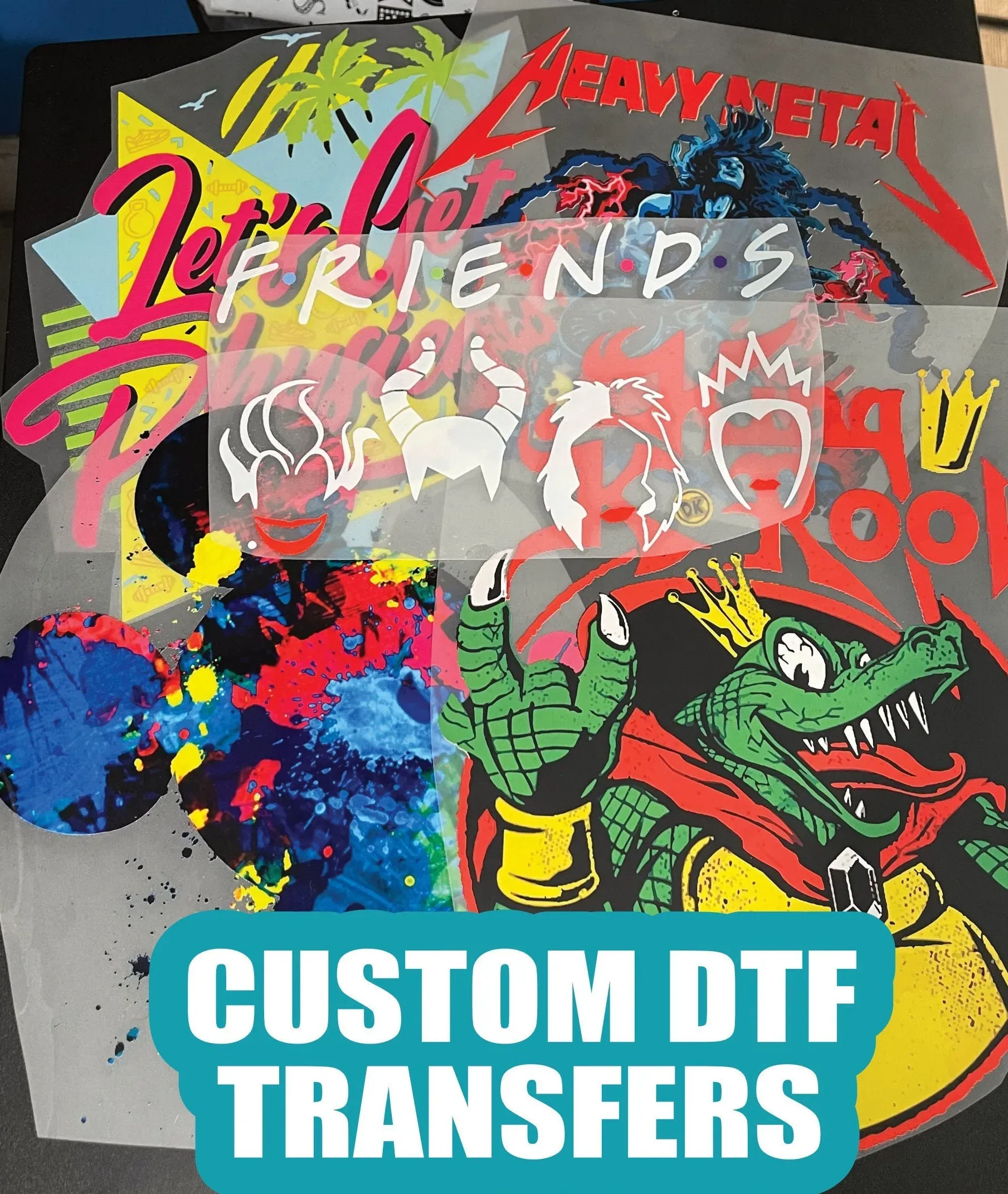

DTF transfers, or Direct to Film transfers, have rapidly gained traction as a preferred method for custom apparel printing in recent years. This revolutionary approach leverages DTF printing technology to produce vibrant, intricate designs that easily transfer onto various materials. The DTF transfer process is not only efficient but also cost-effective, making it an attractive option for aspiring designers and small businesses alike. With the right DTF printing equipment at your disposal, entering this creative realm is more accessible than ever. In this guide, we will explore how to start DTF printing, ensuring you have all the necessary information to embark on your newfound printing adventure.

