DTF Supplies play a vital role in revolutionizing the world of custom apparel and promotional printing. As businesses and creators seek high-quality outputs, Direct to Film (DTF) printing has become the preferred method for achieving vibrant and detailed designs. Utilizing top-notch DTF printers and transfer powders, this printing technique allows for extraordinary graphics that resist fading and wear over time. Ensuring you have the necessary DTF films and inks can lead to impressive results that cater to a variety of fabric types. In this guide, we will explore essential DTF supplies to help you maximize your print quality and deliver professional-grade finishes in all your projects.

When it comes to enhancing print quality for custom garments, understanding the essentials of Direct to Film technology is crucial. This innovative printing method, known for its exceptional color accuracy and design detail, allows for a seamless transfer of intricate images onto various textiles. By incorporating high-performance printing equipment and quality transfer materials, enthusiasts can unveil striking visuals that stand the test of time. Familiarizing yourself with the key items like DTF films, high-quality inks, and powder applies will elevate your printing capabilities significantly. Whether you’re a seasoned pro or new to this printing technique, mastering the right supplies is the first step toward achieving stunning results.

Understanding the DTF Printing Process

Direct to Film (DTF) printing has transformed the landscape of garment printing by providing a method that excels in detail and color quality. This process employs a film medium, allowing for intricate designs to be printed before transferring them onto fabric. Unlike traditional methods, DTF printing captures vibrant colors and crisp details that can withstand the rigors of washing and wearing, making it ideal for custom apparel and promotional items.

To fully leverage the advantages of DTF printing, understanding how the process works is vital. The film acts as a transfer medium that carries the ink to the fabric, ensuring that the design retains its vibrancy. It’s important to familiarize yourself with the various components of DTF printing, including the inks, films, and transfer powders, to maximize the efficiency and output of your printing experience.

Key Features of High-Quality DTF Printers

Selecting the right DTF printer is crucial for achieving high-quality outputs. High-quality DTF printers are designed with advanced technology, such as improved printhead systems and optimized ink pathways, allowing for better resolution and consistency. Among the popular options, models featuring the XP600 printhead technology stand out, enabling users to produce detailed graphics with superb color accuracy.

Moreover, top-tier DTF printers offer compatibility with various ink types, providing users with flexibility in color choices and designs. Investing in a high-quality printer typically translates to enhanced performance, reliability, and longevity, all of which are pivotal for businesses aiming to deliver professional-grade products that meet customer expectations.

Essential DTF Films for Optimal Results

Choosing the right DTF film plays a significant role in the quality of prints you can achieve. The film acts as a canvas for your designs before they are transferred to fabric, so it’s essential to select the right thickness and quality. High-quality DTF films support better ink adherence, enabling vibrant colors and fine details to shine through after the transfer process.

Additionally, films that provide durability and resistance to wear and tear are vital for ensuring that prints maintain their integrity over time. When looking for DTF films, consider options that have been extensively tested and approved by the printer manufacturer to ensure compatibility, which will ultimately contribute to achieving the best possible print results.

The Importance of DTF Transfer Powders

In the DTF printing process, transfer powders are critical for ensuring that your designs properly adhere to the fabric. These powders assist in creating a bond during the heat transfer process, which is essential for a durable finish. Choosing the right transfer powder can significantly impact the smoothness of the transfer, with high-quality powders flowing easily and avoiding clumping.

Moreover, the right transfer powders contribute to the overall finish and professionalism of your prints. Help your designs stand out by opting for powders that not only adhere well but also enhance the texture and quality of the print. Proper application and selection of these powders can mean the difference between a satisfactory print and a truly outstanding one.

Maximizing Print Quality with Maintenance Tips

To achieve consistent high-quality outputs in DTF printing, maintaining your printer is of utmost importance. Regular maintenance, including cleaning the print heads and ensuring proper ink flow, directly influences the color accuracy and efficiency of your printing process. A well-maintained printer not only produces better prints but also extends the lifespan of the device.

In addition to routine maintenance, conducting test prints before full production runs can help identify potential issues early. This practice allows you to make necessary adjustments to temperature, pressure, or ink usage, ensuring that your final prints meet your standards for quality and professionalism.

Experimenting with DTF Printing Techniques and Materials

Experimentation is essential when it comes to mastering DTF printing. Each project may present unique challenges that can be addressed through various techniques and materials. Trying different types of fabrics, designs, and printing settings can lead to discovering the optimal combination for achieving stunning results.

