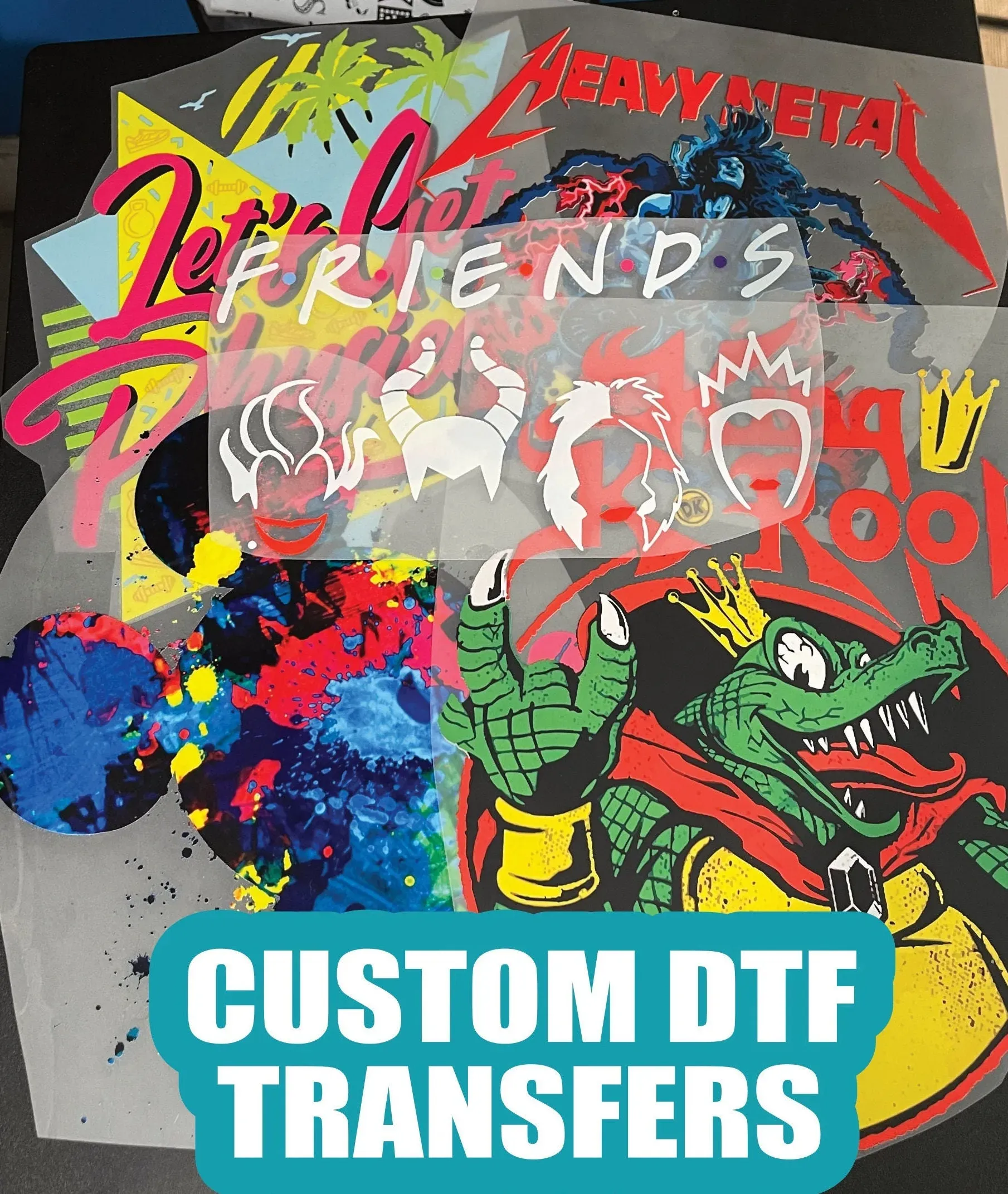

DTF Transfers have emerged as a revolutionary force in the world of textile printing, uniquely combining efficiency with exceptional quality. This innovative method, known as Direct-to-Film printing, allows for the seamless application of designs onto various fabric types, making it a go-to choice for customized textile solutions. With the remarkable DTF printing advantages, including vibrant color reproduction and durability, it caters to the needs of both entrepreneurs and hobbyists alike. As the latest printing technology continues to gain traction, it promises to redefine industry standards and meet the surging demand for tailored prints. In this blog, we delve into the capabilities of DTF Transfers and explore why they are set to dominate the textile printing landscape in the years to come.

