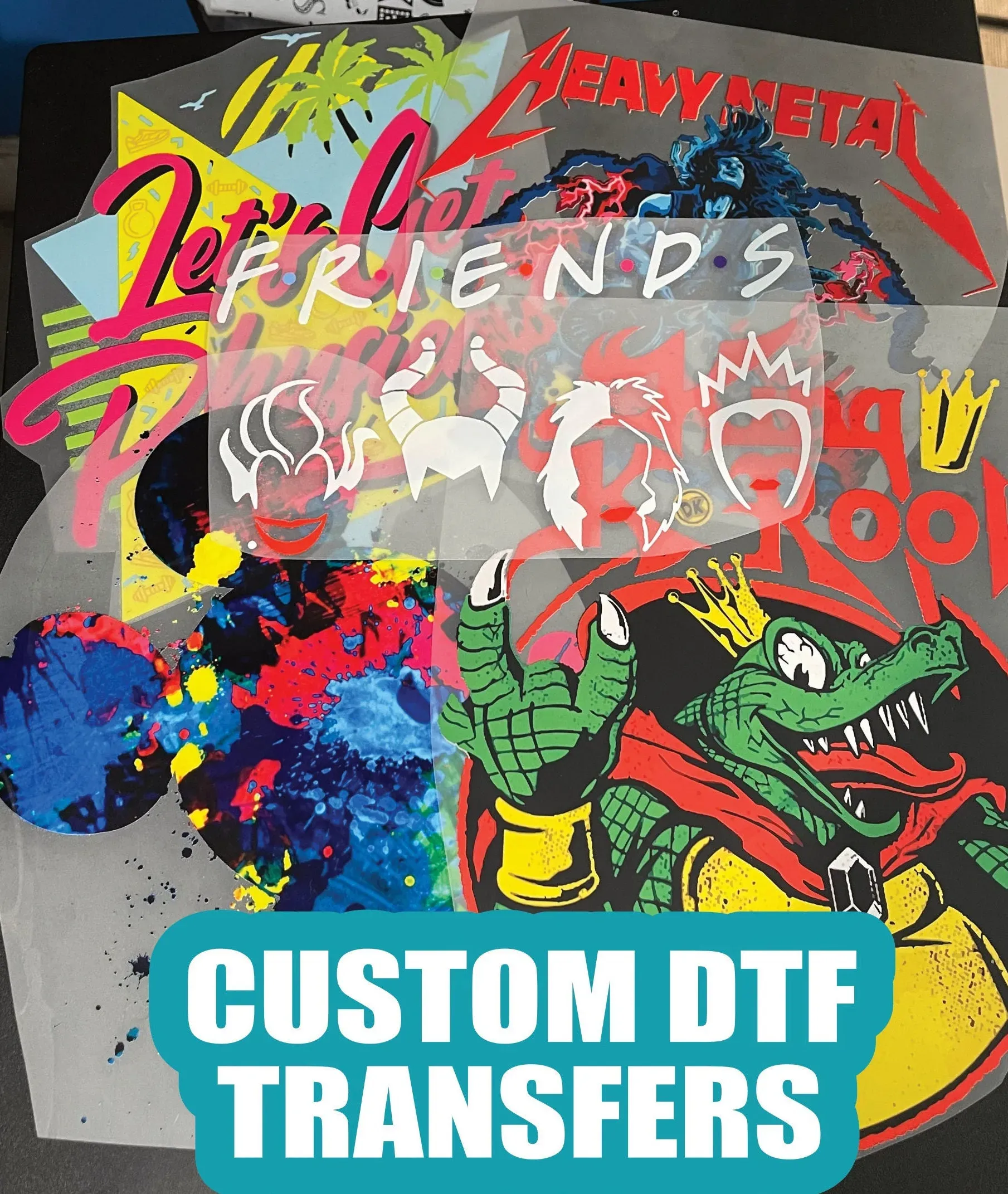

In the realm of custom apparel printing, DTF transfers have emerged as a groundbreaking technology that’s reshaping how designs are applied to fabrics. This innovative method, known as Direct to Film printing, enables vibrant, high-quality transfers that adhere to various materials with remarkable durability. Entrepreneurs and small business owners are increasingly turning to DTF printing technology for its versatility and efficiency, allowing them to produce stunning designs that resonate with consumers. With the advent of print on demand services, DTF transfers pave the way for personalized fashion, giving creators the freedom to craft unique pieces without the burden of large inventory. Discover how you can leverage a reliable DTF transfer service to elevate your brand and captivate your audience.

