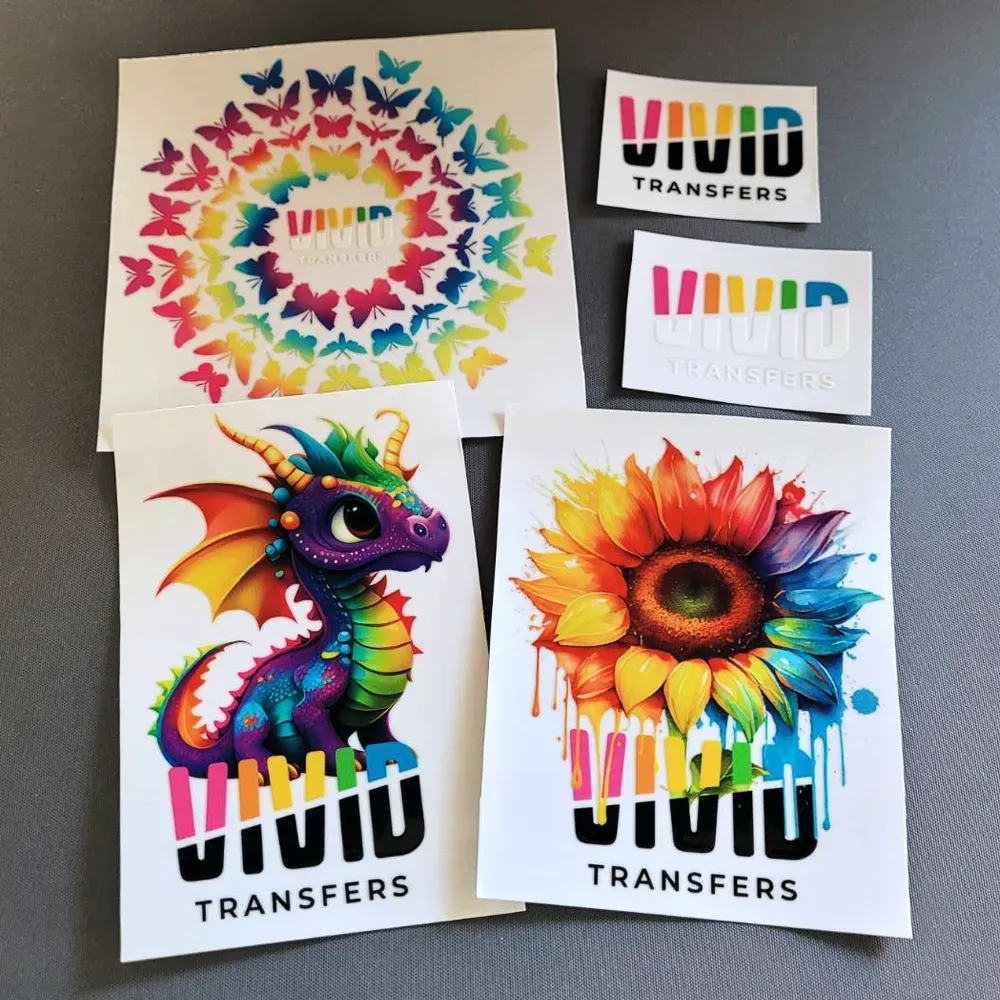

UV DTF designs are revolutionizing the world of printing, bringing forth unparalleled quality and vibrancy that captivates audiences. With the capability to produce high-quality prints, this innovative technique employs advanced DTF printing methods that blend durability with stunning visual appeal. Whether you’re a seasoned designer or a business owner, understanding the nuances of UV printing can significantly elevate your projects. The key lies in maximizing print quality through meticulous attention to materials, techniques, and equipment maintenance. In this article, we’ll delve into essential design tips for prints that will help you harness the full potential of UV DTF designs.