Revolutionizing modern endorsement in fabric printing, Direct-to-Film (DTF) technology encompasses a unique approach that leverages advanced printing techniques to create customizable solutions for fabric designs. Often regarded as the future of textile imprinting, this method facilitates the application of intricate graphics onto diverse textiles with extraordinary clarity and resilience. As businesses and creators increasingly turn to custom textile solutions, the advantages of DTF, such as rapid production times and varied application possibilities, become even more apparent. Utilizing cutting-edge technology, this innovative printing system showcases the potential to transform not just garments but a broader range of creative projects. This overview highlights the significance of DTF as it carves its niche in the ever-evolving textile printing sector.

Understanding the Mechanism Behind DTF Transfers

Direct-to-Film (DTF) printing technology represents a significant leap in the realm of textile printing. Unlike traditional methods, DTF printing utilizes a specialized film to transfer designs onto fabrics. This process involves printing ink onto a PET film, which is then coated with an adhesive and subsequently heat-pressed onto the textile. The result is a durable, vivid print that can withstand multiple washes while maintaining its quality. This innovation transforms how designs are transferred, offering a level of detail and versatility that traditional screen printing struggles to match.

One of the central advantages of DTF transfers is their ability to work effectively on a diverse range of materials, from cotton to polyester blends. This versatility is further enhanced by the capability to print intricate designs and gradients without losing fidelity, making DTF a preferred choice for custom textile solutions. As the technology matures, we can expect to see advances that will push the boundaries of what can be achieved with textile printing, catering to both bulk orders and individual customizations.

Key Advantages of DTF Printing

DTF printing offers numerous advantages that make it an appealing option for businesses and consumers alike. First and foremost, the quality of prints produced through this method is exceptional, characterized by vibrant colors and intricate detail. The technology uses high-quality inks that bond effectively with different fabrics, producing a soft feel that doesn’t compromise the garment’s comfort. This quality ensures that printed products not only stand out visually but also stand the test of time, appealing to customers looking for durability.

Another significant advantage is the rapid turnaround that DTF technology allows. With the ability to quickly print and transfer designs, businesses can cater to fast-moving trends in fashion and consumer preferences. This efficiency is crucial in today’s market, where customers demand quicker service without sacrificing quality. Therefore, adopting DTF printing can help businesses remain competitive, fulfilling orders promptly while offering cutting-edge custom textile solutions.

The Impact of Eazydtf’s Investment on DTF Printing

Recently, Eazydtf’s substantial investment in large-format DTF printers has marked a pivotal moment in the growth of DTF technology. By enhancing their production capacity, they can now accommodate the increasing demand for high-quality, customized prints. This investment not only reinforces Eazydtf’s position in the market but also serves as a catalyst for smaller companies exploring DTF printing technology. As DTF becomes more widely adopted, we are likely to see a ripple effect throughout the textile industry, with more players capitalizing on the benefits of this printing method.

Moreover, Eazydtf’s strategic focus on quick order fulfillment, with same-day shipping capabilities, demonstrates the rising consumer expectation for efficiency. This ability to deliver quickly is crucial for businesses looking to gain a competitive edge, particularly in the realm of e-commerce and custom orders. As more companies follow Eazydtf’s lead, the landscape of textile printing could shift dramatically, creating new opportunities and challenges in the industry.

Snuggle DTF: A New Era of User-Friendly Platforms

The launch of Snuggle DTF is a groundbreaking development that reflects the growing demand for user-friendly platforms within the textile printing space. This web-to-print platform is designed to streamline the ordering process, allowing customers to easily upload designs and place orders for DTF transfers. By simplifying the logistics involved in custom printing, Snuggle DTF caters to a wide range of users, from individual creators to small businesses, all seeking efficient solutions for their textile printing needs.

This initiative emphasizes the role of technology in enhancing customer experience in textile printing. Snuggle DTF not only makes printing more accessible but also encourages creativity among users who might have been intimidated by traditional methods. As businesses increasingly turn to efficient platforms like Snuggle, we are likely to witness an expansion of the DTF printing market, making it an attractive option for a broader audience.

Custom Solutions: Catering to Individual Creators with DTFPrinter

DTFPrinter’s introduction of custom transfer printing services indicates a noteworthy shift in the market towards personalized and unique designs. This aligns perfectly with the current trend of consumerism where individuals and small businesses seek to differentiate themselves through bespoke products. DTF technology empowers these creators by providing a high-quality means to produce custom designs that are both vibrant and durable, thus enhancing the appeal of their offerings.

