits of DTF transfers against traditional printing techniques, individuals can make informed decisions that best align with their project needs and sustainability values.