DTF Transfers, or Direct-to-Film transfers, have revolutionized the world of custom apparel printing, allowing for stunning and vibrant designs to be printed on a variety of fabrics. As businesses and individuals alike seek high-quality and personalized print solutions, DTF transfer technology has emerged as a frontrunner in effective heat transfer technology. This innovation not only simplifies the printing process but also opens doors for unparalleled creativity in clothing design. In this guide, we’ll delve into the essential techniques and tools essential for mastering DTF printing, ensuring your prints are nothing short of exceptional. By embracing DTF transfer techniques, you’ll position yourself at the forefront of a competitive industry, ready to meet the ever-growing demand for unique apparel.

Exploring the realm of Direct-to-Film printing, often known as DTF transfer printing, unveils a fascinating approach to apparel decoration that provides vibrant and intricate designs. This advanced method leverages modern heat transfer technology to create durable prints that can adapt to various fabric types, making it an attractive option for custom clothing and merchandise. Within this article, we will highlight essential DTF printing tools and techniques that help producers consistently achieve high-quality results. As we navigate the innovations surrounding DTF transfers, you’ll discover how this printing process can elevate your creative output in the competitive landscape of custom apparel. Utilizing alternative terms such as heat transfer film applications underlines the versatility and effectiveness of this dynamic printing method.