The world of custom prints has been transformed with the introduction of various transfer methods, among which Direct to Film (DTF) technology stands out. Often described as a cutting-edge solution for printing on textiles, this technique combines high-quality color application with ease of use. By capitalizing on the DTF printing materials and the transfer process, artisans can produce detailed graphics on shirts, hats, and more. Crafting apparel has never been simpler or more efficient with the right DTF printer and supplies. Join us as we delve into the essentials of getting started with this innovative printing method.

Understanding the DTF Transfer Process

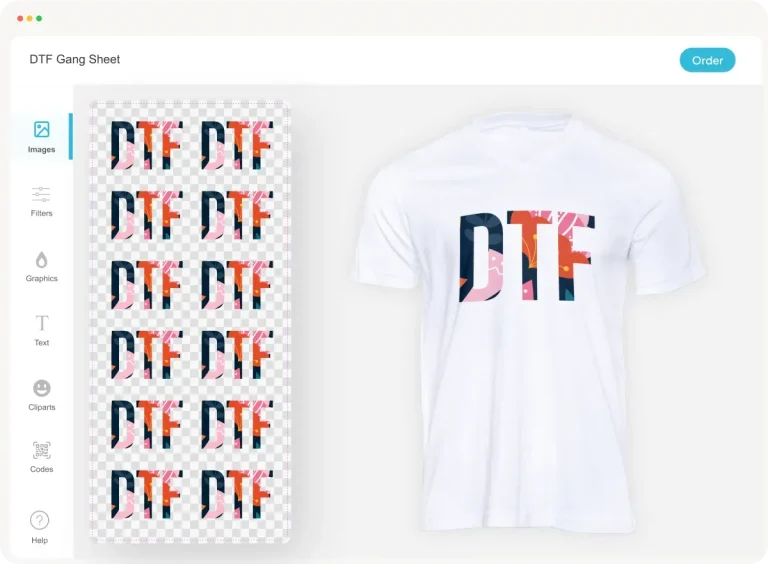

The DTF transfer process is a multi-step technique that combines creativity with technical knowledge. Initially, one needs to create a digital design using graphic design software that is compatible with DTF printing specifications. Once the design is ready, it is printed onto a specialized DTF film using a DTF printer equipped with high-quality DTF inks. The ability to print intricate designs in vivid colors makes DTF a favored option among graphic artists and apparel businesses alike.

Post-printing, the application of DTF powder adhesive is crucial as it solidifies the transfer’s adherence to the fabric. The film is then cured using heat from a heat press, following precise temperature and timing guidelines provided by the manufacturer. Finally, the printed film is placed on the garment and pressed down to transfer the design. Ensuring each of these steps is performed accurately is vital to achieving a durable and appealing printed fabric.

Choosing the Best DTF Printer for Your Needs

When it comes to starting your DTF printing journey, selecting the right printer is critical. The market offers various options, and the best DTF printer for you will largely depend on your specific needs, including budget, print volume, and design complexity. Brands such as Prestige have established a reputation for quality, providing reliable printers that cater to beginners and experienced users alike. Evaluating printer specifications, user reviews, and support options can help narrow down your choices.

In addition to the machine itself, consider the types of materials you will be printing on. Some DTF printers perform better with certain fabrics, while others may have limitations. It’s beneficial to look for a printer that offers versatility in terms of compatible media to maximize your creative outputs. Also, investing in a model with features that simplify the workflow can significantly enhance your overall printing experience.

Essential Equipment for Successful DTF Transfers

To embark on your DTF transfer journey, you’ll need to gather essential equipment that can ensure a seamless printing process. Start with a dedicated DTF printer; this specialized device is designed to work with DTF inks and films, yielding high-quality outputs. Additionally, obtaining high-grade DTF transfer film is crucial for capturing detailed designs and vibrant colors. Choosing the right equipment might seem overwhelming, but investing in quality components can pay off significantly in the long run.

Moreover, a heat press is an indispensable part of the DTF transfer process, allowing you to apply the heat and pressure necessary to bond the design securely to the fabric. Different heat presses come with varied features, such as adjustable temperature settings and digital timers, which cater to diverse DTF transfer requirements. Assembling a well-rounded toolkit, including cleaning supplies and quality inks, will streamline your workflow and enhance your printing results.

