In the dynamic world of the printing industry, **UV DTF Gangheet** emerges as a revolutionary technique that is reshaping the way designs are produced and distributed, especially in custom apparel. This cutting-edge printing technology combines the benefits of DTF (Direct-to-Film) with UV printing processes, offering businesses unique advantages in quality and versatility. By optimizing material usage and minimizing costs through efficient bulk printing, UV DTF Gangheet stands out as an essential tool for modern enterprises. With its rapid production capabilities and ability to create vibrant, durable designs, this method perfectly caters to the growing demand for personalized products. Join us as we delve deeper into the workings and benefits of UV DTF Gangheet, a pivotal player in contemporary printing solutions.

The landscape of custom printing is evolving, and terms like **Direct-to-Film printing** and **UV printing** are becoming synonymous with innovation in this field. The Gangheet process, which allows for the production of multiple designs on a single film sheet, exemplifies the efficiency that new technologies bring to the table. Businesses looking to enhance their printing capabilities can leverage the advantages of this advanced printing technology, enabling them to offer a diverse array of custom apparel and promotional items. By incorporating UV DTF techniques, companies can meet the growing consumer demand for unique products while also optimizing their production processes. This transition highlights the exciting developments occurring in the printing industry, positioning businesses for success in an increasingly competitive market.

The Evolution of DTF Printing Technology

DTF printing, which stands for Direct-to-Film printing, has gained substantial traction in the printing industry due to its innovative approach and impressive capabilities. Traditionally, printers relied heavily on methods like screen printing that required complex setups and significant time investments. DTF technology has streamlined this process by enabling high-quality designs to be transferred onto films, which are then easily applied to various fabrics. Businesses quickly realized the benefits of this method, as it allows for vivid colors and intricate designs that were often challenging to achieve with older systems.

Moreover, the efficiency of DTF printing makes it highly attractive for custom apparel production. Companies can create small runs of unique designs without incurring the high costs typically associated with bulk printing. This shift in capability empowers brands to cater to niche markets, allowing for more personalized offerings that resonate with consumers. As the DTF printing technique evolves, it continually sets new industry standards, prompting further exploration into how it can be enhanced and optimized for different applications.