When exploring the realm of DTF print technology, one can encounter various terms synonymous with UV DTF designs, including UV transfer printing and digital film transfer processes. This cutting-edge approach employs UV inks that adhere seamlessly to substrates, yielding striking images that stand the test of time. The vital aspect here is the incorporation of high-resolution outputs and careful material selection, which can dramatically enhance the final results. By analyzing DTF techniques and exploring alternatives, designers can uncover creative opportunities that lead to mesmerizing, long-lasting prints. Embrace these innovative printing solutions to elevate your design projects and achieve remarkable results.

The Advantages of UV DTF Printing

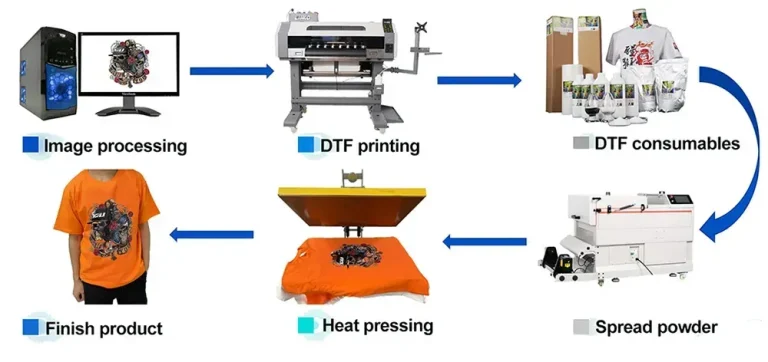

UV DTF printing offers numerous advantages that distinguish it from traditional printing methods. Firstly, this innovative technique utilizes UV-curable inks that dry quickly upon exposure to ultraviolet light. This not only enhances the production speed but also allows for high-resolution images with rich, vivid colors. Additionally, UV inks are incredibly durable, providing resistance to fading, scratching, and washing, making them suitable for a variety of substrates, from fabric to rigid materials.

Furthermore, UV DTF printing supports eco-friendliness as it minimizes volatile organic compounds (VOCs) and has a lower carbon footprint compared to other print processes. The versatility of this printing method enables designers to experiment with intricate prints and textures that stand out in the market. This increased durability and vibrant output can ultimately lead to greater customer satisfaction and repeat business.

Choosing the Right Materials for Your UV DTF Designs

Selecting the right materials is fundamental to achieving high-quality UV DTF prints. High-grade films designed specifically for DTF applications are essential as they significantly improve ink adhesion and printing clarity. By using superior films, designers can enhance their chances of creating highly detailed graphics that maintain their quality over time.

Additionally, the choice of inks plays a crucial role in the printing process. Opting for high-performance UV inks ensures that your prints not only have vibrant colors but also demonstrate excellent durability. Inks formulated for UV DTF printing can withstand environmental factors such as light exposure and abrasion, ultimately resulting in longer-lasting prints that meet customer expectations.

Maximizing Print Quality Through Optimization

To maximize the print quality of UV DTF designs, optimizing printer settings is a critical step. Setting your printer to a higher DPI, such as 1200 DPI, captures intricate details better, resulting in sharper, more vibrant prints. This is especially important for complex designs where every detail matters to maintain visual integrity.

Moreover, using the correct color profiles is vital for ensuring the print accurately reflects what you’ve designed digitally. Mismatches between screen colors and printed colors can lead to disappointing results, so employing specific color profiles designed for your inks and films can eliminate discrepancies, leading to a more faithful representation of your vision.

The Importance of Proper Fabric Pre-Treatment

Pre-treating fabrics is an often overlooked but essential process for enhancing print quality in UV DTF designs. By applying a suitable pre-treatment, you improve the fabric’s ability to bond with the ink, which minimizes the chances of peeling or fading over time. Different fabric types may require different pre-treatment solutions, making it key to select the right one based on your substrate.

This crucial step ensures that the ink penetrates the fabric correctly, thereby enhancing adhesion and longevity. Additionally, failing to pre-treat may lead to inconsistent print results, further emphasizing the need for this preparatory action in the printing process.

Ensuring Durability with Proper Curing

Curing is a fundamental process in UV DTF printing that greatly impacts the durability of prints. Properly curing your prints using either a heat press or UV light solidifies the ink and ensures it bonds effectively, making the end product streak-resistant and long-lasting. Depending on the type of ink and film used, selecting the proper curing method becomes essential in achieving optimal results.