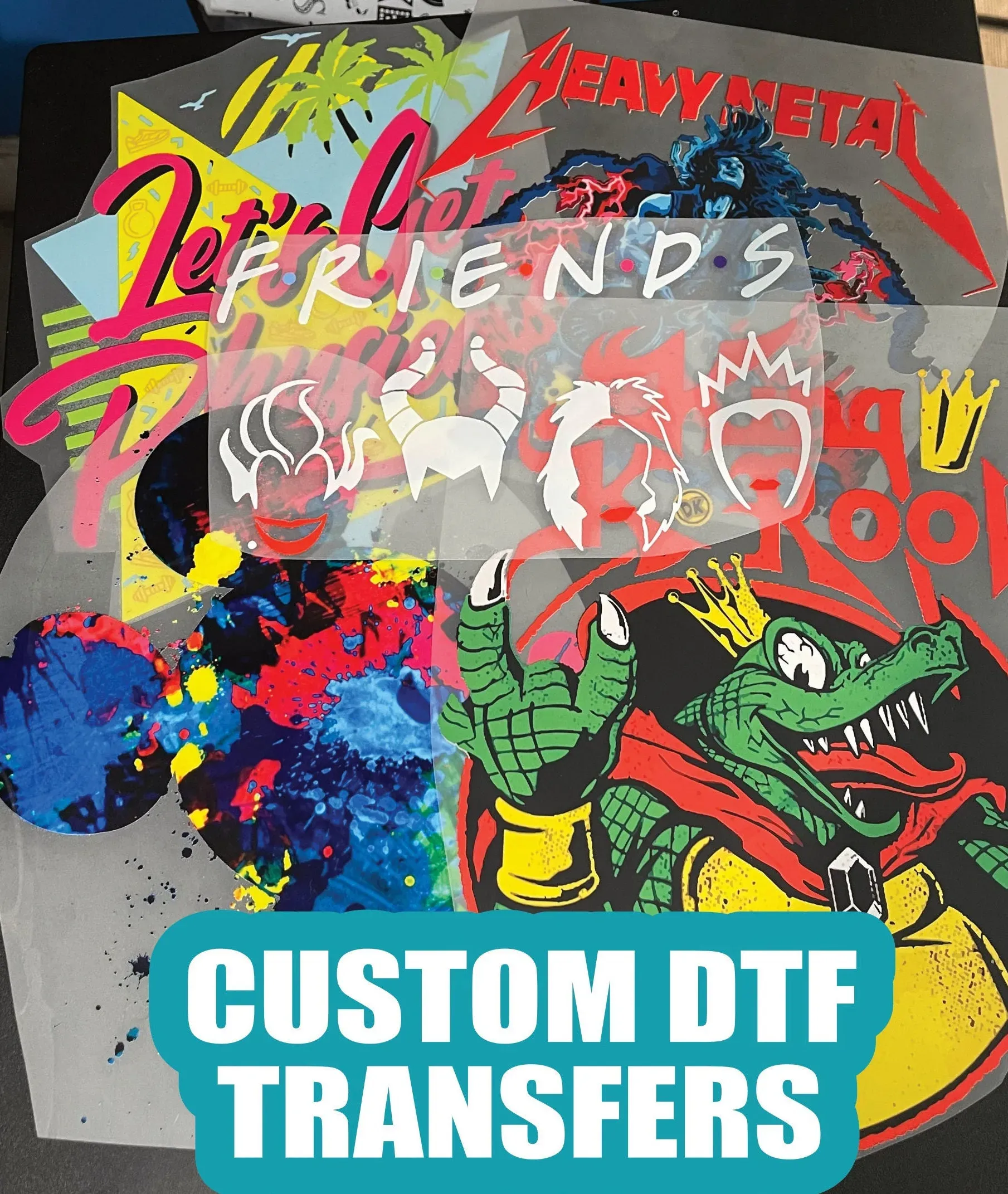

The Advantages of DTF Transfers in Custom Apparel

DTF transfers have quickly risen to prominence in the custom apparel space due to their exceptional vibrancy and versatility. This method allows for intricate designs that maintain clarity and color saturation on various fabric types, including cotton, polyester, and blends. The technology lets businesses create intricate images and graphics that are perfect for personalizing clothing, making it an attractive option for both large-scale production and small, bespoke orders.

Moreover, DTF printing excels in efficiency. Unlike traditional screen printing, which can be labor-intensive and time-consuming, DTF transfers streamline the production process. This efficiency not only reduces turnaround times for clients but also allows businesses to adjust quickly to changing market demands, providing a competitive edge in the ever-evolving landscape of custom apparel.

Essential DTF Transfer Techniques for Success

To achieve success with DTF transfers, businesses must adopt effective techniques that optimize the printing process. A key technique is mastering the application of heat and pressure, which are critical in ensuring designs adhere properly to fabrics without compromising quality. This includes understanding the specific requirements of different materials to achieve optimal results.

Another important aspect is the use of high-quality DTF printing tools. Investing in specialized printers that are compatible with DTF inks is essential for producing durable and vibrant prints. These tools, combined with the right techniques, ensure that the final products not only meet but exceed expectations, delivering high satisfaction for both businesses and customers.

Understanding DTF Printing Tools and Equipment

The backbone of any successful DTF operation lies in the right tools and equipment. Quality printers that are specifically designed for DTF applications play a critical role in maintaining print clarity and color quality. These machines should support specialized DTF inks that enhance durability and vibrancy, ensuring that the final product stands out.

In addition to printers, heat press machines are vital for DTF success. The selection of adequate heat press equipment that delivers consistent heat and pressure can significantly impact transfer quality. A well-constructed heat press with adjustable settings allows for the delicate handling of diverse fabrics, crucial for achieving professional results across different applications.

The Role of Advanced Technology in DTF Transfers

The advancement of heat transfer technology has significantly influenced DTF transfers, allowing for enhanced durability and print quality. Companies like Insta Graphic Systems have pioneered the use of innovative heat transfer products that not only improve print aesthetics but also prolong the longevity of designs on garments. This trend showcases a commitment to leveraging technology in ways that meet and exceed customer expectations.

Furthermore, integrating state-of-the-art printing techniques and tools provides businesses with the opportunity to create unique, high-quality products. Staying abreast of these technological innovations enables companies to maintain a competitive advantage, ensuring they can offer the latest and greatest in DTF transfer capabilities to their clientele.