UV DTF Gangheet: A Game Changer in Customization

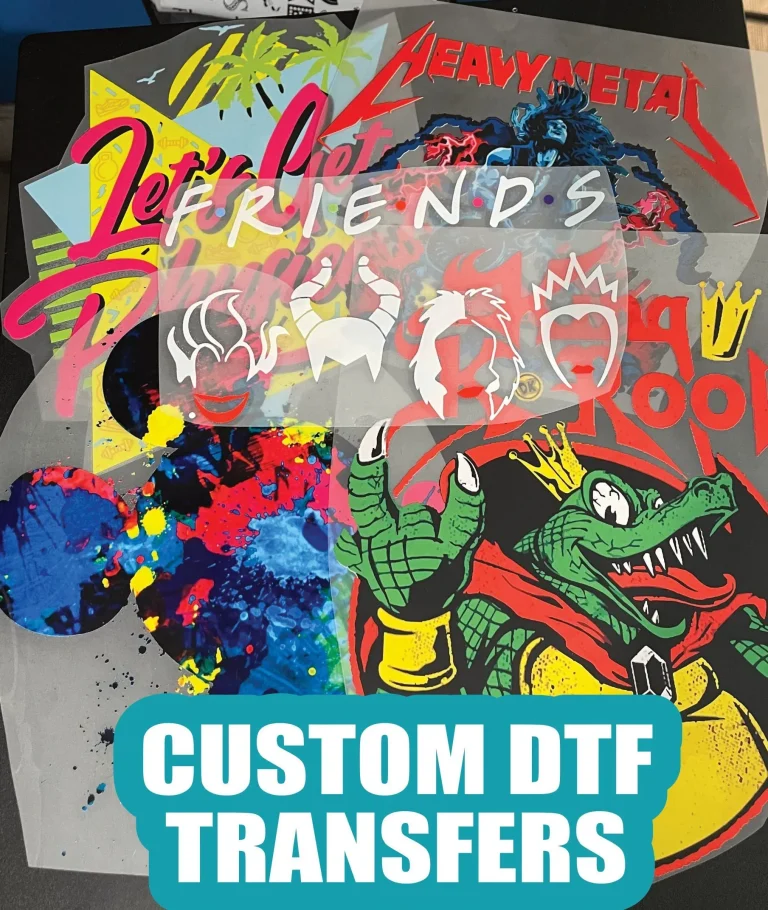

One of the standout features of UV DTF Gangheet is its ability to optimize material usage by printing multiple designs on one film sheet. This substantial advancement not only enhances cost-effective production but also aligns perfectly with the growing consumer trend towards personalized items. With the integration of UV printing technologies, Gangheet combines both versatility and innovation, allowing businesses to offer diverse options within their custom apparel lines. This shift has an immediate impact on how companies market and sell their products, as they can now provide unique designs without escalating costs.

Furthermore, UV DTF Gangheet is at the forefront of sustainable printing practices. By minimizing waste and maximizing design impact, businesses can address consumer concerns regarding environmental responsibility while still delivering quality products. This method supports a circular economy, where resources are utilized efficiently without compromising on quality. As brands become more conscious of their ecological footprint, the adoption of UV DTF Gangheet will become more prevalent, reinforcing its transformative role in the current printing landscape.

Innovations in Substrates with UV DTF Technology

The versatility of UV DTF printing goes beyond traditional textiles, expanding into various materials such as wood, metal, and glass. This capability opens a world of possibilities for businesses looking to diversify their product offerings and tap into new markets. The integration of UV technology allows for vibrant designs to be created on numerous surfaces, which is essential for companies aiming to stand out in a competitive environment. Whether it’s customized gifts or promotional items, the innovation behind UV DTF presents endless opportunities.

This adaptability underscores a significant trend in consumer behavior—there is a growing demand for personalized products that reflect individual tastes and preferences. Businesses leveraging UV DTF technology can meet this demand by providing unique, multi-surface item ranges that cater to a wide array of consumers. As the market continues to evolve, those who harness the power of UV DTF will likely find themselves at a distinct advantage, capturing consumer interest through innovative and personalized offerings.

Market Demand for UV DTF Printing Solutions

The market for UV DTF printing solutions is experiencing substantial growth, driven by the unique advantages this technology offers. Current trends indicate a shift towards on-demand printing systems, where businesses are seeking ways to produce high-quality prints rapidly while maintaining cost efficiency. In this context, UV DTF products allow for quick turnarounds and high quality, attracting a robust customer base that thrives on immediacy and personalization. As companies implement these solutions, they not only enhance their operational distribution but also boost customer satisfaction.

Furthermore, as brands increasingly prioritize customization in their offerings, the demand for UV DTF technology is expected to surge. Businesses that adopt this innovative printing method will be better positioned to cater to customers who desire unique and creative designs. The capacity to deliver personalized products with minimal lead time demonstrates a significant competitive edge in the saturated marketplace, pushing the boundaries of what’s possible in printing technology.

Sustainability Practices with DTF Technology

Sustainability is a crucial consideration for the modern printing industry, and DTF technology presents many advantages in this area. Its efficient use of materials means less waste, as multiple designs can be printed simultaneously on a single film. This not only conserves resources but also supports businesses in adopting greener practices, which are increasingly demanded by environmentally conscious consumers. As sustainable practices become a standard expectation, the introduction of DTF printing aligns well with broader goals of reducing environmental impact.

Moreover, the low ink consumption associated with DTF printing methods underscores the potential for substantial cost savings alongside environmental benefits. By reducing the amount of ink used in production, companies can minimize their carbon footprint while maintaining high-quality outputs. The combination of economic and ecological advantages positions DTF printing—especially UV DTF Gangheet—as a forward-thinking solution for businesses striving to align with sustainable goals while also addressing customer preferences for responsible production.