Furthermore, improper curing can lead to issues such as ink smudging or premature wear, adversely affecting the print quality. Regularly calibrating and maintaining curing equipment ensures consistent results, contributing significantly to the overall longevity of your UV DTF prints.

Essential Maintenance for Quality Equipment Performance

Maintaining printing equipment is crucial for sustaining high-quality output in UV DTF designs. Regular cleaning of print heads and components is essential to prevent dust and ink build-up that can lead to streaks and diminished print quality. By incorporating a routine cleaning schedule, you can enhance the performance and longevity of your printer.

In addition to cleaning, keeping an eye on ink cartridges is equally important. Regularly checking ink levels and replacing expired or low-quality inks can protect against compromised print quality. Ensuring equipment maintenance is part of your workflow will ultimately reduce downtime and enhance the reliability of your printing operations.

Frequently Asked Questions

What are the key benefits of using UV DTF designs for printing?

UV DTF designs offer several advantages, including vibrant colors and high detailing of prints. This printing technique utilizes UV inks adhered to a special film, leading to durable designs that resist fading and wear, making them suitable for a variety of substrates.

How can I maximize print quality with UV DTF designs?

To maximize print quality with UV DTF designs, ensure you use high-grade films and quality UV inks. Additionally, optimize your printer settings to a higher DPI, pre-treat fabrics appropriately, and follow a proper curing process to enhance ink adhesion and durability.

What design tips should I consider for high-quality UV DTF prints?

For high-quality UV DTF prints, utilize vector images whenever possible, as they preserve quality at any size. It’s also crucial to design using the CMYK color model for better color accuracy in print and ensure images are at least 300 DPI for clarity.

What is the role of equipment maintenance in UV DTF printing quality?

Proper equipment maintenance is vital for maintaining UV DTF printing quality. Regularly clean print heads and monitor ink cartridges to prevent streaks or performance issues. A well-maintained printer ensures consistent quality across multiple prints.

How does the curing process impact UV DTF designs?

The curing process greatly impacts UV DTF designs by solidifying the ink, enhancing adhesion, and ensuring prints are streak-resistant. Depending on the ink type, use either a heat press or UV light to effectively cure the prints for maximum durability.

What should I know about optimizing printer settings for UV DTF designs?

Optimizing printer settings for UV DTF designs is crucial for achieving high-quality prints. Set the printer to a minimum of 1200 DPI to capture details accurately and use the correct color profiles tailored to your specific inks and films to avoid discrepancies in color.

| Key Point | Details |

|---|---|

| Understanding UV DTF Printing | UV DTF printing uses UV inks on special films to produce vivid and durable designs on various substrates. |

| 1. Choose Quality Materials | Invest in high-grade films and UV inks for better ink adhesion and image precision. |

| 2. Optimize Printer Settings | Set a higher DPI (1200 DPI) and use correct color profiles to ensure print accuracy. |

| 3. Pre-Treatment of Fabrics | Utilize specific pre-treatment solutions to enhance ink bonding on fabrics. |

| 4. Proper Curing Process | Use heat press or UV light to properly cure prints for longevity. |

| 5. Maintenance of Equipment | Regularly clean components and check ink cartridges to maintain print quality. |

| 6. Test Prints and Calibration | Conduct test runs and calibrate printers to ensure consistent print quality. |

| 7. Design Considerations | Use vector images and the CMYK color model for optimal printing outcomes. |

Summary

UV DTF designs can significantly enhance the quality of your printed materials by following certain best practices. By understanding the fundamentals of UV DTF printing and implementing tips such as selecting quality materials, optimizing printer settings, and performing regular equipment maintenance, you can achieve vibrant and durable prints. Additionally, pre-treatment of fabrics and careful curing methods play crucial roles in ensuring that your designs last over time. Testing your prints and ensuring proper calibration will help maintain quality across productions. In a constantly evolving industry, staying updated with the latest techniques and materials is essential for success in UV DTF designs.