To maximize printing quality, attention to detail and the right materials are essential for success in Direct-to-Film (DTF) printing. This innovative technique has gained traction among businesses and artists wanting to deliver high-quality prints that capture attention. With the best DTF printers, premium DTF transfer film, and high-quality inks, you can ensure vivid colors and durability in your prints. In this article, we will delve into the must-have DTF printing supplies that will elevate your printing experience, helping you stand out in a competitive market. By strategically selecting your equipment and materials, you can maximize printing quality and achieve stunning results.

When discussing the art of maximized print excellence, it’s hard to overlook the significance of direct-to-film technology. As a rapidly evolving method, DTF printing enables creative professionals to produce striking prints that resonate with potential customers. By utilizing top-notch direct-to-film supplies—from printers designed for high performance to the finest transfer films and inks—one can achieve exceptional visual results. In this exploration, we will highlight essential resources and innovations that are redefining print quality standards, ensuring your work not only meets but exceeds expectations. Embracing these advancements allows both newcomers and veterans in the industry to elevate their craft and maximize printing quality effectively.

Maximize Printing Quality with Top DTF Supplies

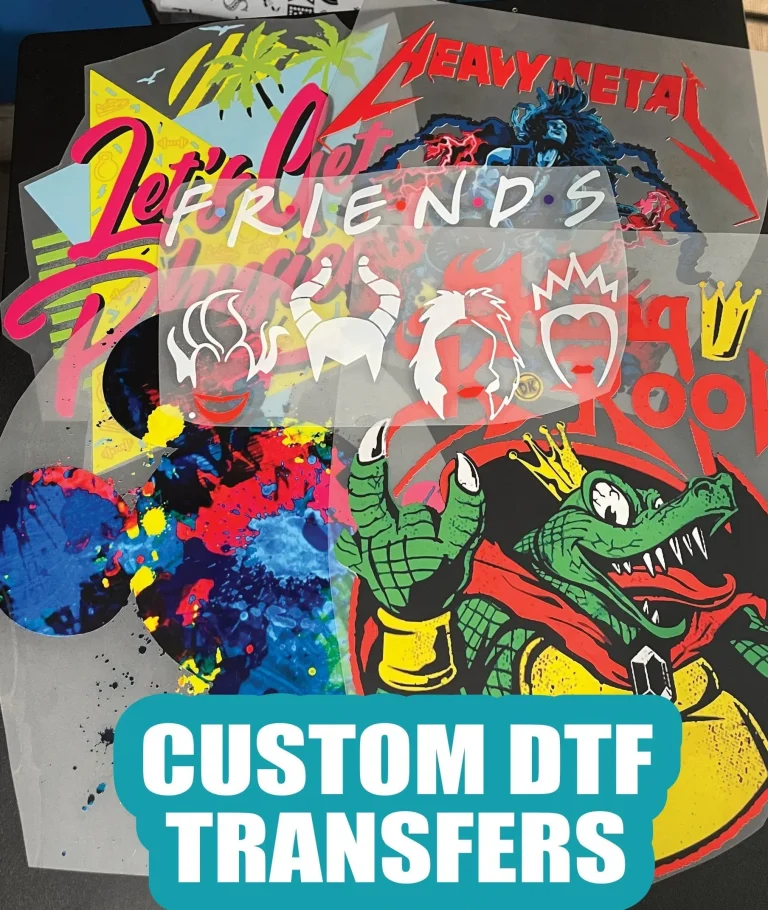

To maximize printing quality in Direct-to-Film (DTF) printing, the selection of the right supplies cannot be overstated. High-quality inks and transfer films play a critical role in ensuring that your prints are not only vivid but durable as well. The choice of **DTF printing supplies** should be guided by compatibility with your printer and the desired output. For instance, investing in premium DTF inks can lead to more vibrant colors and sharper details, making all the difference in the final product.

Moreover, choosing suitable **DTF transfer films** is equally important, as they determine how well the design adheres to various fabrics. Brands that are recognized for producing high-quality films can significantly enhance your print’s longevity and washability. By ensuring that all supplies are of top-grade quality, you can genuinely maximize your printing quality, elevating your competitive edge in the market.

Choosing the Best DTF Printers

Finding the best DTF printers is essential for achieving exemplary print results. Modern printers, such as the **LOKLiK iPrinter DTF-A3-XP600**, are engineered to deliver superior output and are equipped with advanced features that streamline the printing process. These printers offer high resolution and speed, catering to both newcomers and seasoned professionals alike. When selecting a printer, consider its compatibility with various **DTF inks** and films for optimal results.

Additionally, the effectiveness of the printer’s printhead, like the industry-leading XP600, should not be overlooked. High-performance printheads are crucial for creating fine details and vibrant color gradients. By investing in the best DTF printers available, you ensure that your printing process is efficient and results in the highest quality finished products.

The Role of High-Quality Inks in DTF Printing

High-quality inks are a fundamental component of successful DTF printing. The choice of inks can significantly influence the color vibrancy and durability of your prints. Inks that are specifically designed for DTF printing provide superior adhesion to transfer films, leading to products that last longer and maintain their colors. When selecting inks, ensure they are compatible with your specific DTF printer to achieve the best results.

Moreover, the formulation of these inks can affect how they react under different printing conditions. For instance, specially formulated inks can enhance the depth of color and improve overall print quality, making them an investment worth considering. In short, using high-quality inks is essential for maximizing printing quality and ensuring that your designs stand out.

Understanding DTF Transfer Film Choices

Choosing the right DTF transfer film is crucial for achieving optimal printing quality. The transfer film acts as a medium through which the printed design is transferred onto the fabric, so its quality directly impacts the final product. Films designed for high-resolution applications can significantly improve the clarity and detail of your prints, ensuring that intricate designs translate well onto the fabric.