When it comes to the art of custom garment decoration, Direct to Film (DTF) transfers stand out as a premier choice for many designers and small businesses. This advanced printing technique, often referred to as film transfers, empowers users to achieve exceptional color vibrancy and sharp detail on a wide array of fabrics. The advent of DTF technology has sparked a revolution in custom apparel solutions, allowing entrepreneurs to enter the market with flexible print on demand options. Not only do these film-based prints provide a durable finish, but they also cater to the growing demand for personalized apparel. Whether you call it DTF printing or film-based printing, the benefits remain the same—unmatched quality and creativity in custom apparel production.

Understanding the Basics of DTF Transfers

DTF transfers, or Direct to Film transfers, represent a significant advancement in the printing landscape, especially for custom apparel printing. This technique transforms designs into vibrant prints that can be applied to a variety of fabrics using a heat press. Unlike traditional methods, DTF allows for intricate designs with full-color vibrancy to be replicated with ease and precision. As small business owners explore the world of garment decoration, understanding the mechanics of DTF printing technology can open doors for greater creativity and profitability.

The DTF printing process starts with preparing your artwork and then printing it onto a special film that carries the design. The addition of adhesive powders that bond during the heat transfer process results in prints that are not only vibrant but also durable. This innovative method greatly enhances the possibilities for custom apparel, allowing businesses to offer diverse products without compromising quality.

The Growing Popularity of DTF Printing Technology

The surge in popularity for DTF printing technology can be attributed to its versatility and efficiency. Small businesses looking for custom solutions can benefit significantly from DTF transfers as it enables them to produce high-quality apparel without the need for large-scale printing setups. This is particularly impactful for those working in the print on demand sector, where quick turnaround times and flexibility are essential.

Moreover, the ease of use associated with DTF technology makes it an attractive option for entrepreneurs who may not have extensive printing backgrounds. With the right guidance, even beginners can achieve professional results, bolstering their capacity to compete in an increasingly crowded market.

Latest Innovations in DTF Transfers

Recent advancements in DTF transfer technology are transforming how businesses operate in the custom apparel industry. Companies like Sam’s DTF Transfers and Insta Graphic Systems are leading the charge with innovative solutions that promise faster production times and more vibrant prints. Such advancements not only enhance product offerings but address the changing needs of consumers, who are increasingly seeking unique and personalized fashion.

These innovations highlight the industry’s shift towards embracing efficiency while maintaining high-quality standards. For print service providers, investing in updated DTF equipment and procedures ensures they remain competitive and equipped to meet the evolving demands of their clientele.

Best Practices for Applying DTF Transfers

Once you’ve procured your DTF transfers, applying them correctly is crucial for achieving the best results. A project begins with careful design preparation and printing, but the applied technique is what determines the longevity and appearance of the final product. Ensuring that the right temperature and pressure are maintained during the heat transfer process is vital for the adhesive to bond correctly and achieve a soft finish.

Additionally, familiarizing oneself with the specific requirements of different fabrics can aid in making informed decisions about the types of DTF transfers to use. Each fabric has unique properties that can affect how a transfer adheres, so experimenting with test samples can provide insights into optimizing the application process.

Choosing the Right DTF Transfer Services

Selecting the best DTF transfer service for your business involves thorough research and understanding your specific needs. It’s essential to look for suppliers that offer high-quality materials, reliable customer service, and rapid turnaround times. Reading reviews and asking for samples can help determine the legitimacy and quality of service provided.

Moreover, exploring a supplier’s experience with different types of custom apparel printing can provide reassurance that they can meet your unique requirements. Opting for a transfer service that offers additional support or training can be beneficial, especially for new users venturing into the world of DTF technology.