Catering to Varied Client Needs with DTF Transfers

In the world of custom apparel printing, understanding and catering to diverse client needs is paramount for success. DTF transfers offer a variety of services that can adapt to large companies as well as small businesses, making it a flexible choice in an increasingly competitive market. By recognizing and addressing these varying requirements, businesses can position themselves as go-to providers for all custom printing needs.

Offering tailored solutions, including the ability to handle bulk orders or smaller, individualized requests, provides customers with the flexibility they desire. This model not only fosters long-term relationships with clients but also helps businesses to expand their reach and maintain a steady stream of orders in a fluctuating marketplace.

Future Trends in DTF Transfer Technology and Services

The future of DTF transfers is poised for evolution as new trends continue to emerge. With advances in printing technology and heat transfer methods, businesses can expect to see improved print quality and operational efficiency. The integration of more environmentally friendly inks and processes is also likely to shape the industry’s landscape, catering to a growing market of eco-conscious consumers.

Additionally, as demand for personalization rises, innovations in DTF transfer services will enable businesses to offer even more customized solutions. This may include enhanced options for individualized designs, quick turnaround times, and diverse product offerings that can accommodate various markets, thereby ensuring continued growth and sustainability within the industry.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film transfers, are a printing method where vibrant designs are printed onto a special film, which is then transferred to fabric using heat and pressure. This technology allows for high-quality, detailed prints on various materials, making it ideal for custom apparel printing, especially for cotton and polyester fabrics.

What are the advantages of using DTF printing over traditional methods?

DTF printing offers several advantages over traditional printing methods, including the ability to produce vibrant, high-quality images on diverse fabrics. It allows for quicker production times and eliminates the need for screens, making it more cost-effective for custom apparel printing, especially for small batches.

What kind of tools are essential for successful DTF transfers?

Successful DTF transfers require specific tools, including high-quality DTF printers compatible with specialized inks, reliable heat press machines for effective transfer, and the right type of film and adhesives that enhance vibrancy and durability of the prints.

How can businesses improve their DTF transfer techniques?

Businesses can improve their DTF transfer techniques by adopting in-house printing to maintain quality control, integrating advanced technologies to enhance print vibrancy and durability, and understanding diverse customer needs to provide tailored solutions in the custom apparel market.

What trends are emerging in the DTF transfer industry?

Emerging trends in the DTF transfer industry include advancements in heat transfer technology, the introduction of innovative DTF printing tools, and a shift towards in-house printing services that improve quality control and turnaround times, as seen with companies like Sam’s DTF Transfers.

What is the significance of heat press technology in DTF printing?

Heat press technology is crucial in DTF printing as it ensures consistent application of temperature and pressure needed to effectively transfer designs from film to fabric. A reliable heat press machine can significantly enhance the quality and durability of the final prints.

| Category | Details |

|---|---|

| Definition | DTF (Direct-to-Film) transfers involve printing designs on a special film which is then transferred to fabrics using heat and pressure. |

| Advantages | Produces vibrant, detailed prints on a variety of fabrics, outperforming traditional methods. |

| Key Players | 1. Sam’s DTF Transfers – Focused on quality and rapid service. 2. Insta Graphic Systems – Introduced innovative heat transfer products. |

| Success Techniques | 1. In-house printing for quality control. 2. Advanced technology integration. 3. Understanding diverse client needs. |

| Essential Tools | 1. Quality printers and inks. 2. Adequate heat press equipment. 3. Proper film and adhesives. |

Summary

DTF Transfers are revolutionizing the custom apparel industry, offering vibrant designs and exceptional quality. As the demand for personalized prints grows, understanding the nuances of DTF transfers becomes imperative for success. By leveraging in-house printing, integrating advanced technologies, and recognizing the diverse needs of customers, companies can significantly enhance their service offerings. Additionally, equipping oneself with the right printers, heat press equipment, and films ensures top-notch results. Whether you’re an established player or a newcomer to this flourishing sector, embracing these practices will set the foundation for thriving in the competitive landscape of DTF Transfers.