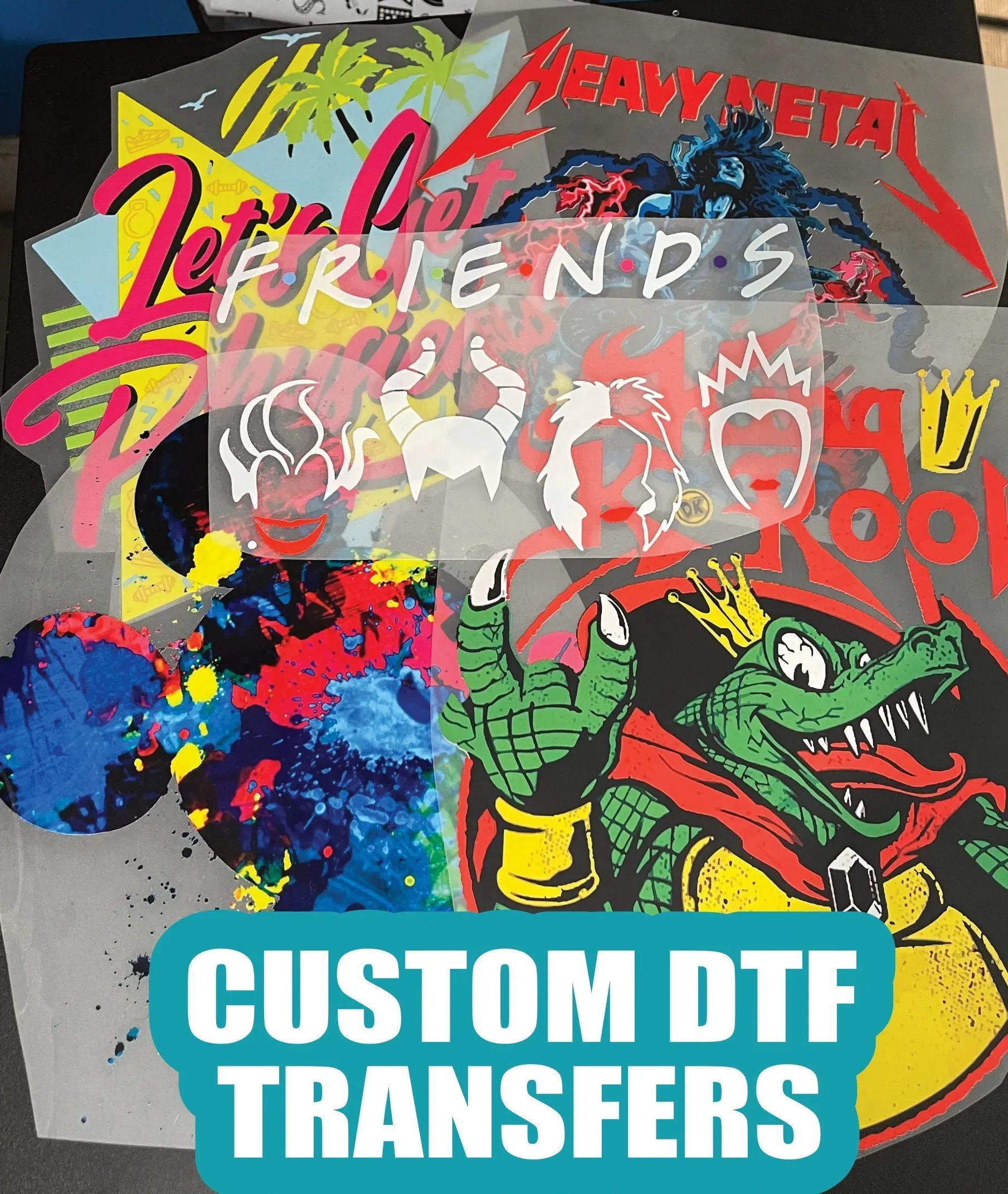

DTF transfers, or Direct to Film transfers, have taken the textile printing industry by storm, revolutionizing the way designers approach garment decoration. This innovative process utilizes cutting-edge DTF printing techniques that apply vibrant graphics onto fabric for stunning results. With the right adhesive powder for DTF, you can achieve a flawless bond that ensures your designs are not only striking but also durable. Understanding the best fabrics for DTF will help you harness the full potential of this method, producing merchandise that stands out. Join us as we delve into essential DTF printing tips, equipping you with the knowledge to excel in creating eye-catching designs.