The Future of UV DTF Printing Technology

Looking ahead, the future of UV DTF printing technology is incredibly promising, with continued innovations poised to shape its trajectory in the printing industry. As manufacturers invest in cutting-edge equipment and techniques, the speed and quality of UV DTF outputs are set to improve significantly. This progression will not only enhance the production capabilities of businesses but also push the boundaries of creativity in custom apparel and product manufacturing.

Additionally, as consumer trends lean more towards personalization and unique design solutions, UV DTF printing is well-positioned to meet these demands. The expansion of DTF technology is likely to lead to even more substrate options, enabling businesses to explore new product lines. Companies that embrace UV DTF will not only keep pace with evolving industry standards but also pioneer innovative approaches that redefine how products are designed, customized, and produced in the future.

Frequently Asked Questions

What is UV DTF Gangheet and its role in modern printing technology?

UV DTF Gangheet refers to a cutting-edge printing method that allows multiple designs to be printed on a single film sheet using UV DTF technology. This process optimizes material usage and reduces overall costs, making it a game changer in the custom apparel market and printing industry.

How does UV DTF Gangheet improve the cost-effectiveness of DTF printing?

By utilizing the Gangheet process, UV DTF printing reduces the number of prints needed for bulk orders, thereby minimizing ink usage and material waste. This leads to significant cost savings for businesses in the printing industry, making DTF an attractive option for custom apparel production.

What advantages does UV DTF Gangheet offer over traditional printing methods?

UV DTF Gangheet provides enhanced versatility, allowing for vibrant designs on various substrates beyond textiles, such as wood and metal. Its fast production times and cost-efficient printing capabilities make it preferable over traditional methods in the rapidly evolving printing market.

Can UV DTF Gangheet be used for personalized custom apparel?

Yes, UV DTF Gangheet excels in creating personalized custom apparel due to its flexibility in design and ability to produce high-quality prints rapidly. This makes it an ideal choice for businesses looking to meet the diverse demands of consumers seeking unique clothing items.

What recent developments have impacted UV DTF Gangheet in the printing industry?

Recent advancements, such as the expansion of companies like EazyDTF deploying large-format DTF printers, have significantly increased production capacity. These innovations make it possible to fulfill growing customer demands for custom prints in shorter turnaround times.

How does UV DTF Gangheet align with market growth trends in the printing industry?

As consumer preferences shift towards customization and quick delivery, UV DTF Gangheet is ideally positioned to cater to these trends. Its ability to produce diverse, high-quality prints quickly places it at the forefront of the robust growth seen in the printing industry.

| Key Point | Description |

|---|---|

| Introduction to UV DTF Gangheet | A game changer in the printing industry, particularly for custom apparel. |

| Understanding DTF Printing | Technique where designs are printed on film and transferred to fabric using heat and pressure. |

| Benefits of DTF Printing | Offers versatility, cost-effectiveness, and faster production times. |

| Significance of Gangheet | Allows printing multiple designs on a single sheet, optimizing material use and reducing costs. |

| Recent Developments | Companies like EazyDTF are expanding operations to meet demand with cutting-edge technology. |

| Innovations in UV DTF Technology | Expands printing capabilities beyond textiles to substrates like wood, metal, and glass. |

| Market Growth | The printing industry is growing, driven by advancements in DTF technology. |

| Versatile Nature of DTF Printing | Used by businesses from startups to large corporations to enhance product offerings. |

Summary

UV DTF Gangheet is revolutionizing the printing industry by streamlining processes and maximizing efficiency. This innovative printing technology is not only cost-effective but also opens up new avenues for customization in the market. As brands increasingly seek unique and personalized products, UV DTF Gangheet allows them to meet these demands with high-quality, versatile printing solutions. Furthermore, with recent advancements and a growing appetite for diverse and innovative prints, UV DTF Gangheet will undoubtedly play a pivotal role in shaping the future of the printing landscape.