This move not only opens up new avenues for hobbyists and entrepreneurs but also capitalizes on the growing trend of DIY culture. By providing easy access to custom transfer solutions, DTFPrinter facilitates the creative ambitions of individuals while also streamlining the process of bringing their ideas to life. As the demand for customization continues to rise, companies like DTFPrinter are ideally positioned to thrive in this rapidly evolving market.

Innovative Technologies Shaping the Future of DTF Printing

The continual advancement in printing technologies, such as Mimaki’s new UJV300DTF-75, showcases the innovative spirit within the DTF printing industry. This state-of-the-art printer allows for UV DTF printing, which enhances productivity and versatility by enabling high-quality prints on various substrates. Such innovations not only push the boundaries of what DTF printing can achieve but also attract more businesses to explore this printing method, given its potential for exceptional results.

Moreover, these technological advancements are crucial in meeting the ever-growing consumer demands for unique and personalized products. As more printers evolve to adopt such capabilities, the competitive landscape of textile printing will likely be redefined. Companies that invest in cutting-edge technology like DTF are not only enhancing their operational capabilities but are also ensuring that they can offer the diverse and customized solutions that customers increasingly expect.

Frequently Asked Questions

What are DTF transfers and how do they work in textile printing?

DTF transfers, or Direct-to-Film transfers, involve a unique process where designs are printed onto a special film and then heat transferred onto textiles. This method is celebrated for its ability to produce vibrant colors and durable prints on a wide variety of fabrics, making it a popular choice in modern textile printing.

What are the advantages of DTF printing over traditional methods?

DTF printing offers several advantages, including quicker production times, the ability to print on diverse fabrics, and excellent color vibrancy. Unlike traditional textile printing methods, DTF allows for complex, customizable designs with minimal setup costs, making it suitable for both small-scale and bulk orders.

How is DTF transfer technology advancing in the custom textile solutions market?

The custom textile solutions market is embracing DTF transfer technology due to its efficiency and versatility. Companies like Eazydtf and Snuggle have invested in DTF printing innovations that enhance production capacity and simplify the ordering process for custom designs, catering to both individual consumers and businesses.

Can DTF printing be used for hobbyists and small business owners?

Yes, DTF printing is ideal for hobbyists and small business owners seeking high-quality and customizable textile prints. Services like DTFPrinter offer custom transfer solutions that empower creators to easily produce unique designs without the complexities of traditional printing methods.

What innovations are driving the future of DTF printing technology?

Innovations such as the introduction of advanced DTF printers by companies like Mimaki are paving the way for the future of DTF printing. New technologies involving UV inks and enhanced printing capabilities are significantly improving productivity and expanding the creative potential for various substrates in textile printing.

Why is DTF printing gaining popularity in the textile printing industry?

DTF printing is gaining popularity due to its combination of quality, efficiency, and user-friendliness. As demand for custom designs and quick turnaround times increases, DTF technology is proving to be a leading solution that addresses modern printing needs in the textile industry.

| Key Points | Details |

|---|---|

| DTF Printing Overview | Involves printing designs on a special film that transfers onto textiles. Known for vibrant colors and durability across fabric types. |

| Eazydtf’s Investment | Eazydtf invested in ten large-format DTF printers to meet growing demand, enabling same-day shipping across the U.S. |

| Snuggle DTF Platform | A web-to-print platform launched by Snuggle to streamline ordering for customers emphasizing DTF’s efficiency. |

| Custom Solutions by DTFPrinter | Targets hobbyists with high-quality custom transfer printing services, addressing market demand for personalized products. |

| Innovations by Mimaki | Mimaki’s UJV300DTF-75 printer introduces UV inks for high-quality prints on various materials, enhancing DTF capabilities. |

Summary

DTF Transfers represent the future of textile printing with their innovative approach to producing high-quality and vibrant prints. This technology is rapidly gaining acceptance, thanks to its versatility and durability on diverse fabrics. Recent strategic investments by key players like Eazydtf, along with the launch of customer-centric platforms such as Snuggle DTF, highlight the industry’s shift towards DTF printing solutions that facilitate quick and effective customization. Moreover, advancements from manufacturers like Mimaki showcase ongoing innovations that broaden the applications of DTF technology across various materials beyond traditional textiles. As the textile market becomes more focused on efficiency and rapid turnaround, DTF Transfers will undoubtedly continue to lead the charge in reshaping the industry, appealing to both commercial sectors and individual creators who seek high-quality, personalized printing solutions.