In the vibrant realm of custom printing, **DIY DTF supplies** are game-changers, empowering creative enthusiasts to produce extraordinary products from the comfort of their own homes. DTF, or Direct-to-Film printing, stands out for its ability to render intricate and colorful designs on a myriad of materials with exceptional clarity. This innovative printing technique has seen a surge in popularity, especially with advanced offerings like the LOKLiK iPrinter DTF-A3-XP600, which makes DIY DTF setups not only attainable but also enjoyable for everyone. Understanding how to harness these supplies is crucial for anyone looking to venture into this exciting field. In this article, we will explore the essentials of establishing your own custom printing setup, ensuring you’re well-equipped to embark on your DTF journey and create stunning prints.

When delving into the fascinating world of direct-to-film crafting, one comes across a plethora of tools and materials designed to enhance the custom printing experience. As the popularity of techniques like DTF printing rises, so does the accessibility of necessary components, including films, printers, and adhesives. Individuals seeking to personalize their designs can turn to a custom printing setup that allows them to bring their unique visions to life. This alternative approach not only invites experimentation with various mediums but also fosters a community of creators eager to share their successes. Embracing these technologies, particularly products like the LOKLiK iPrinter, opens doors to endless possibilities in apparel design and more.

Essential Equipment for DTF Printing

A successful DIY DTF printing setup begins with the right equipment. At the forefront of this operation is the DTF printer. The LOKLiK iPrinter DTF-A3-XP600, for instance, is engineered specifically for optimal DTF functionality, ensuring that users can achieve vibrant prints consistently. This printer supports a variety of materials, enabling you to explore different fabric types for your projects, making it a versatile choice for both beginners and experienced designers.

Besides the printer, a high-quality heat press is crucial for transferring your designs effectively. The heat press must allow for precise control over temperature and pressure, catering to the diverse requirements of the fabrics you’re printing on. By investing in reliable equipment, you’ll create a sturdy foundation for your custom printing setup, allowing your creativity to flow without technical interruptions.

Frequently Asked Questions

What are some essential DIY DTF supplies needed to start DTF printing?

To start your DTF printing journey, you’ll need essential supplies such as a DTF printer, specifically the LOKLiK iPrinter DTF-A3-XP600, high-quality DTF film, DTF inks compatible with your printer, a heat press for transferring designs, and adhesive powder to ensure designs stick to the fabric.

How does DTF printing differ from traditional printing methods?

DTF printing, or Direct-to-Film printing, uses a printed film that transfers vibrant designs onto fabric through heat and pressure. Unlike traditional methods, DTF allows for intricate designs and high-quality prints on various materials, making it ideal for custom apparel and merchandise.

What should I consider when choosing DTF film for my custom printing setup?

When selecting DTF film for your DIY custom printing setup, opt for high-quality film that provides excellent ink adhesion and vibrant color output. It’s essential to ensure compatibility with your DTF printer to achieve the best results in your printing projects.

How do I achieve the best results with my LOKLiK iPrinter DTF-A3-XP600?

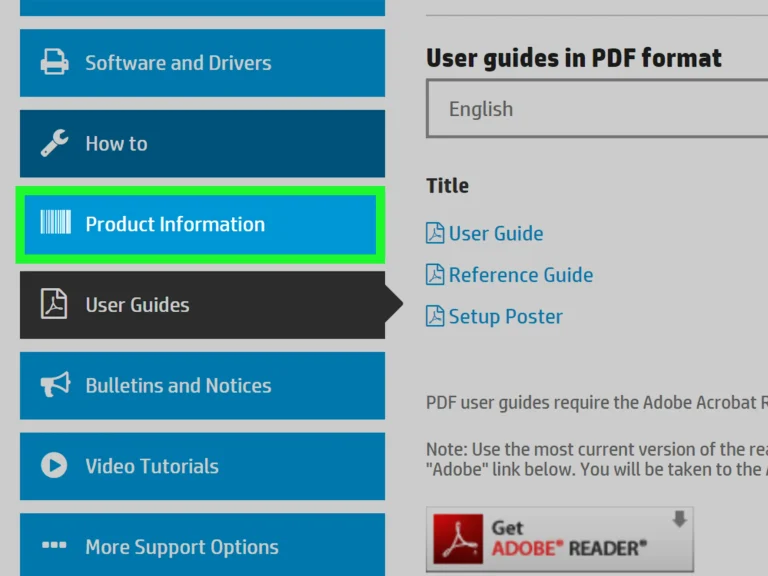

To achieve the best results with your LOKLiK iPrinter DTF-A3-XP600, ensure you’re using compatible DTF inks and high-quality DTF film. Additionally, calibrate your printer settings according to the manufacturer’s guidelines for optimal print quality.

What is the purpose of adhesive powder in DTF printing?

Adhesive powder is crucial in DTF printing as it ensures that the printed design adheres well to the fabric. After printing on the DTF film, this powder is applied before curing with heat, bonding the design securely during the transfer process.

Can I create custom designs for various fabrics using DIY DTF supplies?

Yes, with DIY DTF supplies, you can create custom designs for a wide range of fabrics, including t-shirts, hoodies, and tote bags. The versatility of DTF printing enables you to print on various materials while maintaining vibrant colors and intricate details.

| Key Point | Description |

|---|---|

| DIY DTF Supplies | Supplies for creating custom prints using Direct-to-Film printing. |

| DTF Printing | A method that transfers prints from film to fabric, suitable for intricate designs. |

| LOKLiK iPrinter DTF-A3-XP600 | A recommended printer specifically designed for DTF printing. |

| DTF Film | Specialty film for transferring images onto fabric. |

| DTF Inks | Inks that are compatible with DTF printing for vibrant results. |

| Heat Press | Essential equipment to transfer designs onto fabric. |

| Adhesive Powder | Used to ensure prints adhere to fabric during heat transfer. |

| Workstation Setup | A dedicated, organized space is necessary for efficient printing. |

Summary

DIY DTF supplies enable creatives and entrepreneurs to delve into the exciting realm of custom printing. This innovative method, which allows for vibrant and durable designs on various fabrics, is transforming how individuals approach apparel and merchandise creation. By using a combination of specialized equipment like the LOKLiK iPrinter DTF-A3-XP600, high-quality DTF film, and appropriate inks, anyone can start a successful DIY DTF printing venture from the comfort of their home. Furthermore, establishing an organized workspace and understanding the printing process are key to ensuring quality results. Embrace the customization possibilities that DIY DTF supplies offer and join a thriving community eager to share tips and creativity.