Direct to Film printing is an exciting advancement in the fabric decoration world, streamlining the transfer of intricate designs onto textiles. This method, often referred to as DTF printing, allows for a wide range of color applications and works across various fabric types. By integrating adhesive powder designed specifically for DTF processes, users can ensure a solid adherence of prints, contributing to their longevity and vibrancy. Moreover, understanding which fabrics are most compatible with DTF techniques can make all the difference in the quality of the final product. In this guide, we will explore the fundamentals of DTF transfers and share valuable insights to enhance your printing capabilities.

Understanding DTF Printing Techniques

DTF printing, or Direct to Film printing, has revolutionized the textile industry by allowing designers to create eye-catching graphics that are both vibrant and durable. This method utilizes a specialized film to print designs directly, which can then be transferred onto a variety of fabrics. By harnessing advanced ink technology, DTF transfers enable intricate detailing that traditional printing methods struggle to achieve. The process is not only efficient but also adaptable for small and large-scale productions, making it a preferred choice among custom apparel decorators.

One of the standout features of DTF printing techniques is their compatibility with different fabrics. Unlike other printing methods that may work best on cotton or polyester, DTF can equally perform well on blends and other synthetic materials. This versatility empowers designers and businesses to cater to a wider audience by offering diversity in product options. Understanding these techniques is crucial for maximizing the potential of your designs and ensuring that your creations are both stunning and marketable.

Essential Tips for Applying Adhesive Powder for DTF

The application of adhesive powder is a critical component in the DTF transfer process. To guarantee a successful transfer, it is essential to apply the adhesive while the ink is still wet. Ensuring that the adhesive evenly covers the design allows for a stronger bond during the heat transfer process. This step cannot be rushed; sprinkle a sufficient amount of powder so that it adheres properly to the ink, and then utilize a heat gun to promote even melting. This not only improves the adherence of the ink to the fabric but also contributes to the longevity of the design.

Moreover, using the right type of adhesive powder can greatly impact the final result of your DTF transfers. There are various brands available, and selecting one that suits the specifics of your ink and fabric can make a significant difference in vibrancy and durability. It’s also crucial to be aware of the environmental conditions, as humidity and temperature can affect how the adhesive behaves. Experimenting with different powders and techniques can yield insights that help you refine your process and achieve consistent, high-quality results.

Choosing the Best Fabrics for DTF Transfers

Selecting the right fabric is integral to the success of your DTF transfers. Fabrics that are composed of polyester or blends that include synthetic fibers tend to yield the best results due to their ability to absorb ink well, resulting in vibrant color output. These materials also provide excellent durability, allowing colors to withstand multiple washes without significant fading. Working with cotton alone may not produce the desired vibrancy, hence exploring polyester blends can be beneficial for optimal designs.

Additionally, it’s wise to test various fabric types, especially if you’re interested in branching out beyond standard offerings. Non-traditional fabrics like canvas or certain wovens may also be suitable if prepared properly. Ensure that you adjust your printing settings accordingly for each fabric type to maximize adhesion and durability of the DTF transfers. By conducting thorough fabric tests, you can identify the best options for your specific projects, leading to more successful and visually appealing outcomes.

Importance of Proper Curing Techniques

Curing plays a pivotal role in the effectiveness of DTF transfers, ensuring that your designs adhere properly and remain vibrant over time. Properly curing the adhesive powder bonds the ink to the fabric, preventing peeling and fading. It’s crucial to follow the recommended temperature and time settings specified for both the film and inks being used. This guarantees that every design is treated uniformly during the transfer process, ultimately contributing to the longevity of your finished product.

Furthermore, investing in a high-quality heat press can make a noticeable difference in your curing results. Equipment that accurately maintains temperature and pressure settings is essential for achieving optimal curing results. Avoiding alternative heat sources such as household irons can lead to inconsistencies in pressure and temperature, undermining the integrity of your designs. By focusing on the curing process, you ensure that your DTF transfers are not only visually appealing but also robust enough for everyday wear.