It’s also beneficial to keep abreast of the latest trends and advancements in DTF supplies, including new inks and films that may enhance your printing capabilities. By continually testing and refining your approach, you can evolve your skill set and ensure that your prints are not only high-quality but also distinct from the competition.

Frequently Asked Questions

What are the key DTF supplies I need for high-quality DTF printing?

To achieve high-quality DTF printing, you will need essential DTF supplies including a reliable DTF printer, high-quality DTF films, premium inks, effective DTF transfer powders, and a dependable heat press machine. Each item plays a vital role in ensuring vibrant colors and durable prints.

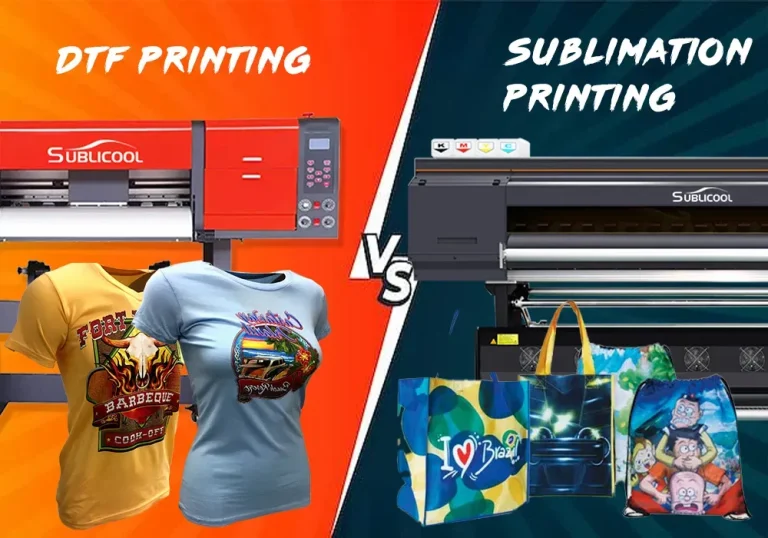

How does DTF printing differ from traditional printing methods?

DTF printing differs from traditional printing methods by utilizing a film for printing, which is then heat-transferred onto the fabric. This allows for superior color vibrancy, detail retention, and durability in designs, making it ideal for custom apparel and promotional items.

Why is it important to use high-quality DTF films?

Using high-quality DTF films is crucial for enhancing your print quality. Quality films enable better ink adherence, vibrant colors, and fine details, ensuring that your designs withstand washing and wear while maintaining their appearance.

What role do DTF transfer powders play in the printing process?

DTF transfer powders are essential because they adhere the prints to the fabric during heat pressing. Choosing powder that flows easily and applies without clumping is important for achieving smooth transfers and professional-looking results.

How can I enhance print quality with my DTF printing supplies?

To enhance print quality, ensure regular maintenance of your DTF printer, conduct test prints on various fabrics, and use compatible DTF supplies. Additionally, focus on quality control to catch any imperfections before final transfers.

What should I consider when choosing a DTF printer?

When selecting a DTF printer, consider its resolution capabilities, compatibility with various inks, user-friendly features, and maintenance requirements. The LOKLiK iPrinter DTF, for example, is renowned for its excellent print quality and technology.

| Key Points | Details |

|---|---|

| DTF Printing Benefits | Superior color vibrancy and detail retention. |

| DTF Printer | LOKLiK iPrinter DTF offers advanced printhead technology for high-resolution output. |

| DTF Film | Choose high-quality films for rich colors and durability. |

| Inks | Use high-quality CMYK and white inks for better graphics. |

| Transfer Powders | Essential for smooth adherence during heat press. |

| Heat Press Machine | Consistent temperature and pressure are vital for transfers. |

| Maintenance and Testing | Regular printer maintenance and test prints boost quality. |

| Material Compatibility | Ensure supplies are compatible with various fabric types. |

| Quality Control | Check prints for imperfections before final transfers. |

Summary

DTF Supplies play a crucial role in achieving high-quality prints, particularly for custom apparel and promotional items. By using the right DTF printer and complementary supplies like quality films, inks, and heat press machines, businesses can significantly improve their printing results. DTF printing stands apart due to its superior color vibrancy and durability, allowing creators to produce intricate designs that withstand washing and wear. Leveraging best practices such as regular maintenance and material compatibility ensures professional outcomes in every print run. Entrepreneurs and artists can, therefore, maximize their potential by investing in high-quality DTF Supplies.