The Future of Custom Apparel with DTF Transfers

As DTF printing technology matures, the future of custom apparel appears bright. The ongoing developments aim to enhance user experience, innovative designs, and improve product durability. This evolution aligns with the ever-increasing consumer demand for unique and personalized pieces, positioning DTF technology as a go-to solution for many apparel businesses.

Furthermore, the trends suggest a movement towards sustainability within the industry, with businesses seeking eco-friendly alternatives in materials and methods. As DTF technology continues to adapt, it will likely offer environmentally sustainable solutions, appealing to a more conscious consumer base while maintaining the aesthetic quality that drives the custom apparel market.

Frequently Asked Questions

What are DTF Transfers and how do they work in custom apparel printing?

DTF Transfers, or Direct to Film transfers, involve printing designs onto a special film that can be heat pressed onto various fabrics. The process starts with a DTF printer that applies ink onto the film, followed by a hot melt adhesive powder. After curing the powder, the film is then heat pressed onto the garment, resulting in vibrant, durable prints ideal for custom apparel.

Why should I choose DTF printing technology over other custom apparel printing methods?

DTF printing technology offers several advantages over traditional methods like screen printing or heat transfers. It allows for high-quality full-color prints on a variety of fabrics, is faster in production time, and requires less setup, making it perfect for print on demand services. Additionally, DTF transfers are more durable and softer to the touch, enhancing the overall quality of custom apparel.

How do I find a reliable DTF transfer service for my printing needs?

To find a reliable DTF transfer service, research suppliers with positive reviews in the custom apparel printing sector. Look for websites and craft blogs that recommend reputable suppliers. Check for sample prints to assess quality, and ensure the supplier understands specific needs, such as custom designs, delivery times, and provides adequate support.

What advancements are currently being made in the DTF transfer industry?

The DTF transfer industry is witnessing rapid advancements, such as the introduction of new products by companies like Insta Graphic Systems that enhance color vibrancy and durability. Additionally, services like Sam’s DTF Transfers are launching in-house services to cater to small businesses, making custom apparel more accessible. New platforms are also emerging, providing flexible, equipment-free DTF printing solutions to meet growing demand.

What are some tips for successfully applying DTF transfers to garments?

To successfully apply DTF transfers, ensure that your design is high-resolution and compatible with your fabric type. Follow a precise heat transfer process by setting the appropriate temperature and pressure on your heat press. Additionally, pre-press the fabric to remove moisture and wrinkles before applying the transfer to enhance adhesion and finish quality.

Can I use DTF transfers for all types of fabrics in custom apparel?

Yes, DTF transfers can be used on a wide range of fabrics, including cotton, polyester, and blends. This versatility makes DTF printing technology a popular choice for custom apparel, as it achieves vibrant results on different material types. However, be sure to follow specific guidelines for each fabric to optimize print quality and durability.

| Key Points | Details |

|---|---|

| Introduction to DTF Transfers | DTF transfers allow vibrant, high-quality prints on various fabrics, essential for custom apparel. |

| Process of DTF Transfers | Involves printing on a film, applying adhesive powder, and heat pressing onto fabric, resulting in durable prints. |

| Recent Innovations | Companies like Sam’s DTF Transfers and Insta Graphic Systems are developing in-house services and enhanced printing products. |

| Market Accessibility | New platforms such as Snuggle offer flexible solutions for custom printing without heavy investments. |

| Purchasing Tips | Research suppliers, check quality, understand your needs, consider delivery times, and seek support. |

Summary

DTF transfers have emerged as a groundbreaking solution in the custom apparel industry, revolutionizing how designs are printed and applied to fabrics. This method stands out due to its ability to deliver vibrant, durable prints while being accessible to small businesses. As the DTF technology continues to advance, entrepreneurs can confidently adopt this printing method, knowing they have various options and resources available to them. Understanding the nuances of DTF transfers, from the printing process to selecting the right suppliers, allows business owners to create unique and eye-catching apparel that meets the demands of their clients and the market. With the right tools and knowledge, the possibilities with DTF transfers are limitless.