Cost-Effectiveness of DTF Printing Compared to Other Methods

The cost-effectiveness of DTF printing is one of its most appealing attributes, especially for those entering the custom apparel market. Compared to traditional printing techniques like Direct to Garment (DTG) or screen printing, DTF transfers significantly lower both startup and operational costs. With DTF, you can produce high-quality prints on demand without incurring excess material costs, making it an economical choice for small businesses and hobbyists alike.

In addition, DTF printing offers the possibility of smaller runs without compromising quality. This flexibility allows entrepreneurs to test the market with limited quantities before committing to larger orders, reducing waste and ensuring that resources are utilized efficiently. As the trend of personalized apparel continues to grow, embracing a cost-effective printing approach can lead to profitable opportunities.

Tips to Enhance Your DTF Printing Experience

Improving your DTF printing process is all about consistent practice and experimentation. Start by running test prints on varying types of fabrics; this will help determine the best settings for your printer and prevent potential mishaps in larger production runs. Keeping a record of these settings can streamline future projects and increase efficiency in your workflow.

Additionally, routine maintenance of your printer and heat press is paramount in ensuring optimal performance. Regularly clean the printer’s nozzles and print heads to prevent clogs and maintain a high quality of prints. Establishing a quality control process is equally essential, as it ensures that every product meets your standards and helps cultivate customer trust in your brand.

Overcoming Challenges in DTF Printing

While DTF printing offers numerous benefits, it also presents challenges that users must navigate. One of the primary hurdles can be the initial equipment cost, which, despite being lower than other methods, can still feel significant for beginners. Furthermore, the learning curve associated with mastering the temperature and pressure settings on the heat press can lead to trial-and-error moments that can be frustrating.

Another common challenge in DTF printing is material compatibility. Not all fabrics work seamlessly with DTF transfers, which can lead to unsatisfactory results if not properly tested beforehand. Conducting thorough tests across different materials can help identify which options yield the best results, thus enabling you to expand your printing capabilities confidently.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct to Film printing, is a process that involves printing designs onto a specially coated film using DTF inks. Once printed, DTF powder adhesive is applied, and the design is then transferred onto fabric using a heat press. This method allows for vibrant graphics and intricate details, making it popular for custom apparel.

What equipment do I need to start DTF printing?

To start DTF printing, you will need a few essential pieces of equipment: a reliable DTF printer suitable for your needs, DTF transfer film, DTF adhesive powder, and a heat press. Investing in quality equipment ensures better print quality and durability of your designs.

How can I improve my DTF transfer process?

To enhance your DTF transfer process, ensure you use compatible DTF inks and film, maintain your equipment regularly, and run test prints on various fabrics. Adjust the heat press settings according to the material used and follow the manufacturer’s guidelines for best results.

What types of materials are suitable for DTF transfers?

DTF transfers work best on a variety of textiles, including cotton, polyester, and blends. However, it is crucial to test your designs on different fabrics to determine compatibility and achieve optimal adhesion and durability.

What are the advantages of using a DTF printer for custom apparel?

The advantages of using a DTF printer for custom apparel include lower startup costs compared to DTG or screen printing, the ability to produce vibrant colors and detailed designs, and the flexibility to print on-demand, which reduces waste and inventory costs.

Can I transfer DTF prints onto dark fabrics?

Yes, DTF printing is versatile and can be used on dark fabrics. When using DTF transfers on darker materials, ensure that the design is properly set up with vibrant colors to ensure the best visibility and quality of the finished print.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | A printing solution for transferring designs onto textiles with vibrant colors and details. |

| Cost-Effectiveness | Lower startup costs compared to DTG or screen printing, ideal for small businesses. |

| Essential Equipment | DTF Printer, DTF Transfer Film, Heat Press are necessary for the process. |

| Understanding Materials | DTF Inks and Powder Adhesive are crucial for adhesion and quality. |

| Transfer Process Steps | Create design, print on DTF film, apply adhesive, cure, and transfer to fabric. |

| Choosing a DTF Printer | Select models with good reviews, like the Prestige A4, based on your needs. |

| Enhancing Your Experience | Run test prints, maintain equipment and implement quality control processes. |

| Challenges | Equipment costs, learning curve, material compatibility issues. |

Summary

DTF transfers are an innovative way to customize apparel, providing incredible detail and vibrant colors for various textiles. Understanding the basics of DTF printing, from the necessary equipment to the step-by-step transfer process, is essential for anyone looking to delve into this creative field. Quality materials and proper maintenance are key to successful printing, ensuring each design resonates with customers. As you explore the exciting world of DTF transfers, remember to embrace the learning process and let your artistic vision flourish.