Optimizing Your Designs for DTF Printing

When designing graphics for DTF printing, it’s essential to consider the unique properties of the process. An important tip is to avoid overly intricate designs; while DTF allows for detailed imagery, complex patterns may not transfer well or could compromise the overall quality of the print. Instead, focus on bold, vibrant colors and simple layouts that stand out and are easily recognizable. Utilizing high-resolution files is also crucial to avoid pixelation, ensuring your designs come out crisp and clear.

Additionally, think about the color profiles you are using. Since DTF printing can recreate a wide color spectrum, using RGB color settings can enhance the richness of your design. Test out different combinations to see what gives the most vibrant result. By optimizing your designs with these considerations in mind, you give your DTF transfers the best potential to captivate audiences with their quality and vibrancy.

Post-Transfer Care Tips for Longevity of DTF Transfers

Caring for your DTF printed garments is just as important as the printing process itself. Proper post-transfer care can significantly extend the life of your designs. For instance, avoid washing the garments in hot water and opt to wash inside out to prevent abrasion against other fabrics. Furthermore, steering clear of bleach and harsh detergents is essential to maintain the integrity of the inks and prevent fading. By establishing these care routines, you can help your designs retain their freshness and vibrancy over time.

It’s also beneficial to follow specific drying methods, such as air drying instead of machine drying, to avoid damaging the print. Heat from dryers can weaken the adhesive bond over time, leading to peeling or cracking of the design. Informing customers about these care instructions when selling DTF printed items can enhance user satisfaction and assurance, knowing they are taking the best steps to preserve their unique designs.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF transfers, or Direct to Film transfers, involve printing designs onto a special film using DTF printing techniques, applying adhesive powder, and then heat pressing the design onto fabrics. This method promotes vibrant colors and intricate details that adhere well to various materials.

What is the best type of fabric for DTF printing?

When it comes to DTF printing, polyester blends are often considered the best fabrics. They enhance color vibrancy and durability, allowing for high-quality DTF transfers. Testing different fabrics can help identify the optimal choice for your particular designs.

How do I properly apply adhesive powder for DTF transfers?

To achieve the best results in DTF transfers, immediately sprinkle adhesive powder on the wet ink right after printing. Ensure the powder covers evenly and then use a heat gun to melt it, ensuring a strong bond between the ink and fabric for long-lasting designs.

What are some essential tips for successful DTF printing?

Key tips for successful DTF printing include using high-quality materials, optimizing printer settings, selecting the right adhesive powder, ensuring proper curing with the heat press, and maintaining simple yet vibrant designs. Care for your printed fabrics is also crucial for longevity.

How should I care for garments printed with DTF transfers?

To extend the lifespan of your DTF transfers, wash garments inside out using mild detergents, and avoid bleach or harsh chemicals. Following these care instructions will help keep your designs looking fresh and vibrant through multiple washes.

Why is continuous learning important in DTF printing?

Continuous learning is vital in DTF printing due to the evolving nature of techniques and materials. Staying updated through industry blogs, forums, and tutorials can enhance your skills, helping you adapt to new discoveries and improve your DTF transfers and designs.

| Tip | Description |

|---|---|

| Quality of Materials | Select high-quality DTF film and inks to enhance vibrancy and durability. |

| Printer Settings | Adjust printer settings for resolution and color profiles to optimize DTF printing. |

| Use of Adhesive Powder | Sprinkle adhesive powder onto wet ink and use a heat gun to bond it effectively. |

| The Curing Process | Follow recommended temperature and timing for effective curing to ensure durability. |

| Fabric Selection | Choose polyester blends for vibrant colors and durability during washing. |

| Optimize Your Designs | Use vibrant colors and high-resolution files. Avoid overly intricate designs. |

| Post-Transfer Care | Wash garments inside out and avoid harsh detergents to maintain print quality. |

| Continuous Learning and Improvement | Stay updated on DTF techniques through blogs, forums, and tutorials. |

Summary

DTF transfers are a transformative technique in textile printing, merging creativity and technology to produce stunning designs. Understanding the fundamentals of DTF transfers is crucial for achieving remarkable results. By focusing on elemental aspects like the quality of materials, printer settings, and proper post-transfer care, anyone can significantly improve their output quality. Mastering DTF transfers not only enhances your design capabilities but also opens countless avenues in the textile industry. Embrace this innovative method and let it propel your artistic endeavors to new heights!