Additionally, not all transfer films are created equal; some are specially formulated to work better with certain inks and printers. For example, using a transfer film that perfectly aligns with your high-quality inks can result in better adhesion and durability, leading to prints that withstand repeated washes and wear. Understanding the nuances of different **DTF transfer film** options will help you make informed choices that enhance your final output.

Innovations in DTF Technology and Their Impact

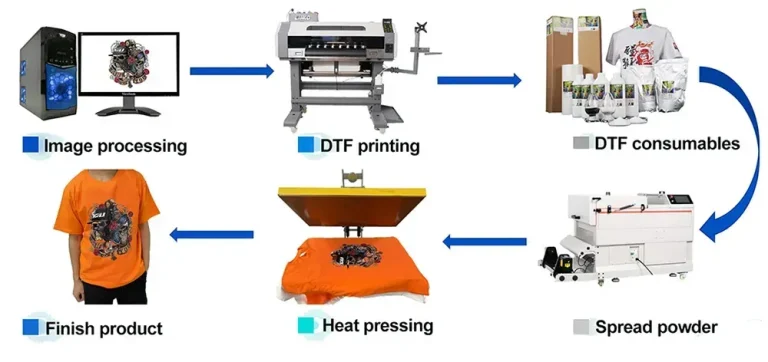

The Direct-to-Film (DTF) printing industry has seen remarkable innovations that significantly enhance printing quality. For example, recent advancements in UV DTF technology introduce new possibilities by allowing prints to adhere to a wider range of surfaces using just ink and varnish. These pioneering developments expand the creative potential for artists and businesses, paving the way for unique applications and products.

Moreover, companies like EazyDTF and Snuggle are investing heavily in their DTF technology capabilities. This not only leads to an increased capacity for producing high-quality transfers but also ensures faster turnaround times for businesses. Keeping abreast of these innovations and incorporating them into your printing process can help you maintain an edge in the competitive landscape of DTF printing.

Tips for Maintaining DTF Printing Quality

To maintain the maximized printing quality achieved with DTF supplies, it’s essential to implement routine printer maintenance. Regular cleaning of print heads and ensuring optimal ink flow can help prevent clogging and other issues that commonly affect print quality. Additionally, recalibrating your printer settings periodically to match your supplies can help you sustain high standards in your output.

Another useful tip is to engage in trial and error with various brands of **DTF inks** and transfer films. Each printer behaves differently, and experimenting helps you uncover the perfect combination that enhances quality for your specific setup. Combining frequent maintenance with smart experimentation can greatly enhance your overall printing outcomes.

Frequently Asked Questions

How can I maximize printing quality with DTF printing supplies?

Maximizing printing quality in DTF printing begins with using high-quality DTF printing supplies, including the best DTF printers and compatible inks. Make sure to select DTF transfer films specifically designed for your printer to ensure excellent adhesion and vibrant colors. Regular equipment maintenance and testing various supplies can also enhance your print quality.

What are the best DTF printers to maximize printing quality?

The best DTF printers for maximizing printing quality are those known for their reliability and advanced technology, such as the LOKLiK iPrinter DTF-A3-XP600. This printer features an XP600 printhead, ensuring consistent, high-quality output. When choosing a printer, prioritize durability and compatibility with high-quality inks and transfer films.

Why is it important to use high-quality inks in Direct-to-Film printing?

Using high-quality inks in Direct-to-Film (DTF) printing is crucial to achieving vivid colors and sharp details in your designs. High-quality inks ensure proper adhesion to the DTF transfer film and fabric, leading to longer-lasting and more vibrant prints. Always choose inks compatible with your DTF printer to maximize printing quality.

How does DTF transfer film affect print quality in DTF printing?

DTF transfer film significantly impacts print quality as it determines how well the design adheres to the fabric. Selecting a DTF transfer film tailored for your printer is essential; the right film enhances color retention and wash durability, thereby maximizing printing quality for your projects.

What is hot melt powder and how does it enhance DTF printing quality?

Hot melt powder is a crucial component in the DTF printing process that enhances the bond between the print and the fabric, leading to improved durability and washability of prints. Choosing the right hot melt powder that complements your high-quality inks and transfer films is essential to maximizing printing quality.

What recent developments in DTF supplies can help maximize printing quality?

Recent developments in DTF supplies include advancements in large format printers and new services like Snuggle’s trade service for DTF transfers, which can produce high-quality transfers efficiently. These innovations improve production capabilities and printing quality, allowing businesses to keep pace with market demands while ensuring vibrant print outcomes.

| Key Component | Description | ||

|---|---|---|---|

| High-Quality DTF Printers | Crucial for producing vibrant prints; such as the LOKLiK iPrinter DTF-A3-XP600 with advanced features and bundled supplies. | Check for printhead quality and durability for consistent results. | |

| Quality Inks and Transfer Films | Using compatible high-quality inks ensures color vibrancy and sharp details, while specially designed transfer films enhance adhesion. | Select according to printer type for optimal performance. | |

| Hot Melt Powder | Essential for bonding prints to different surfaces, ensuring durability and washability. | Follow manufacturer recommendations for best results. | |

| Recent Developments | Services like Snuggle’s trade service and EazyDTF’s large format technology enhance quality and efficiency. | Mimaki’s UV DTF technology allows versatility by adhering to various surfaces. | |

Summary

To maximize printing quality, selecting the right DTF supplies is essential for achieving high standards in Direct-to-Film printing. This process begins with investing in high-quality printers, inks, and transfer films, all of which contribute significantly to the overall output quality. As the DTF technology landscape evolves, staying informed about the latest innovations ensures that you can adapt your printing process for optimal results. Being proactive in your approach not only elevates your prints but also positions you to meet the demands of a competitive market effectively.