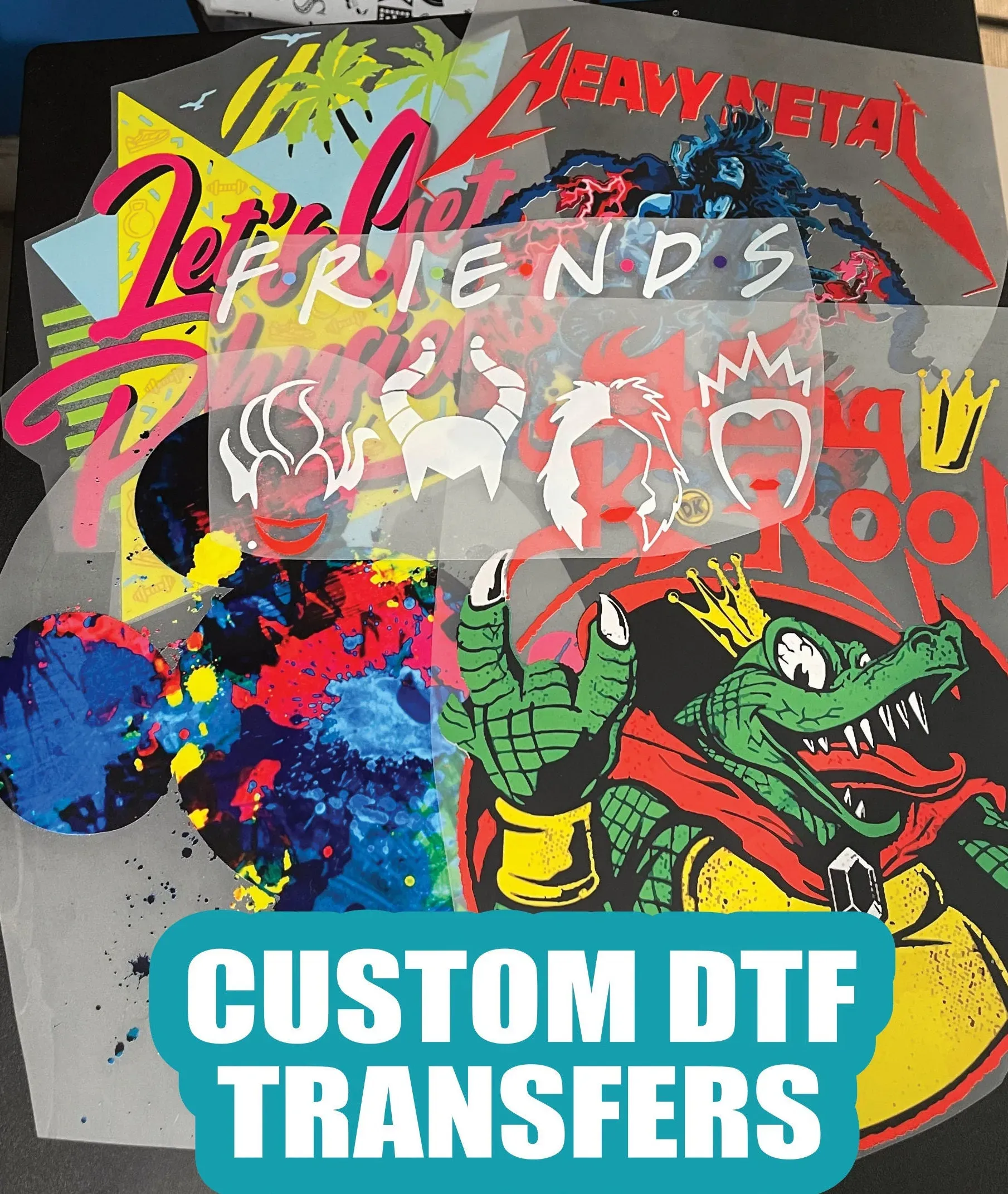

DTF transfers, or Direct-to-Film transfers, have revolutionized the custom apparel sector, introducing a new era of apparel printing technology that emphasizes quality and efficiency. This innovative printing method allows for vibrant, high-resolution designs to be applied to various fabrics, making personalized clothing more accessible than ever. As the demand for unique and sustainable fashion grows, DTF technology stands out by minimizing environmental impact through eco-friendly production processes. From small businesses experimenting with limited editions to established brands seeking durability in their products, the versatility of DTF transfers meets the needs of all. Join the trend of custom apparel that combines stunning aesthetics with sustainability, as DTF printing transforms how we wear our individuality.

Direct-to-Film printing has become a buzzword in the realm of personalized clothing, offering a fresh perspective on how designs can be transferred onto fabrics with ease and precision. This method of apparel printing stands out due to its ability to produce intricate, colorful designs that maintain their vibrancy over time. With the rising interest in eco-conscious fashion choices, many are turning to this innovative technology that not only enhances product longevity but also meets sustainability standards. Whether referred to as DTF printing or simply film transfers, this technique enables creators and businesses alike to distinguish their offerings in a competitive marketplace. As consumers increasingly seek customized fashion that reflects their style, embracing DTF technology is proving to be a wise investment.

The Rise of Eco-Friendly Apparel: Embracing DTF Transfers

In an era of heightened environmental awareness, the demand for eco-friendly apparel is surging. Custom apparel brands that adopt sustainable practices have found a dedicated customer base increasingly focused on ethical fashion. **DTF transfers** stand at the forefront of this movement by utilizing water-based inks and minimizing production waste. This modern printing technology not only reduces harmful emissions but also aligns with the principles of sustainable fashion, appealing to consumers who wish to make greener choices when shopping.

Furthermore, businesses focusing on sustainability see an opportunity to differentiate themselves in the competitive market. By transitioning to **DTF printing**, they not only contribute to reducing environmental impact but also position their brand as conscious and forward-thinking. This resonates well with today’s consumers, who prioritize purchasing from brands that share their values, leading to increased loyalty and potential growth in the eco-friendly apparel space.

Vibrant Prints That Last: The Quality of DTF Transfers

Quality is a critical factor for success in the custom apparel industry, and **DTF transfers** offer remarkable durability and vibrancy. Unlike traditional screen printing techniques that can diminish over time, DTF technology produces prints that maintain their color integrity even after numerous washes. This ensures that the customer’s investment in personalized clothing remains visually appealing for a longer duration, enhancing overall customer satisfaction.

Moreover, the ability of DTF printing to deliver intricate designs without compromising detail sets it apart from other printing methods. Brands can confidently offer products that not only meet but exceed customer expectations in terms of print quality and design versatility. This high resolution and stunning color depth open up a world of creative possibilities for custom apparel creators.

Cost-Effective Solutions for Small Businesses: DTF Printing

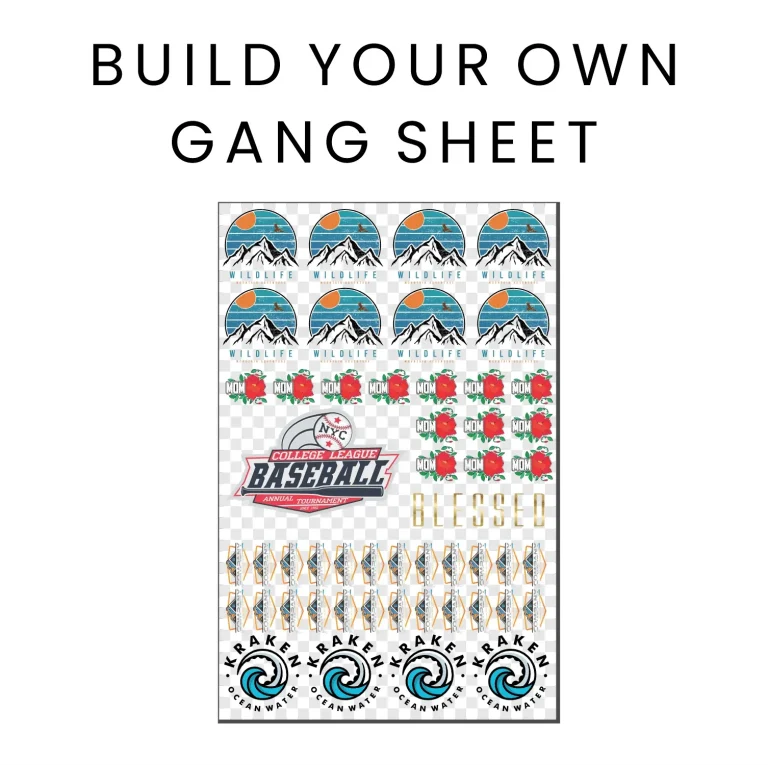

For small businesses and independent creators, keeping production costs low while maintaining quality is crucial for survival and growth. **DTF transfer technology** offers a solution that enables these entrepreneurial spirits to produce high-quality custom apparel without the financial burden associated with large production runs. Unlike traditional methods that require costly setup fees, DTF allows for smaller batch production—making it more feasible for startups to experiment with designs and styles.

This cost-effective approach not only encourages creativity but also allows brands to respond swiftly to market trends. Small businesses can test new concepts with limited editions, enabling them to gauge customer preferences before committing to larger quantities. This agility in production can lead to higher profits and strengthened brand loyalty over time.

Versatility Across Fabrics: The DTF Advantage

One of the most significant advantages of **DTF transfers** is their adaptability to a wide range of fabrics. From cotton to polyester and blends, this technology caters to diverse custom apparel needs, making it a versatile solution for businesses aiming to reach different customer demographics. This adaptability opens up various opportunities for entrepreneurs who wish to create special collections that appeal to specific audience tastes.

Moreover, the flexibility of DTF printing extends beyond just fabric types; it also encompasses various garment styles, from t-shirts to activewear, allowing brands to offer personalized clothing across multiple categories. This versatility not only enhances creativity but also places businesses in a favorable position to capitalize on niche markets within the apparel industry.

Delivering Efficiency with Quick Turnaround Times

In today’s fast-paced retail environment, quick turnaround times are essential for maintaining customer satisfaction and driving sales. **DTF transfer technology** significantly reduces the printing and fulfillment times compared to traditional methods. Businesses can respond promptly to customer orders, producing high-quality custom apparel without the waits typically associated with other printing techniques.

Additionally, this efficiency serves as a competitive edge. Brands that can promise rapid delivery of personalized clothing often foster higher customer retention and attract repeat business. With consumers increasingly seeking faster service, leveraging the speed of DTF printing can play a crucial role in a brand’s growth strategy.

The User-Friendly Nature of DTF Printing Equipment

While high-quality printing often comes with steep learning curves, **DTF printing setups** are designed to be user-friendly. This accessibility enables both industry professionals and novices to achieve stunning results without needing extensive technical knowledge. The simplicity of DTF equipment empowers new entrepreneurs to enter the custom apparel market confidently, leveling the playing field.

Moreover, as more creators embrace DTF technology, the potential for innovation and unique brand identity flourishes. With intuitive setups, individuals can experiment with their designs, paving the way for a diverse array of custom products that cater to evolving consumer preferences and trends in personalized clothing.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel?

DTF transfers, or Direct-to-Film transfers, are a printing technology that allows vibrant designs to be printed onto a film and then heat-pressed onto garments. This method ensures high-quality, long-lasting prints for custom apparel, transforming how designs are applied to clothing.

How does DTF printing contribute to sustainable fashion?

DTF printing supports sustainable fashion by utilizing water-based inks and reducing production waste. It minimizes environmental impact compared to traditional printing methods, making it an eco-friendly choice for businesses committed to sustainable practices in custom apparel.

What are the benefits of using DTF transfers for personalized clothing?

DTF transfers offer several benefits for personalized clothing, including vibrant prints, compatibility with various fabric types, and no need for weeding. This technology allows for intricate designs, making it easier for businesses to create unique, custom pieces tailored to individual customer preferences.

Why is DTF transfer technology cost-effective for small businesses?

DTF transfer technology allows small businesses to perform cost-effective small runs without the need for bulk orders. This flexibility lets entrepreneurs experiment with new designs or limited editions, significantly lowering financial risk while engaging with customer demands for custom apparel.

How does the DTF transfer process ensure high detail and resolution in prints?

The DTF transfer process utilizes advanced printing techniques that can reproduce high-resolution graphics with exceptional clarity. This capability is ideal for custom artwork and logos, ensuring that detailed designs maintain their quality and appeal, making DTF an excellent choice for custom apparel.

What innovations in DTF printing equipment are shaping the future of custom apparel?

Recent innovations such as the Insta DTF and advancements in printing solutions are enhancing precision and capability in the DTF transfer process. These technological developments signify that DTF printing is evolving, setting a new standard for efficiency and quality in custom apparel production.

| Key Point | Description |

|---|---|

| Eco-Friendly Production | Minimizes waste, uses water-based inks, and aligns with sustainability. |

| Vibrant and Durable Prints | Produces bright, high-quality prints that last through numerous washes. |

| Cost-Effective for Small Runs | Enables small production runs without hefty upfront costs, ideal for independent creators. |

| Versatility Across Fabrics | Works on various fabrics, accommodating different custom apparel needs. |

| Quick Turnaround Times | Faster printing and delivery improves customer satisfaction and brand reputation. |

| User-Friendly Setup | Accessible technology for both professionals and beginners in custom apparel. |

| High Detail and Resolution | Exceptional clarity in intricate designs and graphics, pleasing discerning customers. |

| No Weeding Required | Eliminates laborious weeding processes, optimizing production time. |

| High-Quality Adhesives | Enhances print longevity and provides professional-quality results. |

| Innovative Equipment Development | Ongoing advancements in technology improve precision and capabilities in DTF printing. |

Summary

DTF Transfers are redefining the landscape of custom apparel through their efficiency, sustainability, and impressive print quality. These innovations not only meet the growing consumer demand for environmentally friendly solutions but also allow businesses to stay competitive by offering vibrant, durable designs. With the flexibility and accessibility of DTF technology, small and large businesses alike can create unique apparel without the burden of high costs or lengthy production times. As the industry continues to evolve, DTF transfers are set to remain at the forefront, ensuring that the future of custom apparel is vibrant, sustainable, and accessible for all.